Optical reading heat-mechanical infrared detector structure and manufacturing method thereof

An infrared detector and optical readout technology, applied in optical radiation measurement, scientific instruments, final product manufacturing, etc., can solve problems such as long response time of thermal imaging, failure of pixel energy to be transmitted and lost in time, thermal crosstalk, etc., to achieve The effects of improving temperature response sensitivity, increasing optical fill factor, and accelerating thermal imaging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

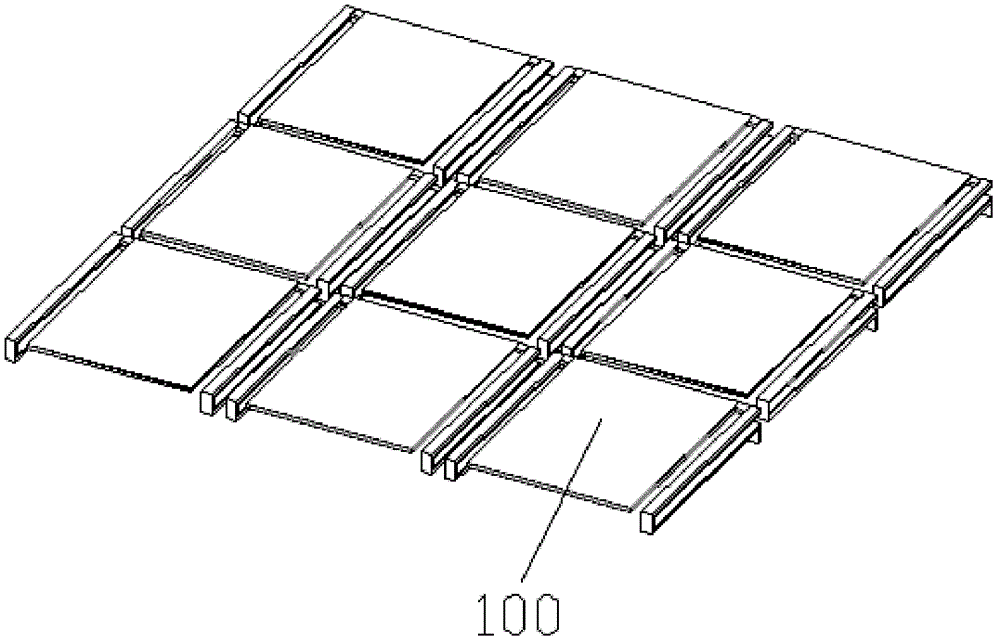

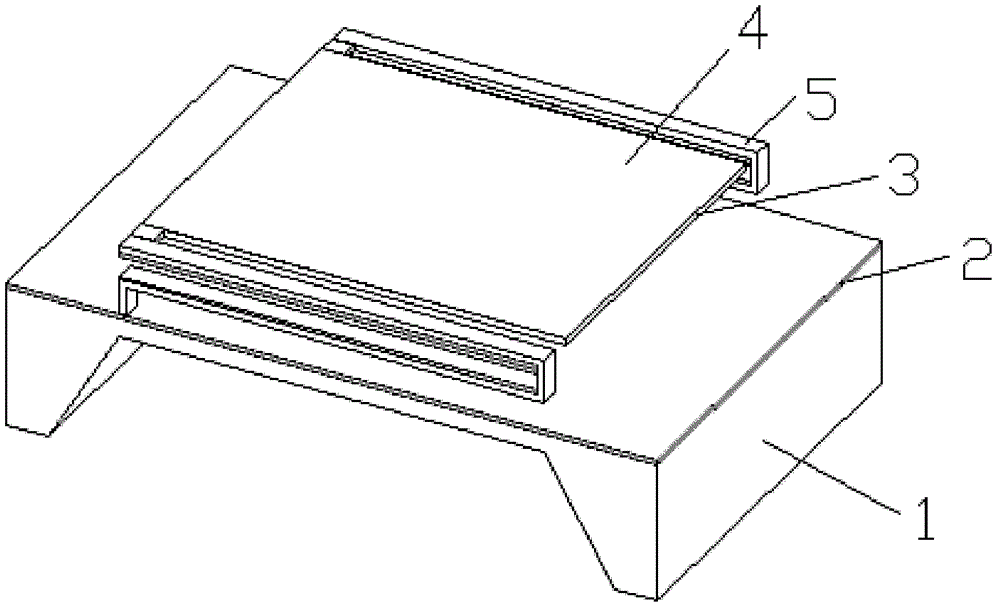

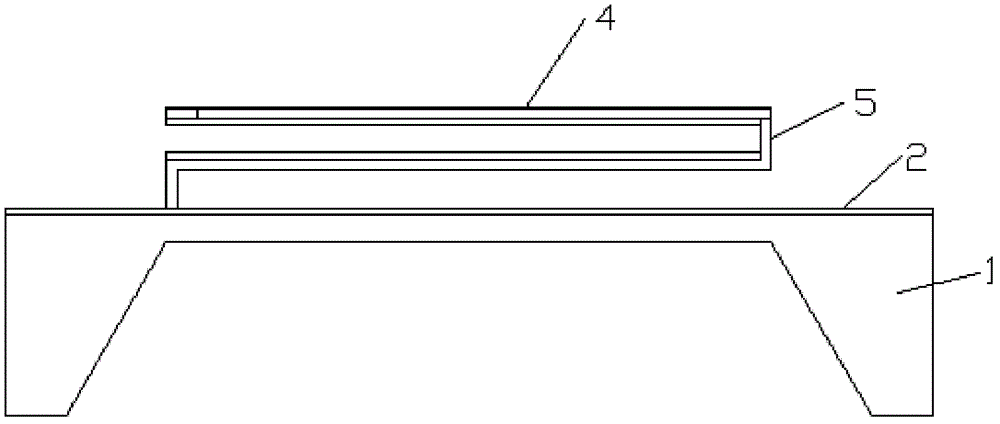

[0049] An optical readout thermal-mechanical infrared detector structure, including several pixel units 100 distributed in an array, each pixel unit includes: a substrate 1, a supporting layer 2, an infrared absorption layer 3, a reflector 4 and The double-material cantilever beam 5, the support layer is located on the upper side of the substrate, and the center of the lower side of the substrate is semi-hollowed out; the space between the infrared absorbing layer is located above the upper side of the supporting layer, and the reflector is located on the upper side of the infrared absorbing layer; There are two material cantilever beams, which are arranged symmetrically on the upper side of the support layer in parallel intervals; each double-material cantilever beam includes upper and lower beams 6 and lower beams 7 arranged in parallel and spaced up and down, and the lower beam is composed of the first non-metallic layer 8 and the second It consists of a metal layer 9, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com