Surface plasmon wave separator based on composite cycle and single cycle

A surface plasmon and recombination period technology, applied in waveguide devices, electrical components, circuits, etc., can solve problems such as unfavorable integration, and achieve the effects of convenient production, low complete loss, and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

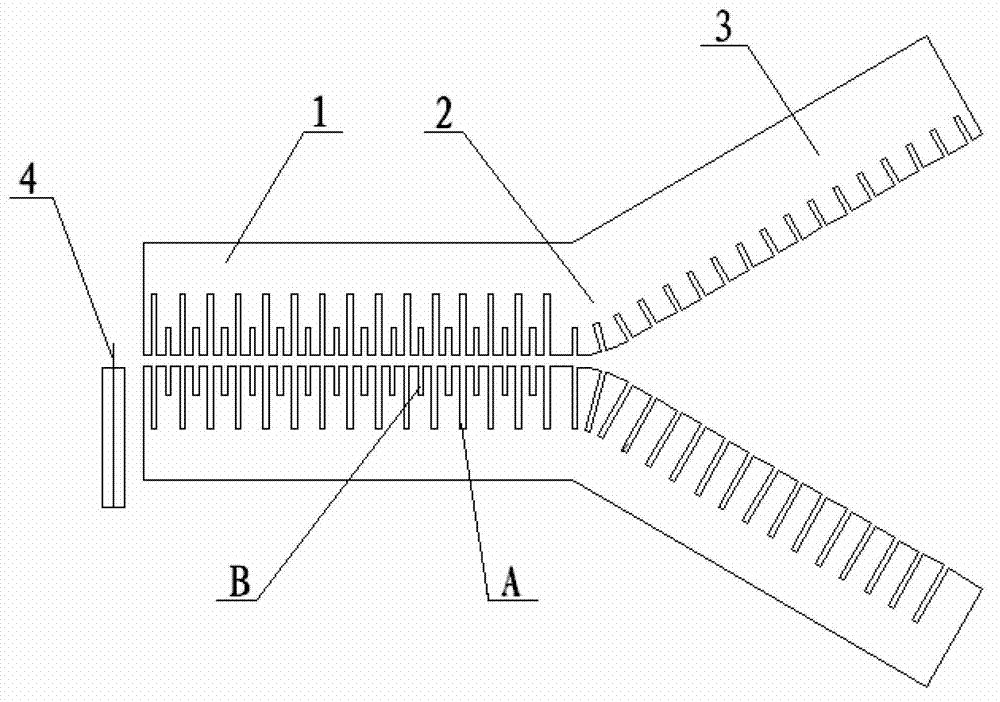

[0017] Such as figure 1 Shown is a surface plasmon wave splitter based on recombination period and single period, including a funnel-shaped grating structure printed on a flexible medium. The grating structure includes two opposite and parallel recombination period straight metal Grating structure 1, two single-period circular arc metal grating structures 2 facing each other, two single-period straight metal grating structures 3 facing each other and forming a certain opening angle, the composite periodic straight metal grating structure 1 and single-period straight metal grating structure The grating structures 3 are tangentially connected by a single-period arc metal grating structure 2; the inner side of the compound-period straight metal grating structure 1 is interlaced with a row of deep grooves A and shallow grooves B, and a group of connected single-period A r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com