Mobile maintenance car for belt conveyors

A technology for belt conveyors and maintenance vehicles, which is applied to workshop equipment, manufacturing tools, etc., can solve the problems of high labor intensity, long maintenance time, and low work efficiency, so as to improve maintenance efficiency, reduce investment costs, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

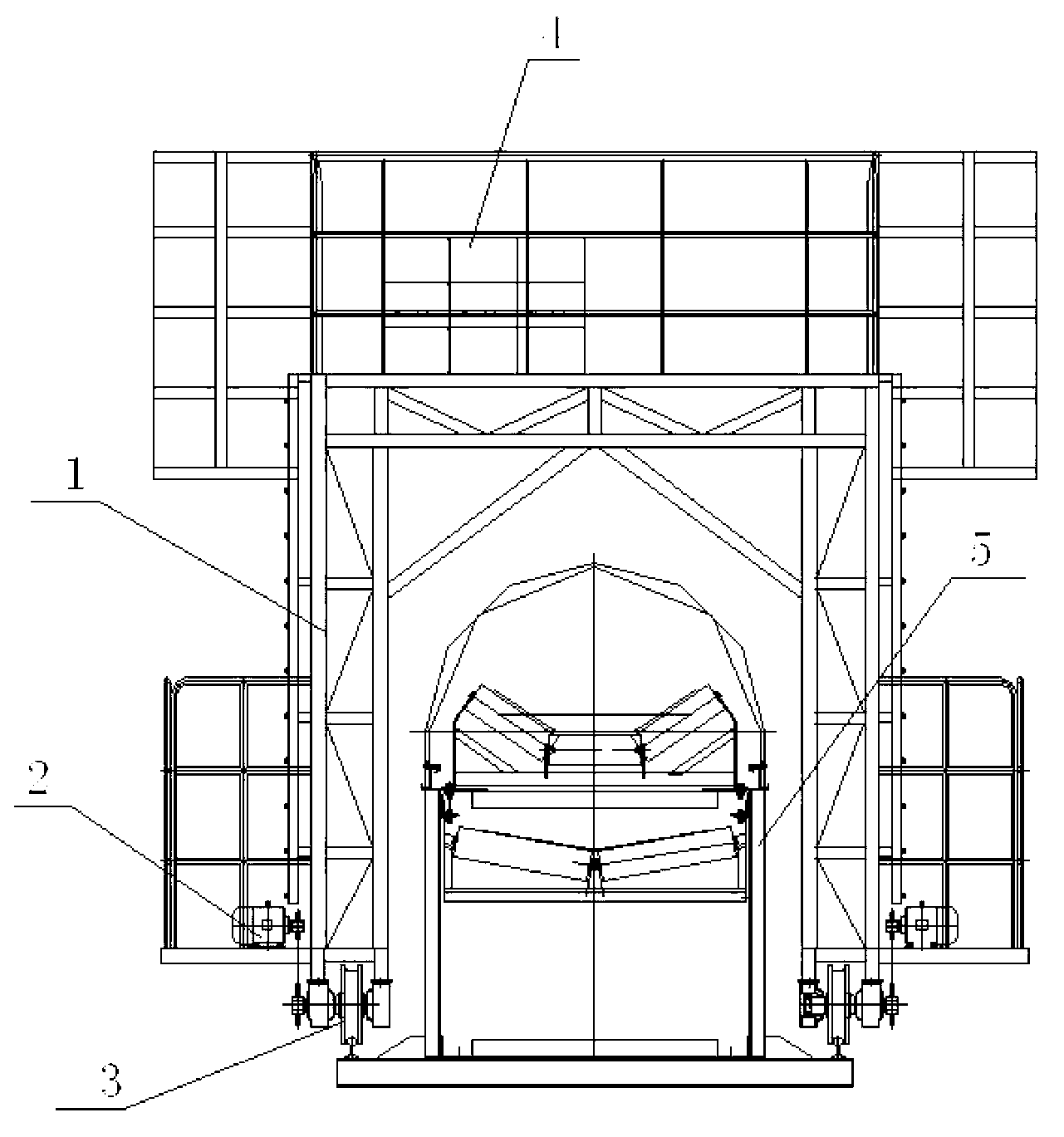

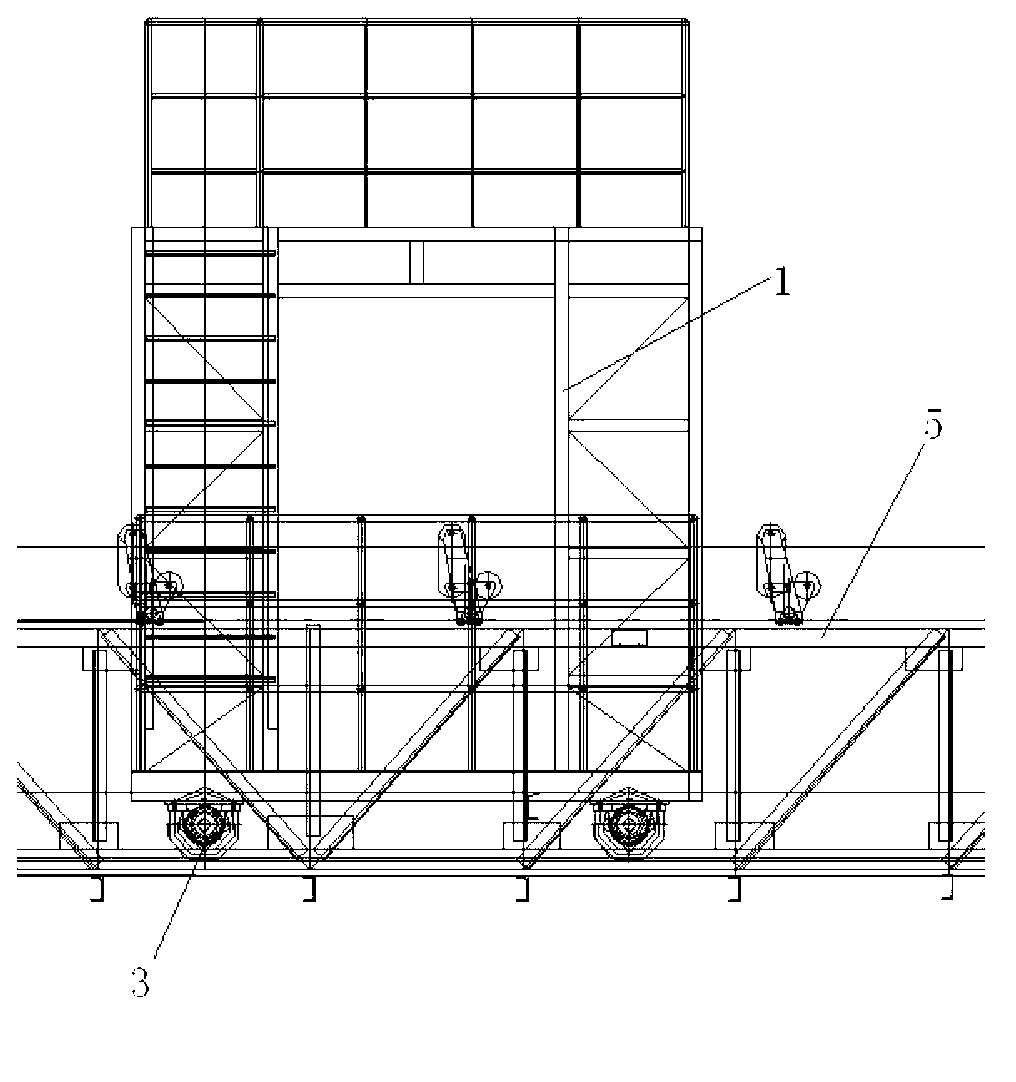

[0019] like figure 1 , figure 2 As shown, it includes maintenance vehicle body 1, driving device 2, running device 3, charging power supply 4, lighting system and control system (not shown in detail in the figure) and other parts:

[0020] The maintenance vehicle body 1 includes a spanning ladder, an maintenance platform, a loading platform, etc. The maintenance vehicle body 1 is welded or bolted by profiles, straddles the upper part of the belt conveyor 5, and is the main part of the mobile maintenance vehicle.

[0021] The driving device 2 includes a motor (or internal combustion engine), a transmission, a brake, a driving wheel, etc., and the running device 3 includes a wheel, which is connected to the wheel through a chain, and is an important part of the maintenance vehicle.

[0022] The charging power supply 4 includes battery packs, chargers, etc., and is an important part of the mobile maintenance vehicle, providing energy for the maintenance vehicle to travel.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com