Flow-constant cam pump rotor profile and generation method thereof

A rotor profile and constant flow technology, applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve problems such as noise, pulsation at joints, and inability to ensure stable and constant delivery of media, so as to reduce wear and prolong Service life, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

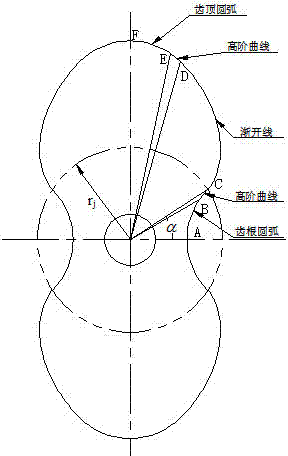

[0010] The present invention is a constant flow cam pump rotor profile and its generation method, such as figure 1 As shown, the rotor profile of the cam pump is completely symmetrical about the axis of symmetry, the main profile of the rotor adopts the involute CD, the dedendum and the top part are composed of the first arc segment AB and the second arc segment EF, and the transition curve is The first high-order curve BC and the second high-order curve DE that carry on the involute and circular arc, the five sections of curves are connected end to end to form 1 / 4 of the rotor profile, and the profile line of the entire cam pump rotor is obtained according to the principle of symmetry.

[0011] like figure 1 As shown, the cam pump rotor adopts a two-dimensional tooth shape model, and the entire rotor profile adopts a completely symmetrical design. Smooth transition.

[0012] (1) The profile line of the cam pump rotor is a dedendum arc from the first point (A) to the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com