Pneumatic tire

A technology of pneumatic tires and tires, which is applied in the directions of pneumatic tires, reinforcement layers of pneumatic tires, tire parts, etc., to achieve the effect of excellent driving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11~17

[0128] Embodiment 11~17, existing example 11

[0129] Examples 11 to 17 and Conventional Example 11 relate to the pneumatic tire of the second present invention.

[0130] As test tires, each of Examples 11 to 17 and Comparative Example 11 produced ten test tires with a structure of two belt layers and two carcass layers, and the tire size was 195 / 65R1591H (15×6J). .

[0131] In each of the test tires, a film having a thermoplastic resin of N6 / 66 and having a thickness of 130 μm was used as a film mainly composed of a thermoplastic resin to form an inner liner.

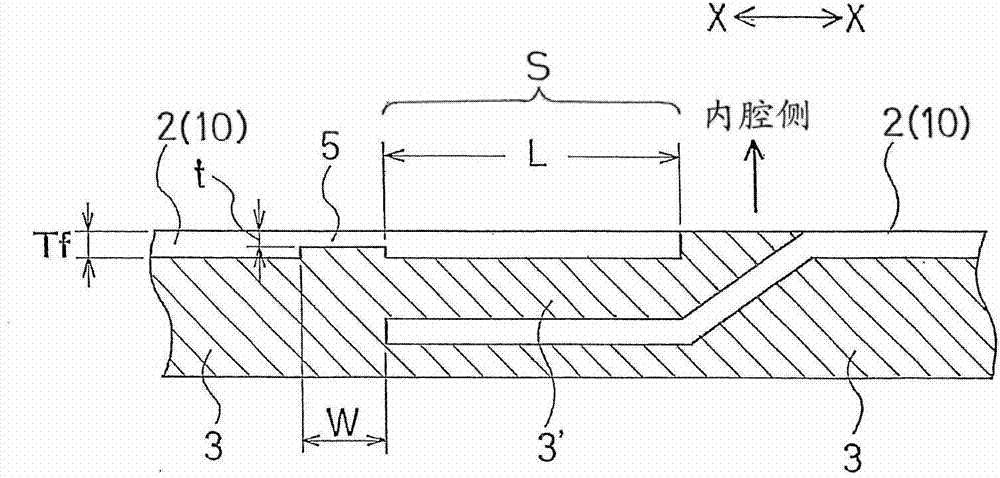

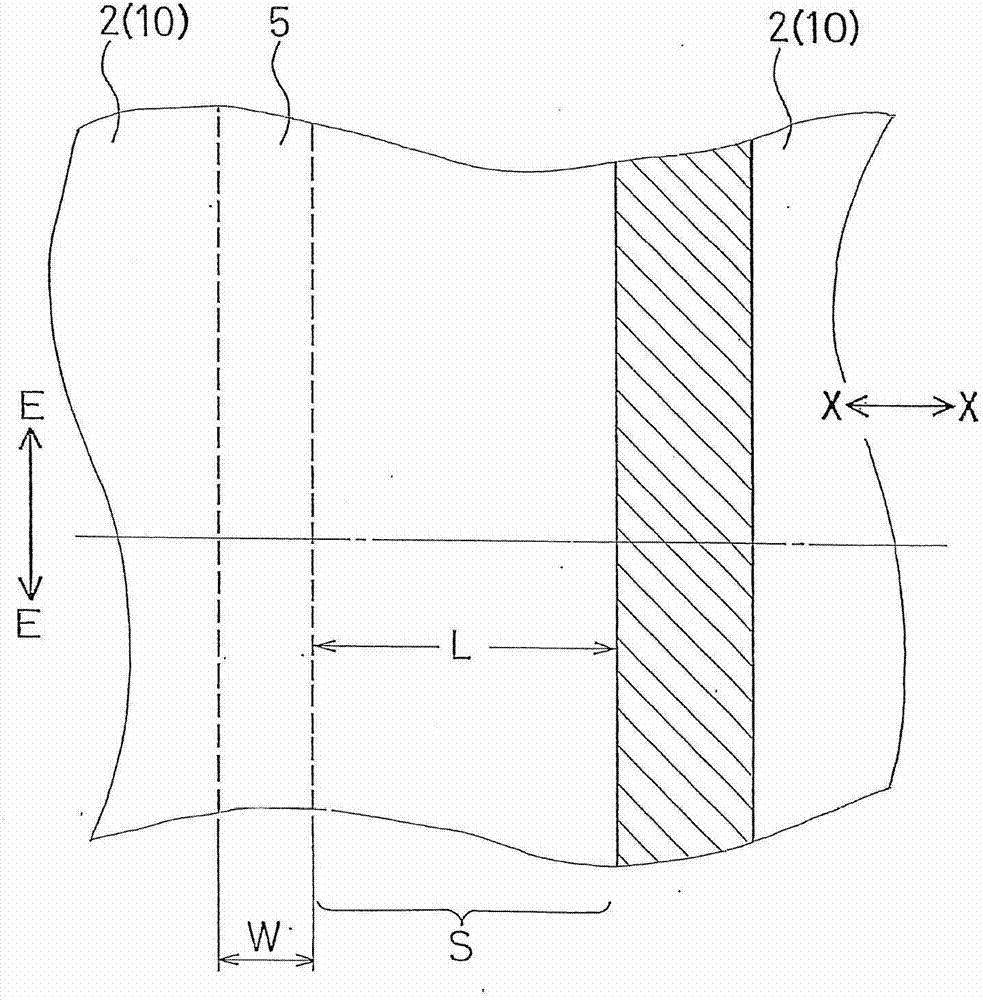

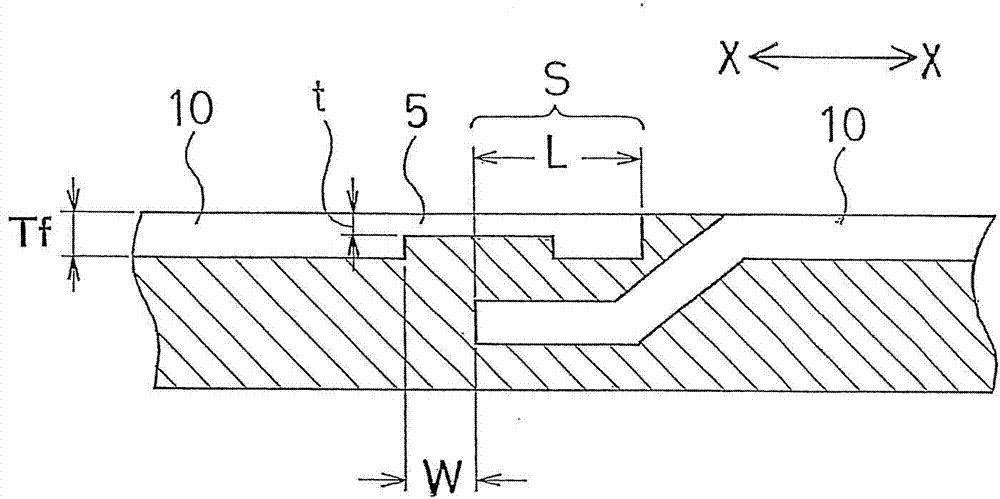

[0132] The films of Examples 11 to 17 were each cut into a desired length×width, and laser treatment was repeatedly performed along the tire width direction on both ends of the tire circumferential direction to make it into the thin film shown in Table 2. thickness of. Conventional Example 11 is a film in which no thin portion is specially provided.

[0133] For each seam S, the length (Lmm) of the seam, the side c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com