L-lactic acid production method and special Bacillus sp. therefor

The technology of Bacillus sp. and Bacillus fermentum is applied in the field of special Bacillus sp. strains, which can solve problems such as failure to meet industrialization requirements, and achieve the effects of simplifying post-processing processes, reducing fermentation costs, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]Example 1, Isolation and Identification of Bacillus sp. WL-S20

[0031] 1. Separation of WL-S20

[0032] Screening medium (g / L): glucose 10.0, yeast powder 5.0, polypeptone 5.0, K 2 HPO 4 ·3H 2 O 1.0, MgSO 4 ·7H 2 O 0.2, NaCl 50, distilled water 900ml, high temperature sterilization at 115°C for 20 minutes, then add high temperature sterilized 10% (w / v) Na 2 CO 3 100ml. For solid medium, 0.1-0.2 g / L agar needs to be added.

[0033] Mud samples were obtained from the edge of the Ordos Saline-Alkali Lake in Inner Mongolia. Weigh 5g of mud sample into a 250ml Erlenmeyer flask, add 100ml of screening medium, mix thoroughly, dilute 10,000 times with screening medium and spread on solid screening medium, culture at 37°C for 3 days, and inoculate the grown single colony into A test tube containing 4ml of selection medium was cultured statically at 37°C for 24 hours. At the end of the culture, take the fermentation broth, centrifuge at 6,000 rpm with a centrifugal rad...

Embodiment 2

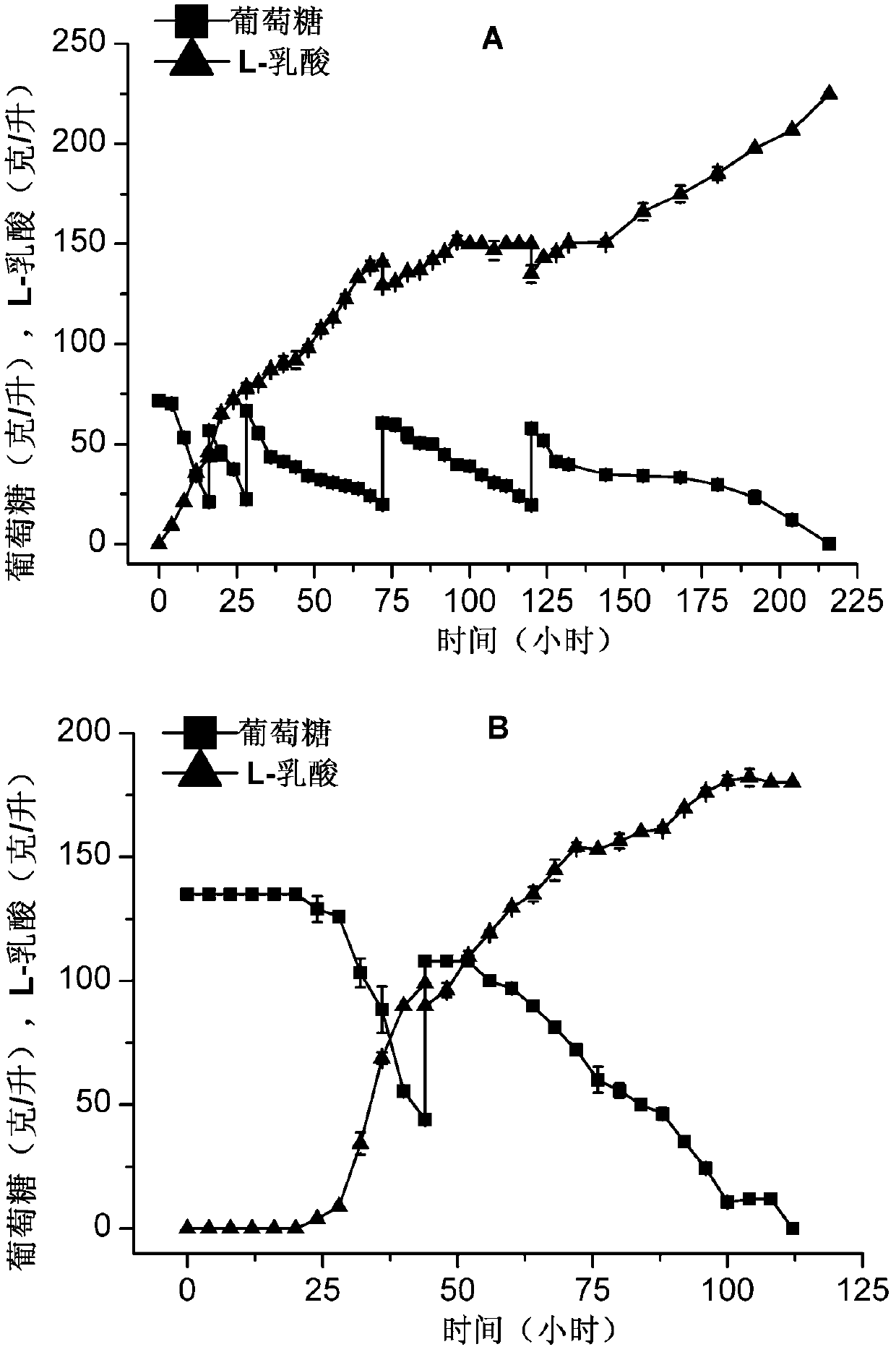

[0044] Embodiment 2, the application of Bacillus sp. WL-S20 CGMCC NO.5634

[0045] method one:

[0046] 1. Fermentation

[0047] The composition of the medium used in this embodiment is as follows:

[0048] Seed medium (g / L): glucose 10.0, yeast powder 5.0, polypeptone 5.0, K 2 HPO 4 ·3H 2 O 1.0, MgSO 4 ·7H 2 O 0.2, NaCl 50, distilled water 900ml, high temperature sterilization at 115°C for 20 minutes, then add high temperature sterilized 10% (w / v) Na 2 CO 3 100ml.

[0049] Fermentation medium (g / L): Glucose 80, peanut meal (Beijing Kangmingwei Medium Technology Co., Ltd.) 20, MgSO 4 ·7H 2 O 0.35, K 2 HPO 4 ·3H 2 O2,CH 3 COONa 1, MnSO 4 ·H 2 O 0.03. Sterilize at 115°C for 20 minutes.

[0050] The method for producing L-lactic acid by fermentation method of the present invention comprises the following steps:

[0051] 1), activation culture: the preserved Bacillus sp. (Bacillus sp.) WL-S20 CGMCC NO.5634 glycerol bacterium liquid is inoculated into a test tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com