Tappet comprehensive gauge

A technology of comprehensive inspection tools and base plates, applied in the field of inspection tools, can solve the problems of harsh use environment, inability to tapper detection, complicated operation, etc., to improve detection efficiency, overcome the defects of traditional detection methods, and achieve high detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

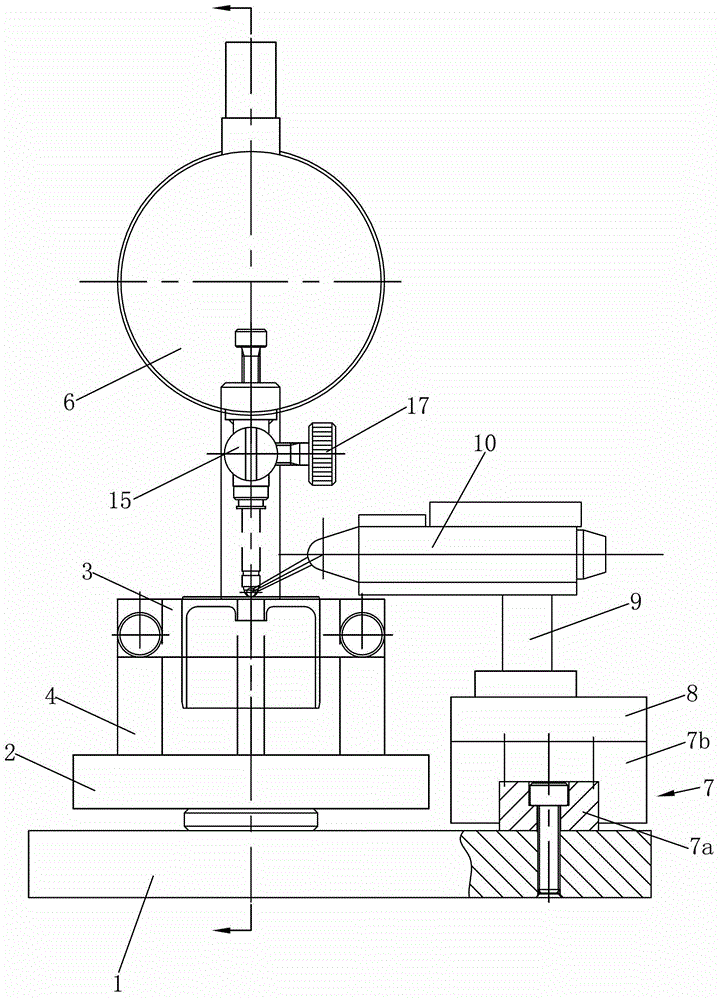

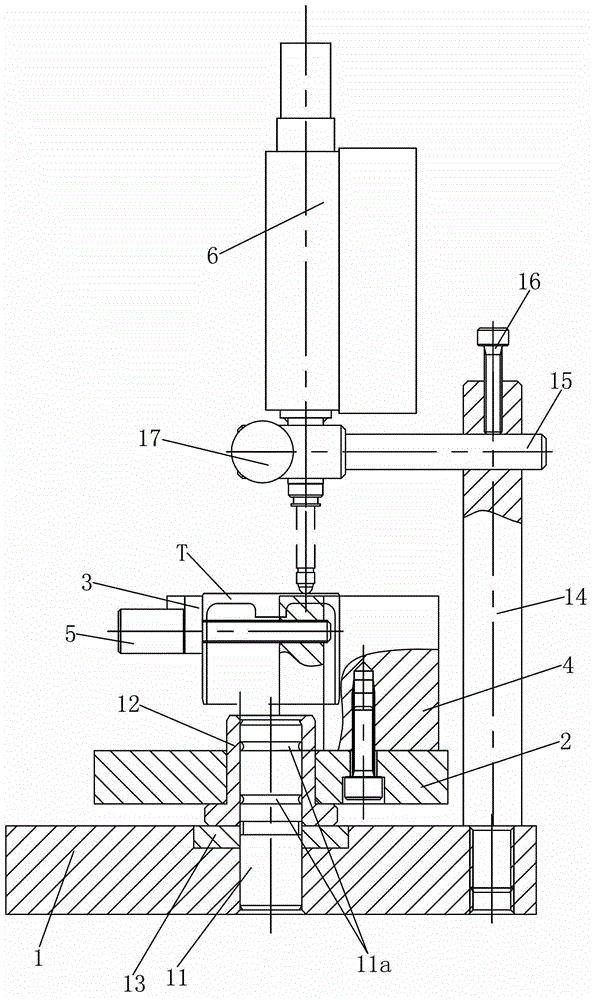

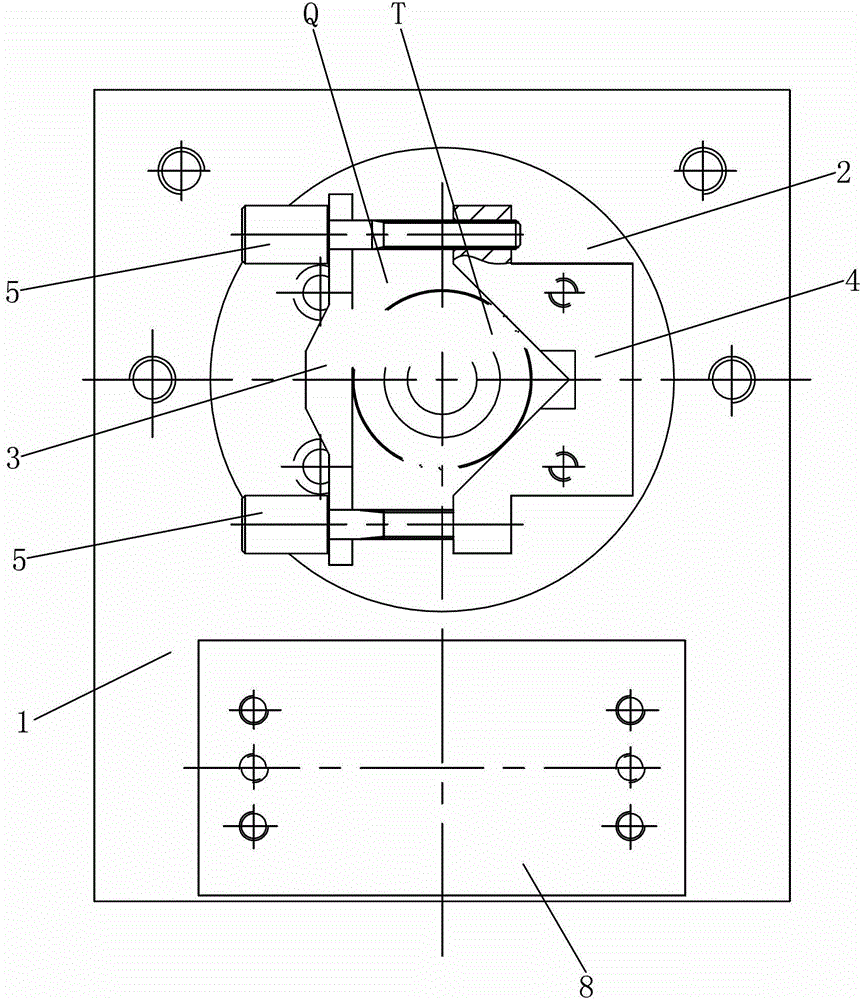

[0021] Such as figure 1 , 2 As shown in and 3, a tappet comprehensive inspection tool mainly consists of a base plate 1, a turntable 2, a clamping plate 3, a V-shaped block 4, a screw 5, a dial indicator 6, a linear slide table 7, a connecting plate 8, and a table seat 9. Lever dial indicator 10. The rotating assembly and the supporting assembly are composed. Wherein, the bottom plate 1 is a flat plate, which is a square plate in this embodiment. A turntable 2 is arranged horizontally above the bottom plate 1 , and the center of the turntable 2 is connected to the bottom plate 1 through a rotating assembly.

[0022] The rotating assembly is composed of a rotating shaft 11 , a shaft sleeve 12 and a bottom plate insert 13 , wherein the bottom plate insert 13 is fixed on the top surface of the bottom plate 1 . The shaft sleeve 12 is a two-stage stepped struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com