Gas-liquid interlaced cooling high power density motor

A high power density, liquid cooling technology, applied in the electrical field, can solve problems such as uneven temperature distribution and rotor temperature rise, and achieve the effects of weakening influence, reducing working temperature rise, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in conjunction with accompanying drawings.

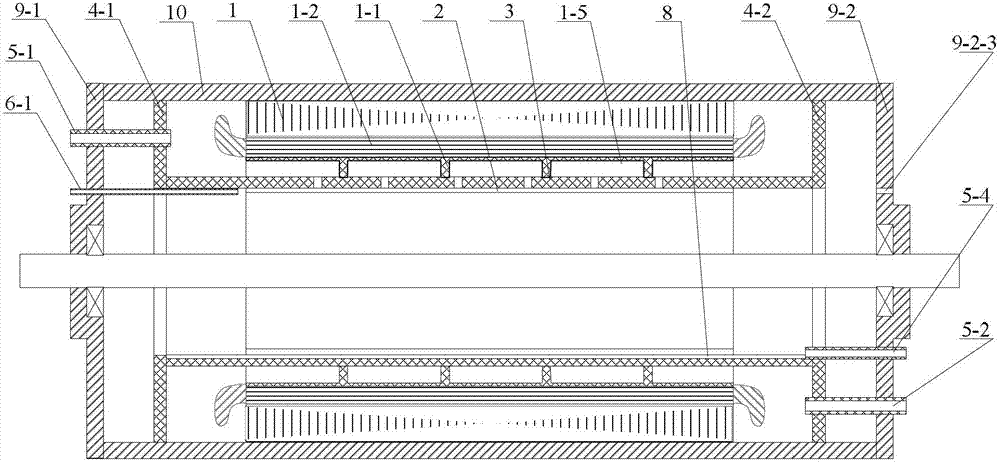

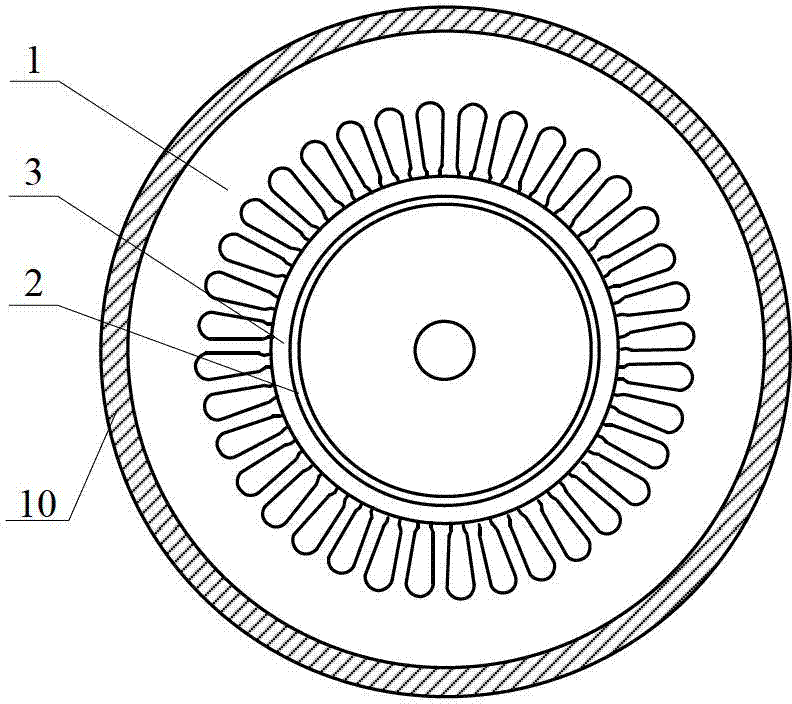

[0043] Air-liquid interweave cooling for high power density motors, such as Figure 1-Figure 9 As shown, the device includes: a stator, a rotor and a cooling system thereof, stator slots 1-1 are evenly distributed along the circumferential direction on the stator core 1, and discharge armature windings 1-2 are embedded in the slots.

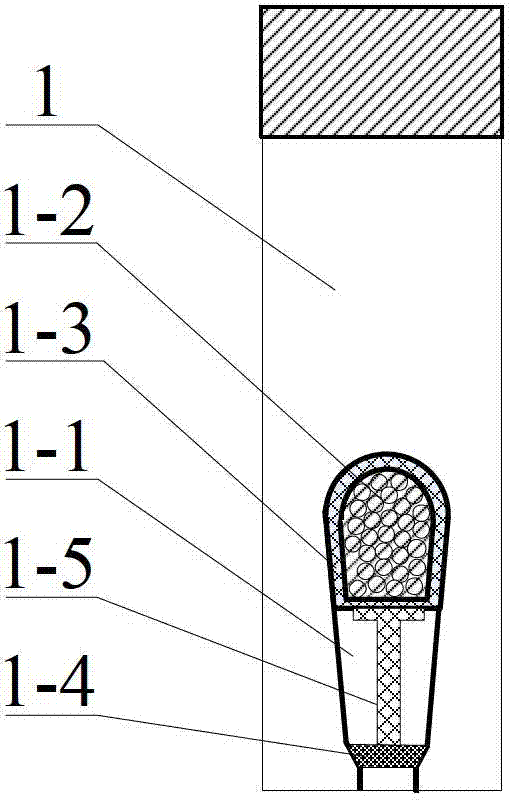

[0044] The cross-sectional area of the armature winding 1-2 is less than 30% to 50% of that of the stator slot 1-1, and its end value or any value in the middle can be selected.

[0045] The armature winding 1-2 is wrapped with an insulating sleeve 1-3.

[0046] The insulating casing 1-3 wrapping the armature winding 1-2 and the stator slot wedge 1-4 are supported by a non-metallic T-shaped bracket 1-5.

[0047] The inner wall surface of both sides of the stator slot 1-1, the inner surface of the stator slot wedge 1-4 and the outer surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com