Secondary bonding forming method of structural part with curvature

A technology for secondary bonding and structural parts, which is applied in the field of secondary bonding and molding of structural parts with curvature, can solve the problems of poor product quality stability and prone to dents in seams, so as to improve product stability and reduce product The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

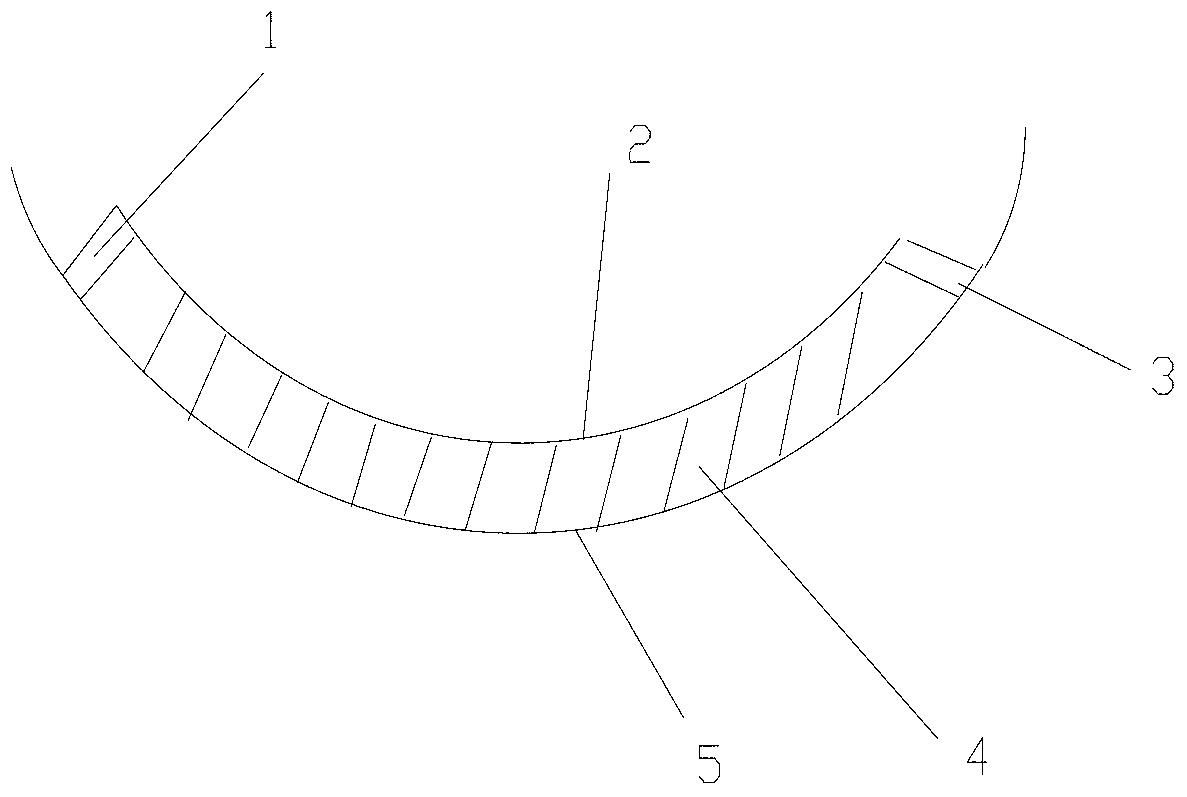

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings. see figure 1 , figure 1 Structural diagram of glued parts. 1 is the cured expansion film, 2 is the inner skin, 3 is the cured expansion film, 4 is the honeycomb, and 5 is the outer skin.

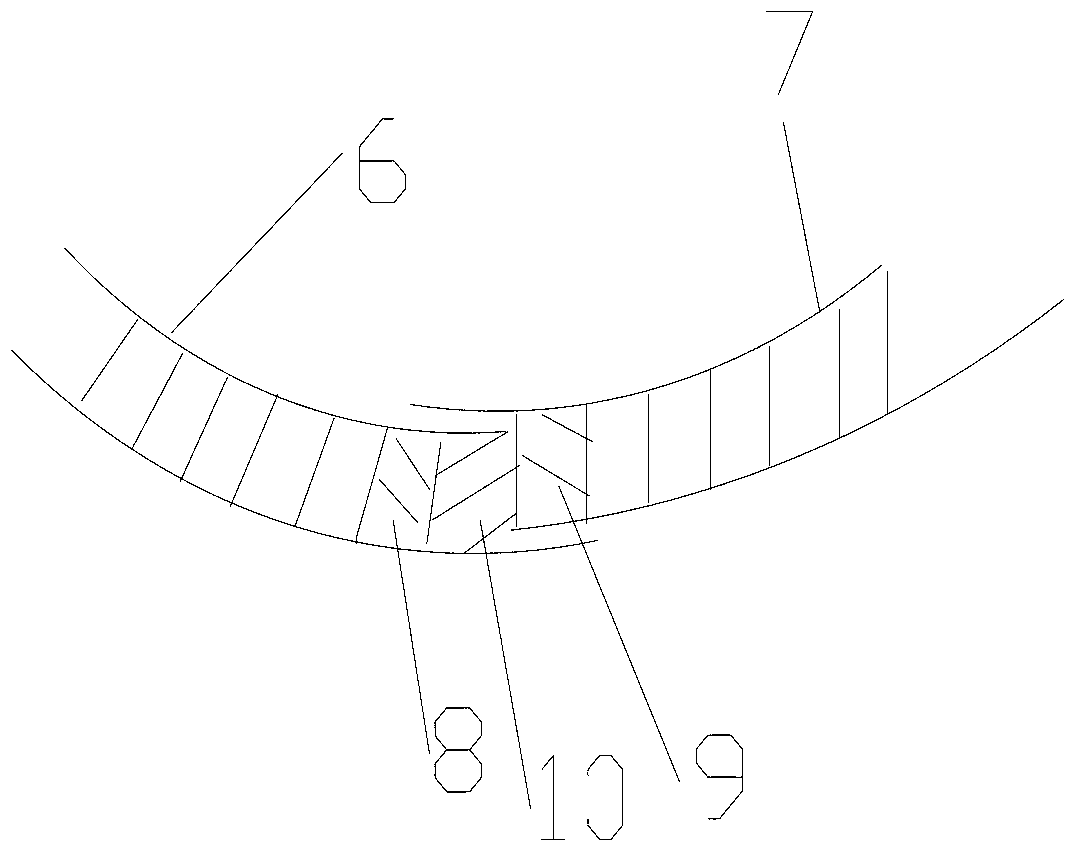

[0029] join figure 2 , figure 2 It is the secondary bonding structure diagram of the bonding parts. 6 and 7 are glued parts, 8 and 9 are cured expansion film, and 10 is the J-94 expansion film added when the secondary glue joint is closed.

[0030] 1) Forming of each glued component

[0031] Surface treatment of inner and outer skins (aluminum) 2 and 5: chromic acid anodizing treatment for inner and outer skins (aluminum) 2 and 5, spraying J on the inner and outer skins (aluminum) -100 primer.

[0032] Adhesive assembly: ① Lay the outer skin 5 on the metal forming tool first, ② Lay the high-temperature curing structural adhesive film J-99B on the outer skin 5, ③ Lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com