Installation tooling of condenser

A technology for assembling tooling and condensers, applied in the field of assembling tooling, can solve the problems of high cost of positioning tooling, low work efficiency, complicated design, etc., and achieve the effects of low cost, compact structure, and simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

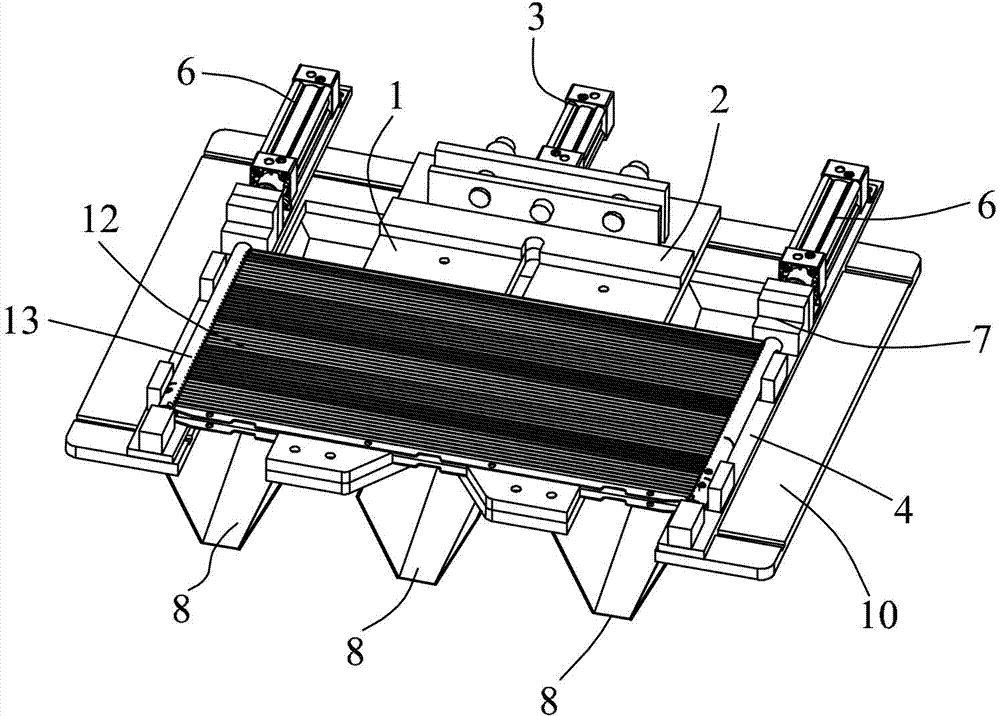

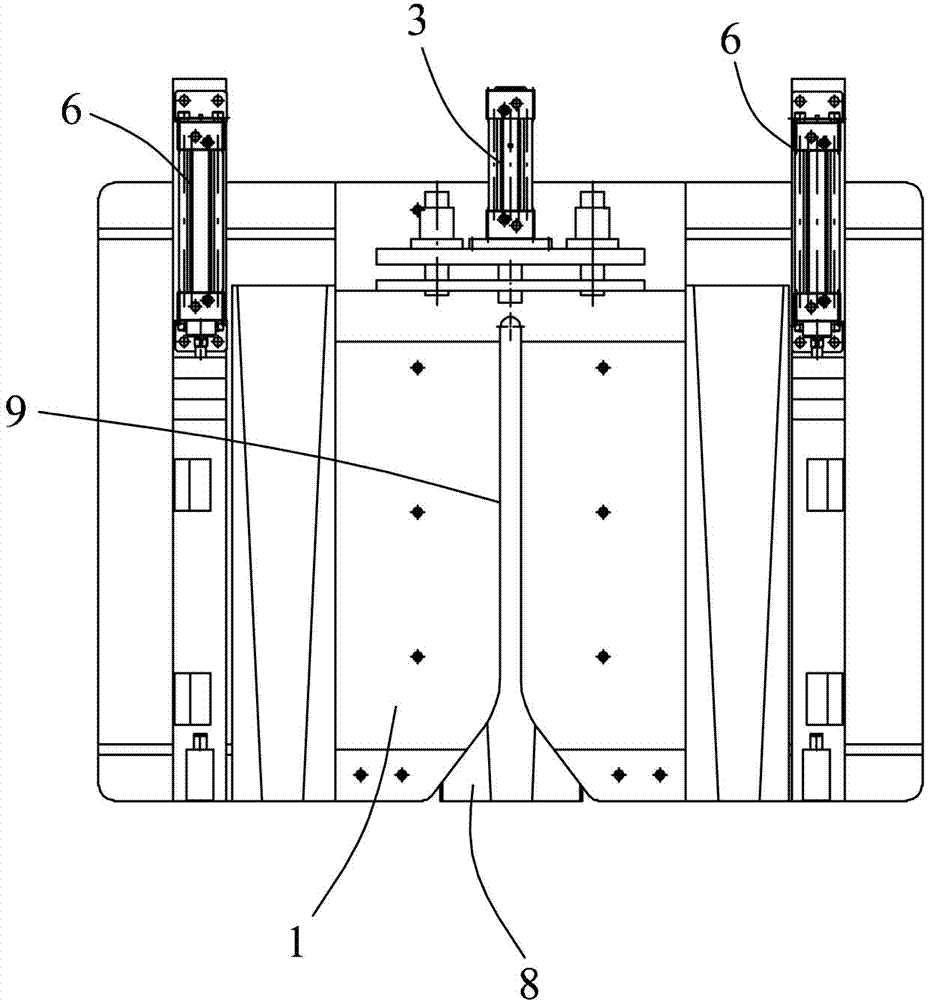

[0018] Such as Figure 1 to Figure 3 As shown, the condenser assembly tooling of this embodiment is used to bundle the condenser before brazing and put it into the blocking cap. The assembled condenser includes a core body 12 and two liquid collecting pipes located on both sides of the core body 12 13.

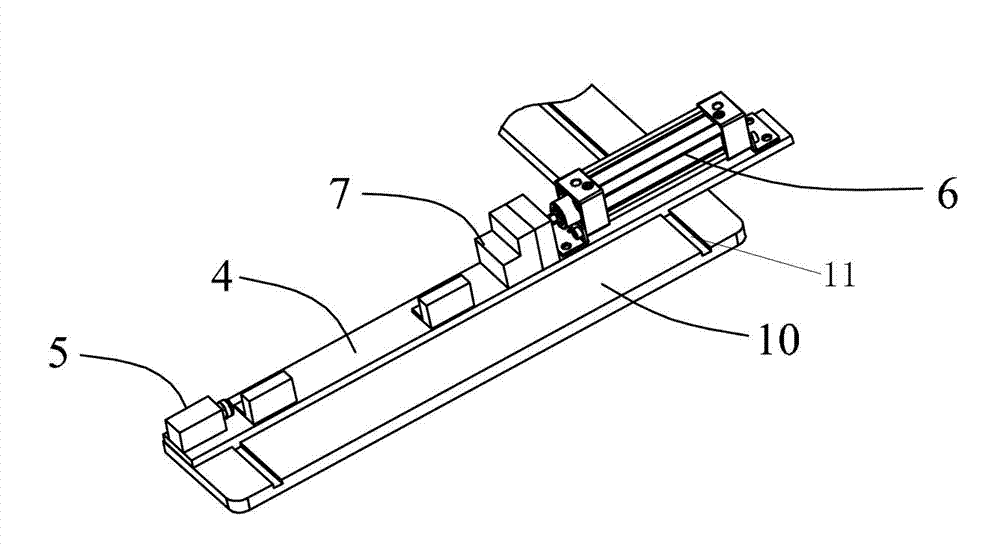

[0019] The condenser assembly tooling includes a core pressing unit and plug cap installation units located on both sides of the core pressing unit. Wherein, the core compacting unit is used to compress the core 12 to facilitate binding the core 12 with iron wires, and the plug cap installation unit is used to install the plug cap on the liquid collecting pipe 13 .

[0020] The core pressing unit includes a platform 1 for positioning and placing the core 12, a pressing plate 2 that is slidably arranged on the platform 1, pressing the core 12 along the elongation direction of the liquid collecting pipe 13, and a pressing cylinder 3 that drives the pressing plate 2 to move. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com