Spiral water cooling excitation mechanism of intelligent boring bar driven by embedded giant magnetostrictive material

A giant magnetostrictive and boring bar technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, metal processing machinery parts, etc., can solve the impact of machine tool spindle dynamic balance, magnetic field cycle Insufficient uniform orientation, poor cooling effect, etc., to achieve the effect of simple structure, preventing the influence of temperature, and facilitating processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

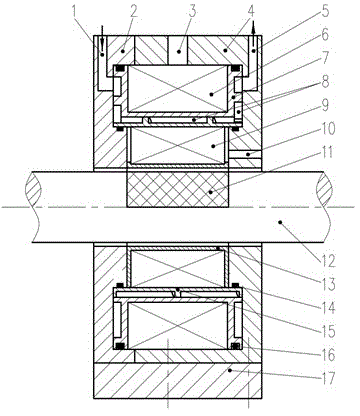

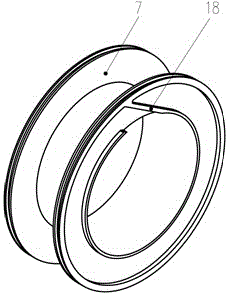

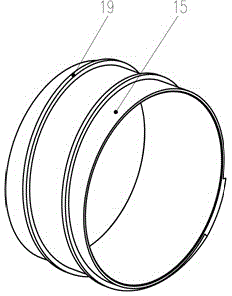

[0018] Such as Figure 1-Figure 4 As shown, the present invention includes a coil end cover 2, a coil housing 4, a large coil 6, a large coil bobbin 7, a spiral water cavity 8, a small coil 9, a giant magnetostrictive material block 11, a boring bar 12, and a small coil bobbin 13 , small sealing ring 14, sealing sleeve 15, large sealing ring 16, coil base 17, water-proof boss 18; the outer cylindrical surface of boring bar 12 is axially provided with grooves, and giant magnetostrictive material blocks are housed in the grooves 11. The small bobbin 13 is set on the shaft section of the boring bar 12 equipped with the giant magnetostrictive material block 11, the small coil 9 is wound on the small bobbin 13, and the sealing sleeve 15 with the external thread 19 is installed on the small coil Outside the frame 13, the large coil frame 7 with spiral water-proof bosses 18 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com