Large-sized slide supporter with core overturning table

A slideway type and supporter technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of iron core specification restrictions, easy deformation, etc., to ensure product quality, prevent slipping, and improve process level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

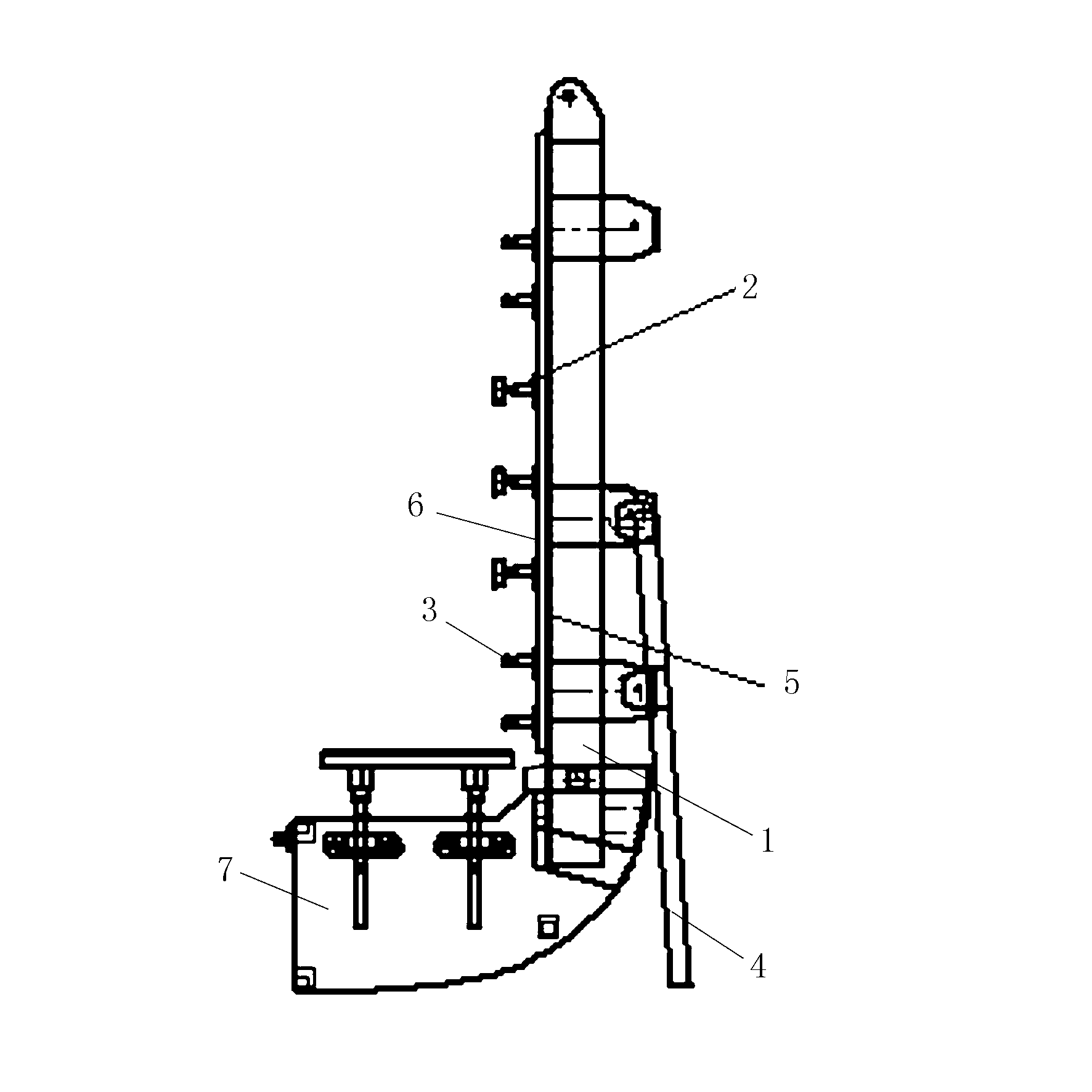

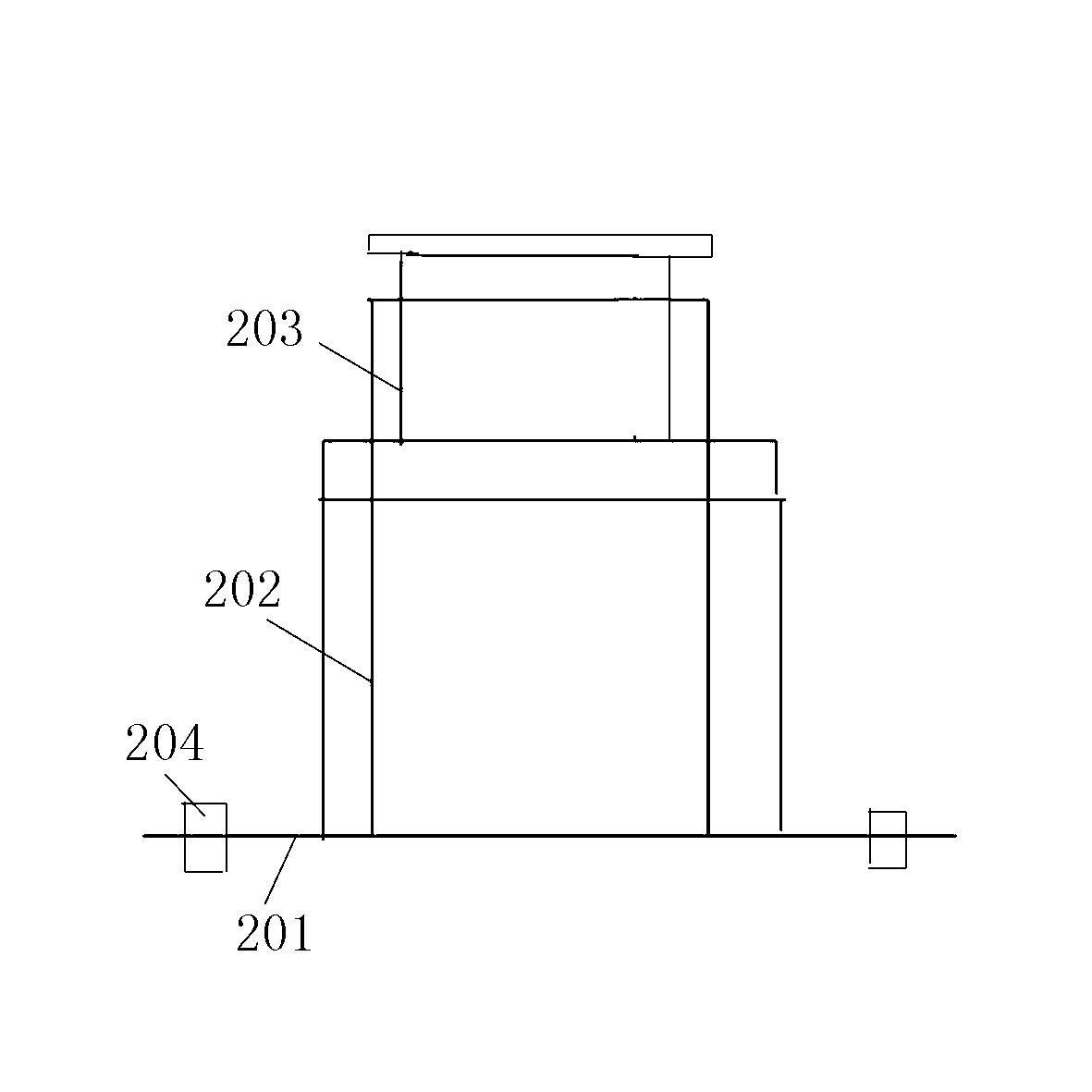

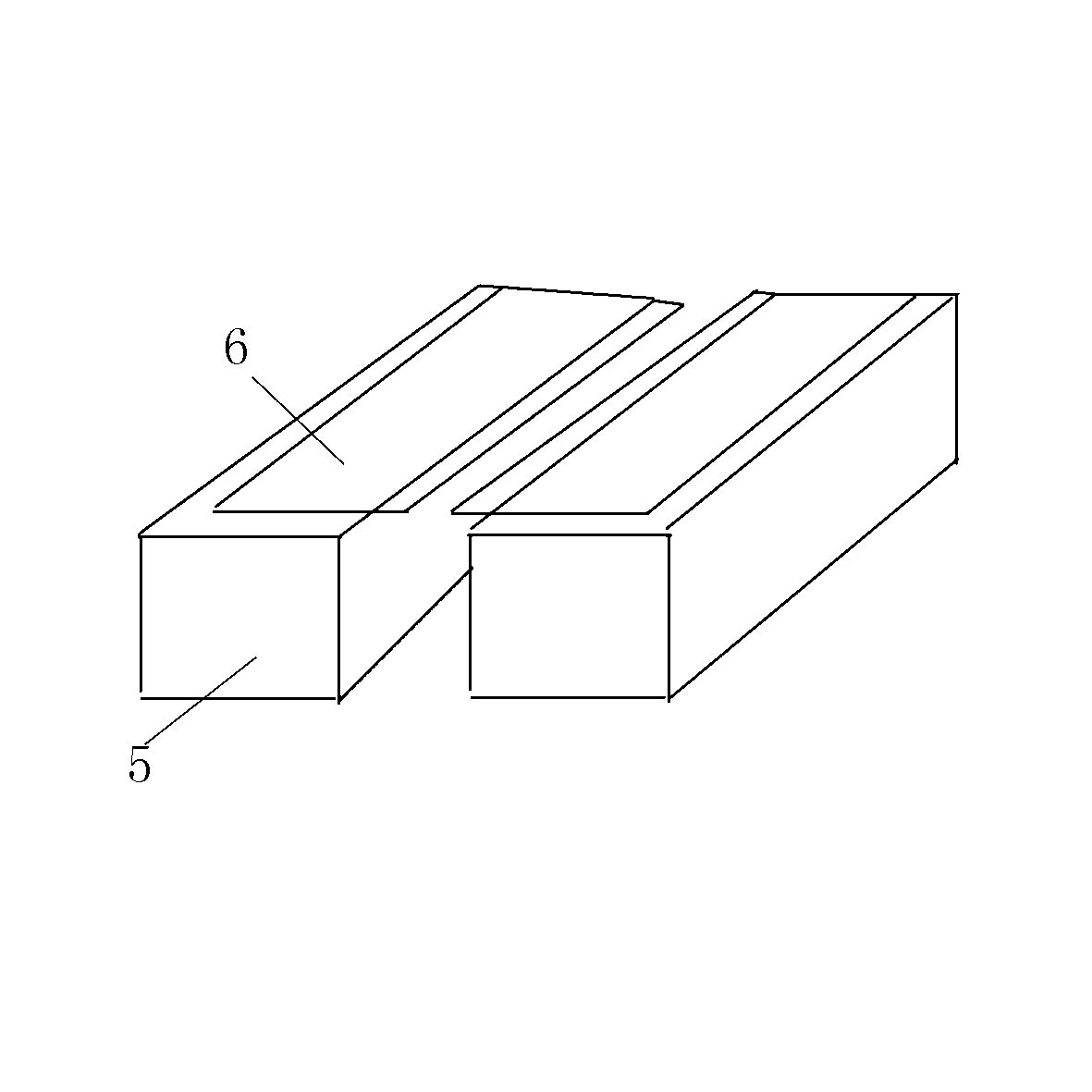

[0022] Such as Figure 1-3 As shown, the lower part of the core turning platform 1 is connected to the support 7, and the supporting frame 4 and the slideway 5 are arranged on the iron core turning platform 1. The outer surface of the slideway 5 is provided with a baffle 6; Set screw 3. The supporter is that the base 201 is provided with a threaded sleeve 202 , and the threaded sleeve 202 is provided with a threaded support column 203 , and the base 201 is fixed on the slideway through a screw rod 204 .

[0023] When the iron core is stacked on the iron core turning platform, the iron core turning platform is placed horizontally, and the supporter rotates and rises and falls through the support column screw when supporting the iron core, so as to realize vertical lifting, and the supporter can slide and shift freely in the slideway; The free-sliding screw can fasten the base of the added support. Two sides of the hexagonal part of the screw are clamped in the slideway, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com