HVDC converter with neutral-point connected zero-sequence dump resistor

A converter and series connection technology, applied in the field of power electronic converters, can solve the problems of increasing the energy transfer resistor 18, the hardware size of the converter, the increase in weight and cost, etc., and achieve the simplification of operation procedures and control schemes, weight and Cost reduction, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

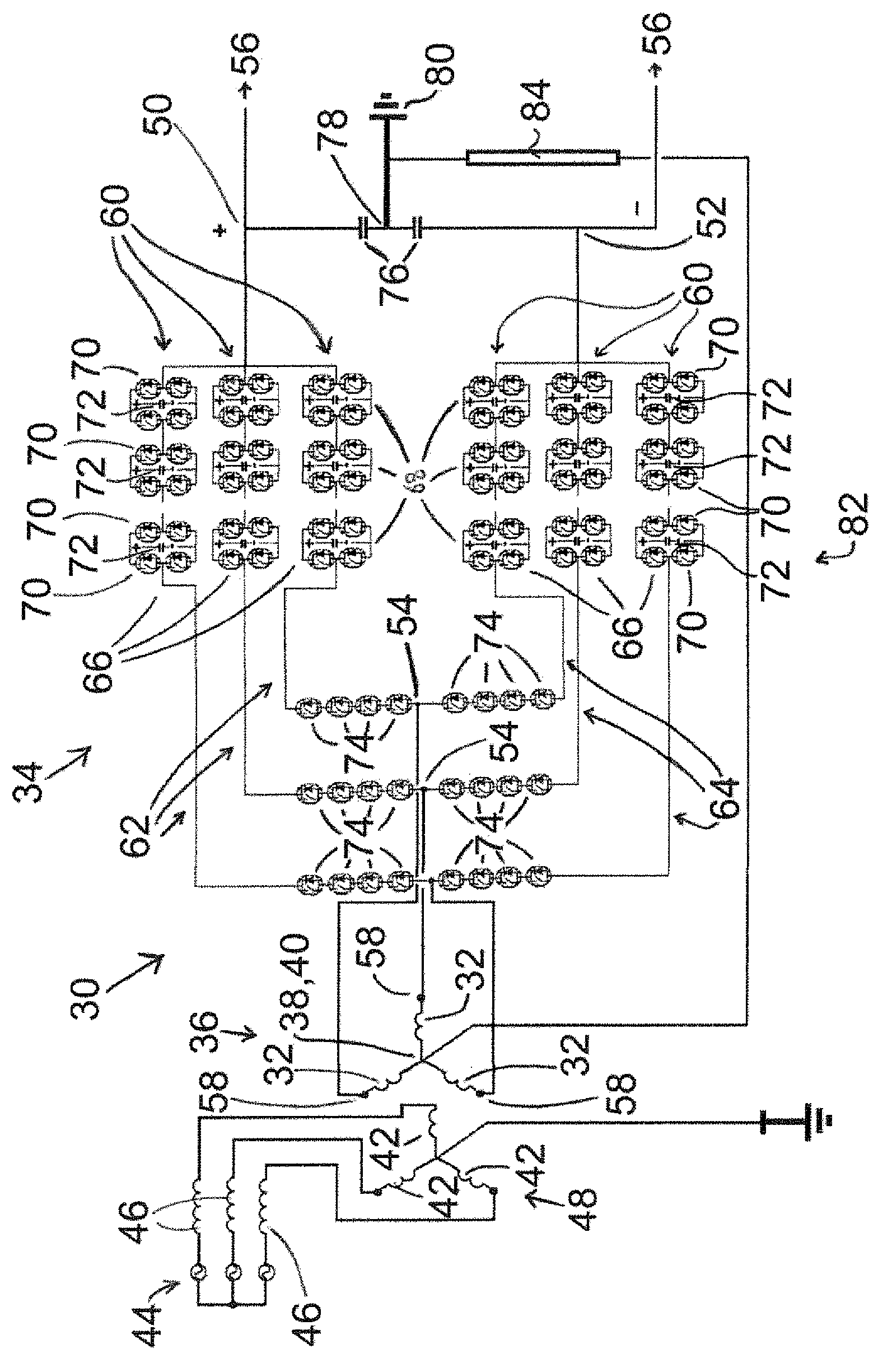

[0045] image 3 A power electronic converter 30 according to one embodiment of the invention is shown.

[0046] The power electronic converter 30 includes three phase elements 32 and a converter unit 34 .

[0047] Each phase element 32 includes a transformer winding. The three phase elements 32 define a first star connection 36 in which a first end 38 of each phase element 32 is connected to a common node 40 of the first star connection 36 . The first star connection 36 defines the secondary side of the transformer, wherein each transformer winding of the first star connection 36 is mutually coupled with a corresponding primary winding 42 at the primary side 42 of the transformer, each primary winding via a line inductor 46 are connected to the respective phases of the three-phase AC network 44 . This enables each phase element 32 to be associated in use with a corresponding phase in the three-phase AC network 44 . The primary winding 42 at the primary side of the transfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com