Mounting tool for engine fuel injector

A technology for installing tools and injectors, which is applied to the field of engine injector installation tools, can solve problems such as fuel leakage, low efficiency, and fuel injectors affect engine performance, and achieve the effect of improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

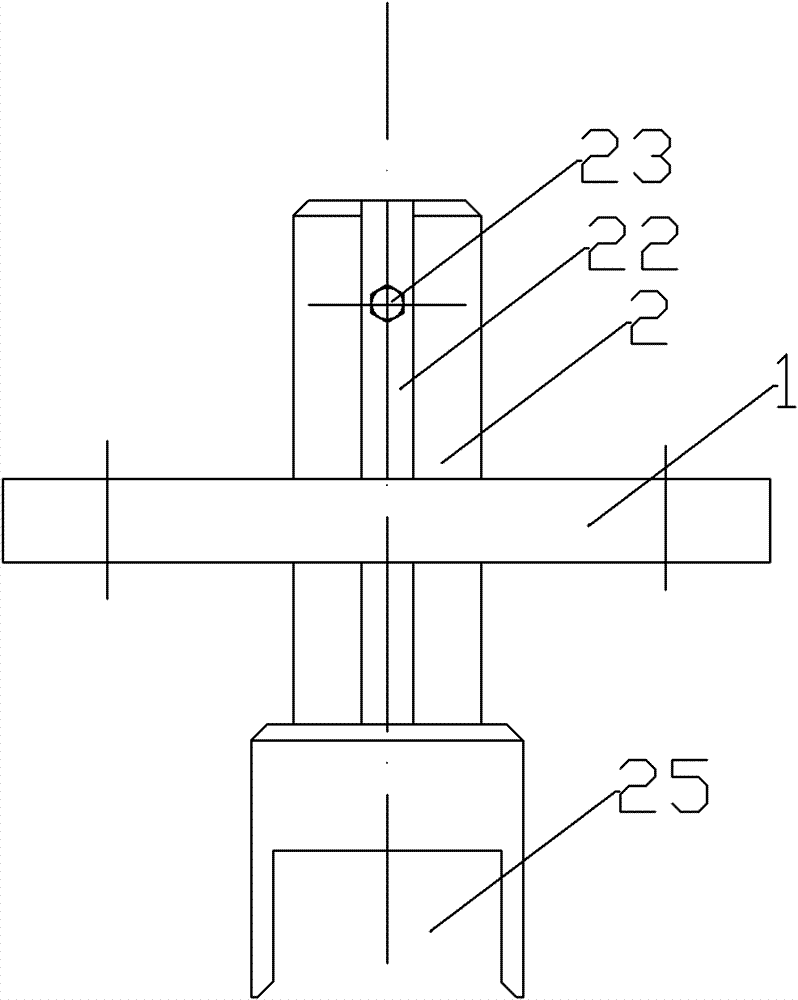

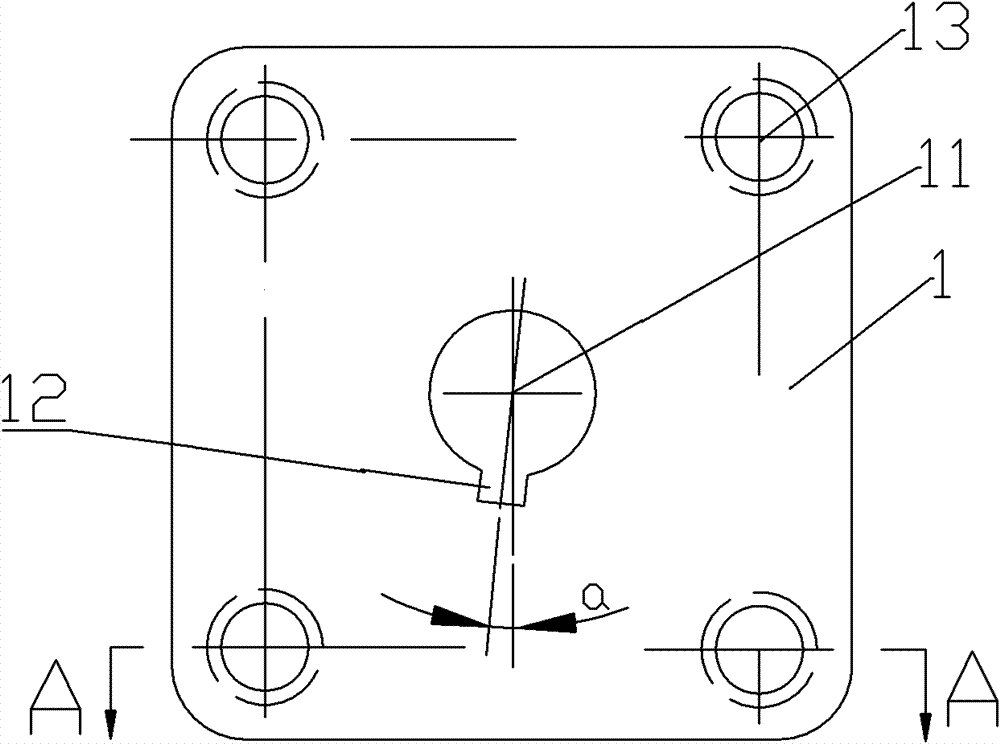

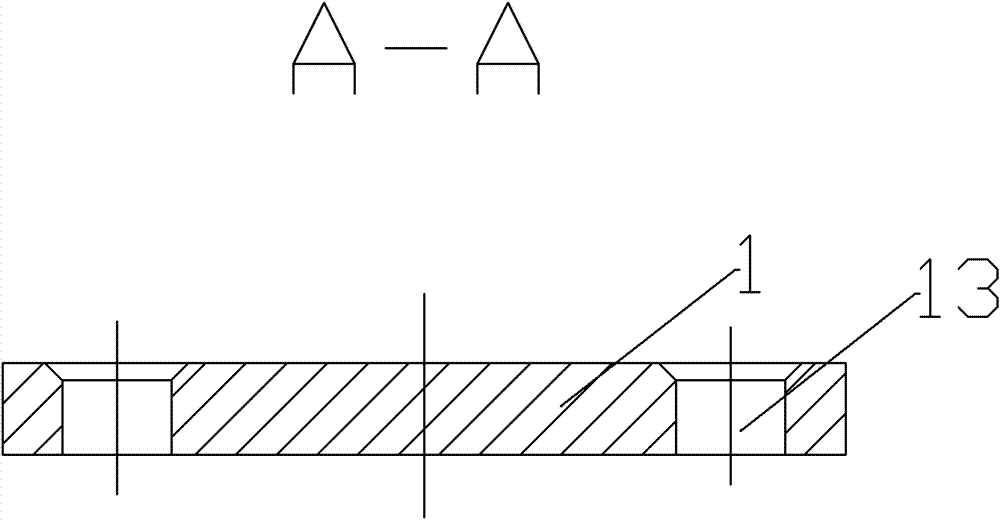

[0020] see figure 1 , the engine injector installation tool includes: a correction plate 1 and a correction shaft 2. Among them, such as Figure 1 to Figure 3 As shown, the correction plate 1 is in the shape of a square plate, with a shaft passing hole 11 in the center, and one or more rectangular key grooves 12 are arranged in the circumferential direction of the passing shaft hole 11; The four through holes 13 correspond to the valve stems around the fuel injector mounting hole 31 on the cylinder head. The direction of the keyway 12 of the correction plate 1 forms a certain angle a with the vertical direction (ie, the line connecting the centers of the two through holes 13 in a row).

[0021] Such as Figure 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com