RTV (Room Temperature Vulcanization silicone rubber) hydrophobicity testing device

A test device and hydrophobicity technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of not being able to judge the antifouling performance of RTV coatings in a timely and accurate manner, and achieve safe and stable operation, convenient operation, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

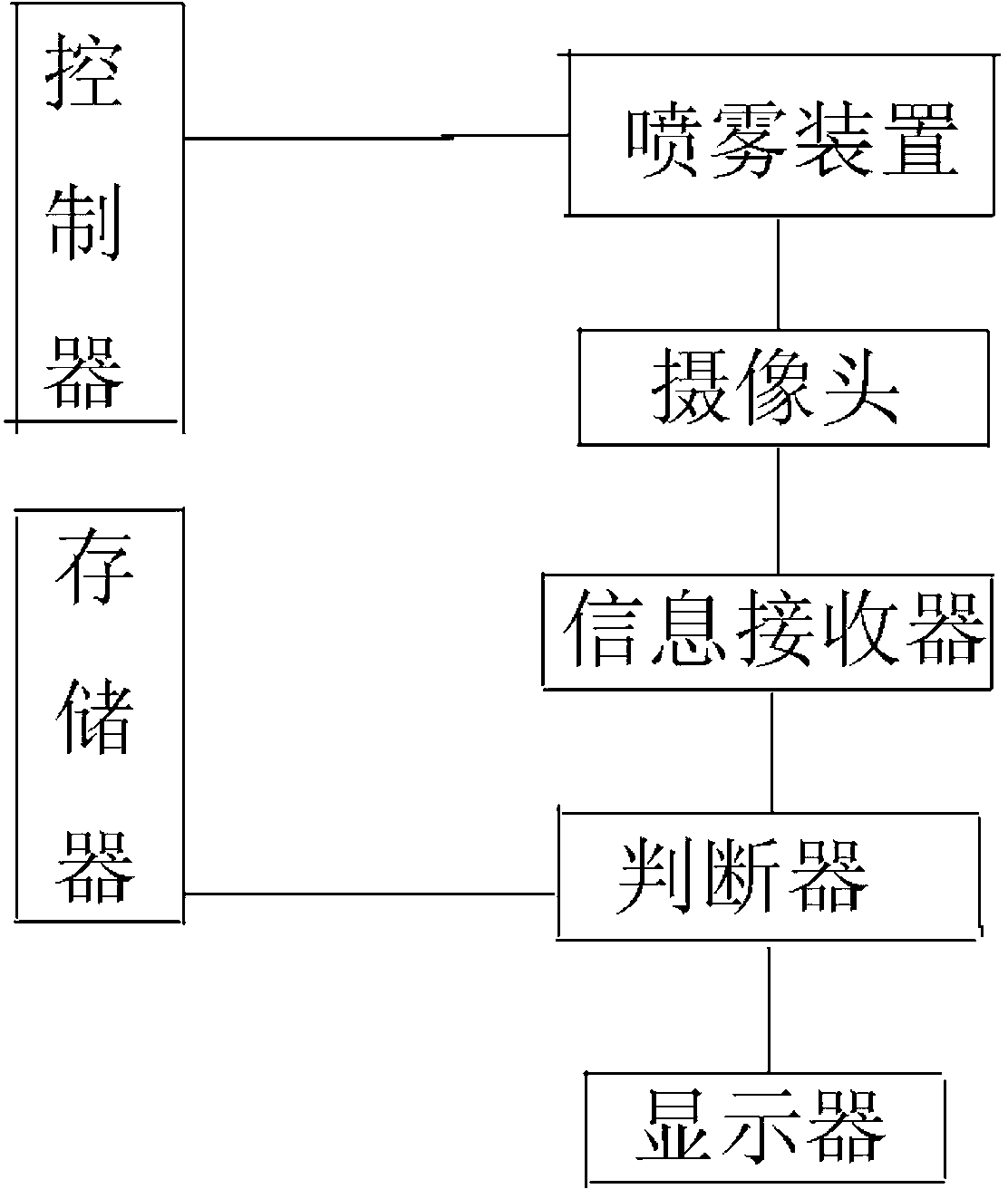

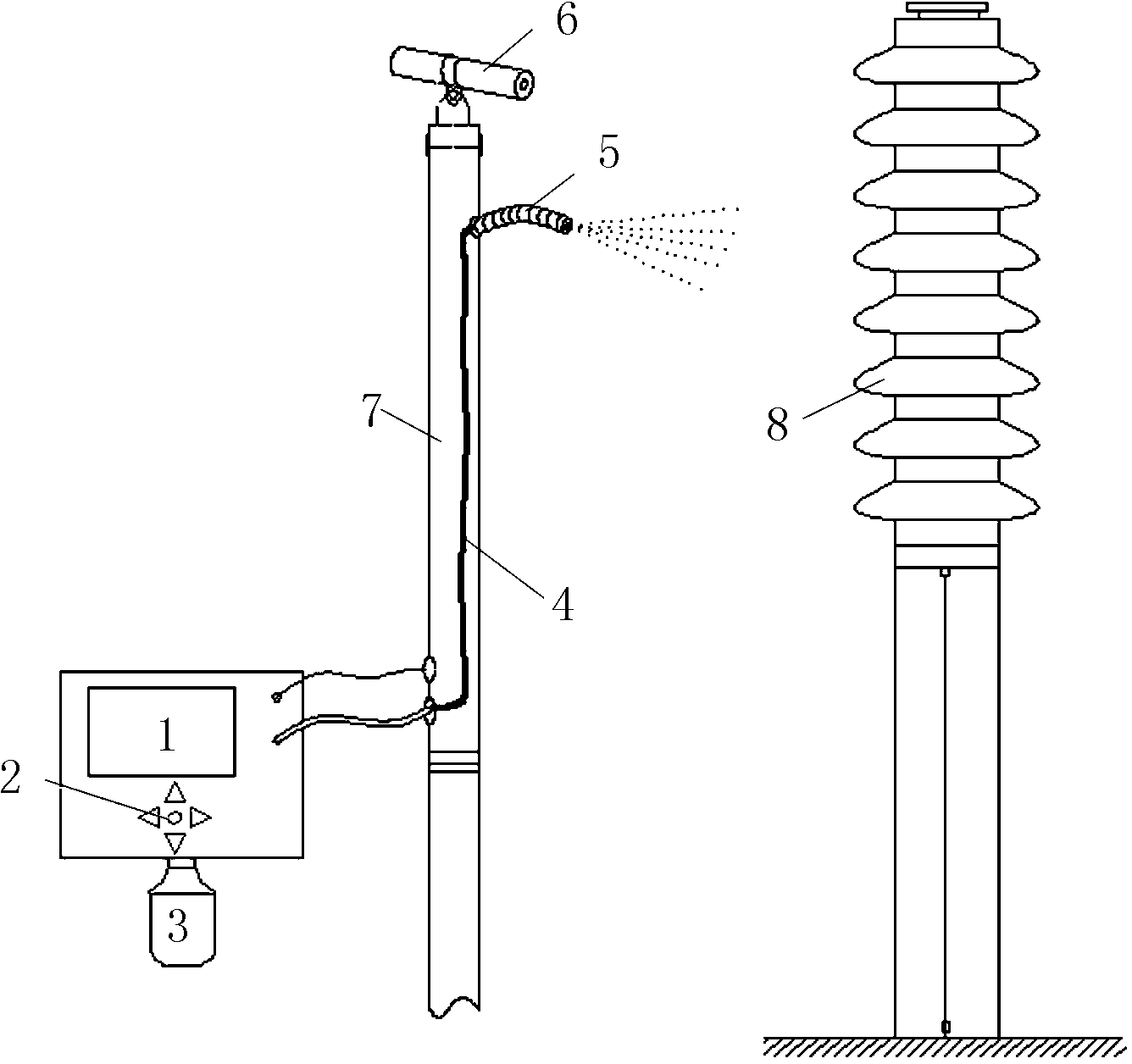

[0015] Set the memory, the standard picture of HC1-HC7 is stored in the memory; set the controller, control the spraying of the spray device; set the camera, record the camera or take pictures after spraying; set the information receiver, receive the hydrophobicity extracted after the camera records or takes pictures pictures; a judging device is set to compare and judge the hydrophobic picture received by the information receiver with the standard picture in the memory; a display is set to output and display the judging result of the judging device.

[0016] The spray device is as follows: the spray nozzle is fixed on the insulating rod, and the spray nozzle is connected to the kettle through the water pipe.

[0017] The camera is arranged on the insulating pole, and the camera is connected with the information receiver through the communication line.

[0018] The working process of the present invention is that the insulating tile coated with RTV is sprayed 40 times within 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com