Buoyant riser of high frame cage-type ecological breeding net cage

An ecological farming and framework technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of slow inflation and drainage, tilting of cages, floating and tipping of cages, etc., to increase strength and stability, and avoid pressure. Poor accumulation, effect of increasing height and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

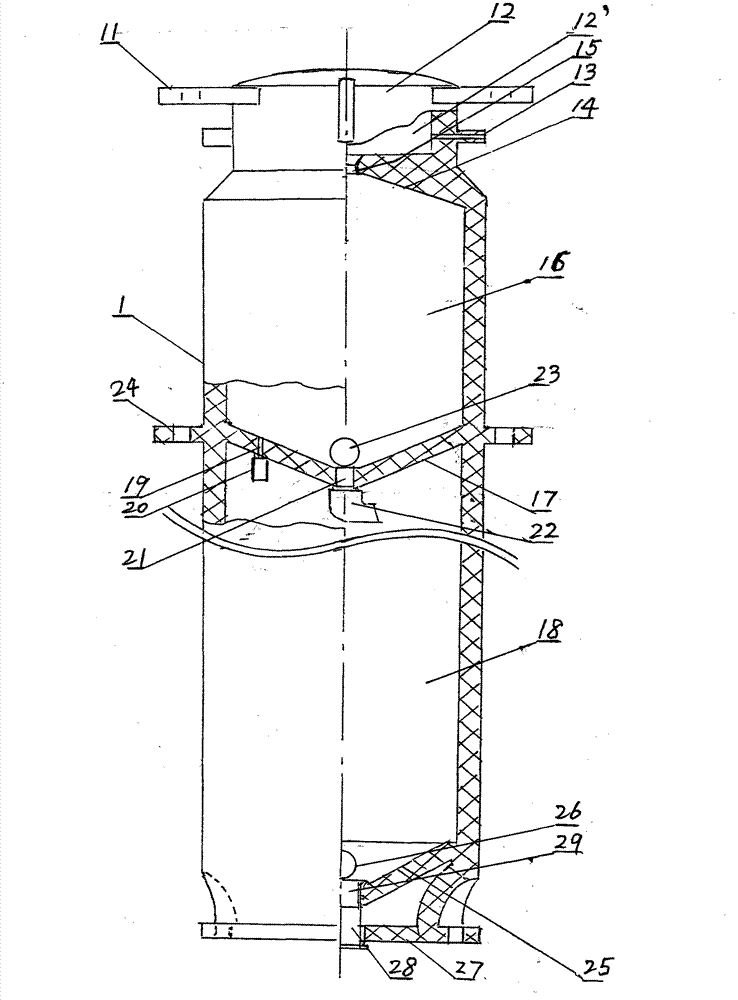

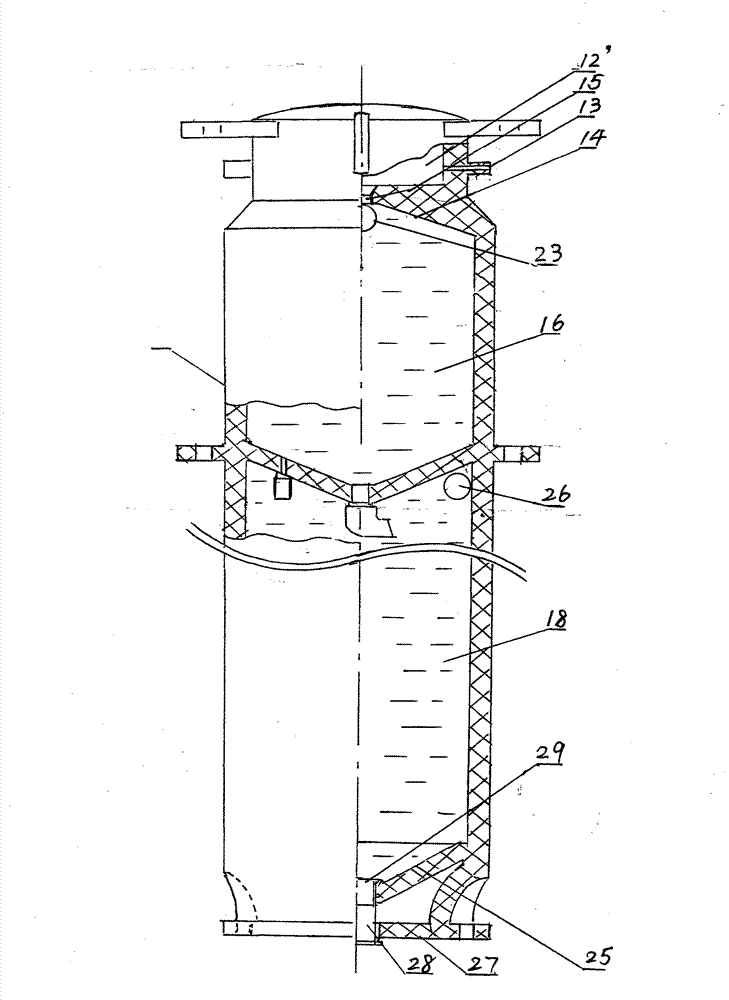

[0017] The first embodiment, as attached figure 2 The main view and attached image 3 Shown in the front view when it is full of water and sinks, it includes a pipe body 1, a pipe cap 12 at the top of the pipe body, a pipe cap connecting ear 11, a pipe cap air chamber 12 ', a pipe cap gas nozzle 13, and a flange 27 at the bottom of the pipe body. The lumen of the pipe body 1 has an arc-shaped cavity top 14 and an arc-shaped cavity bottom 25. The arc-shaped cavity top communicates with the cap air chamber 12' through the cavity top inlet and exhaust ports 15, and the arc-shaped cavity bottom and the bottom of the tube prevent mud and sand from entering. The device 28 communicates with the water inlet and outlet 29 at the bottom of the cavity. The height of the pipe body is 5M. A middle connecting ear 24 is arranged on the outer wall of the middle and upper part at three-fifths of the height of the pipe body to connect the newly added middle horizontal connecting pipe 5 . A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com