Method for preparing high-purity ammonium tetramolybdate mainly by using ammonium molybdate transformation process

A technology of ammonium tetramolybdate and ammonium molybdate, which is applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., to achieve the effects of reducing production costs, wide application range, and reducing waste liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

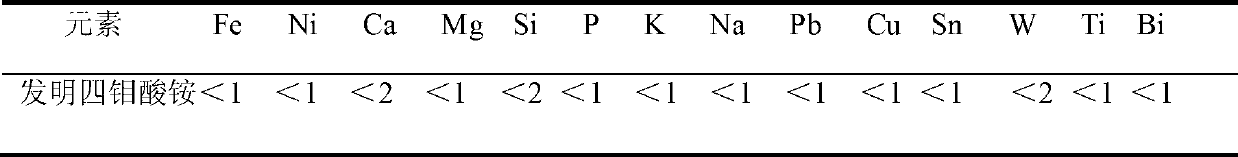

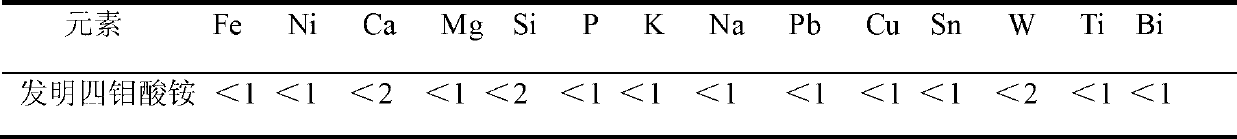

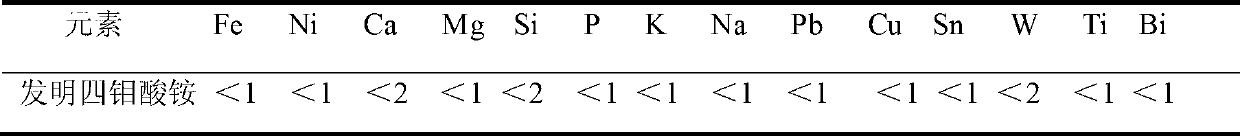

Examples

Embodiment 1

[0026] Weigh 300g of the raw material ammonium tetramolybdate, the quality of W in the raw material ammonium tetramolybdate is 40μg / g, put it into a reactor with a heating mantle and a stirring device filled with 300mL industrial pure water, and gradually add 150mL concentrated Ammonia, mixed solution 1 is obtained after stirring and dissolving completely, and the density of mixed solution 1 is adjusted to 1.36g / cm with pure water 3 , and filtered to remove the solid mechanical impurities contained in the mixed solution 1 to obtain the filtrate 1.

[0027] Under constant stirring at room temperature, the pH value of the filtrate 1 was adjusted to 7.2 with concentrated nitric acid, and 6 g of FeCl 3 The solid powder was added to filtrate 1, stirred at room temperature for 2 h, and filtered to obtain filtrate 2.

[0028] Evaporate and crystallize the filtrate 2, and filter after evaporating 1 / 3 of its total volume to obtain crystals to obtain the filtrate 3 and filter cake 1, w...

Embodiment 2

[0039]Weigh 600g of raw material ammonium tetramolybdate, the quality of W in the raw material ammonium tetramolybdate is 30μg / g, put it into a reactor with heating mantle and stirring device filled with 630mL industrial pure water, add 300mL concentrated Ammonia, mixed solution 1 is obtained after stirring and dissolving completely, and the density of mixed solution 1 is adjusted to 1.38g / cm with pure water 3 , and filtered to remove the solid mechanical impurities contained in the mixed solution 1 to obtain the filtrate 1.

[0040] Under constant stirring at room temperature, the pH value of filtrate 1 was adjusted to 7.5 with concentrated nitric acid, and 14.5g FeCl 3 The solid powder was added to filtrate 1, stirred at room temperature for 2.5 h, and filtered to obtain filtrate 2.

[0041] Evaporate and crystallize the filtrate 2, and filter after evaporating 1 / 3 of its total volume to obtain crystals to obtain the filtrate 3 and filter cake 1, wherein the filter cake 1 i...

Embodiment 3

[0052] Weigh 900g of the raw material ammonium tetramolybdate, the quality of W in the raw material ammonium tetramolybdate is 50μg / g, put it into a reactor with a heating mantle and a stirring device filled with 990mL industrial pure water, and gradually add 450mL of it under stirring at room temperature Concentrated ammonia water, stir and dissolve completely to obtain mixed solution 1, adjust the density of mixed solution 1 to 1.40g / cm with pure water 3 , and filtered to remove the solid mechanical impurities contained in the mixed solution 1 to obtain the filtrate 1.

[0053] Under constant stirring at room temperature, the pH value of filtrate 1 was adjusted to 7.8 with concentrated nitric acid, and 45g FeCl 3 The solid powder was added to filtrate 1, stirred at room temperature for 3 h, and filtered to obtain filtrate 2.

[0054] Evaporate and crystallize the filtrate 2, and filter after evaporating 1 / 3 of its total volume to obtain crystals to obtain the filtrate 3 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com