Ball mill group monitoring system and monitoring method based on smart cloud computing platform

A computing platform and monitoring system technology, applied in the transmission system, electrical components, grain processing, etc., can solve the problems of high equipment cost, many connections, low reliability, etc., to enhance safety and stability, improve communication path Number, the effect of increasing the speed of the Internet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

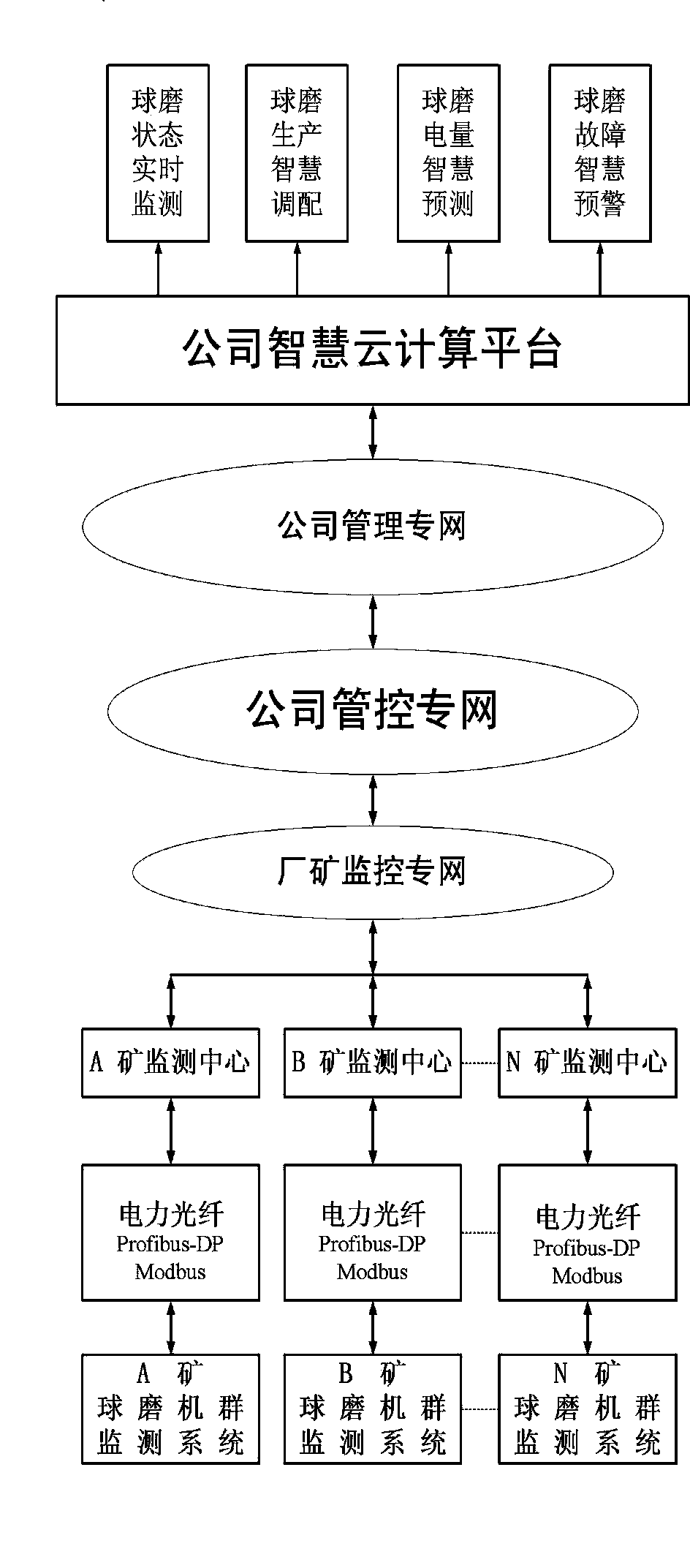

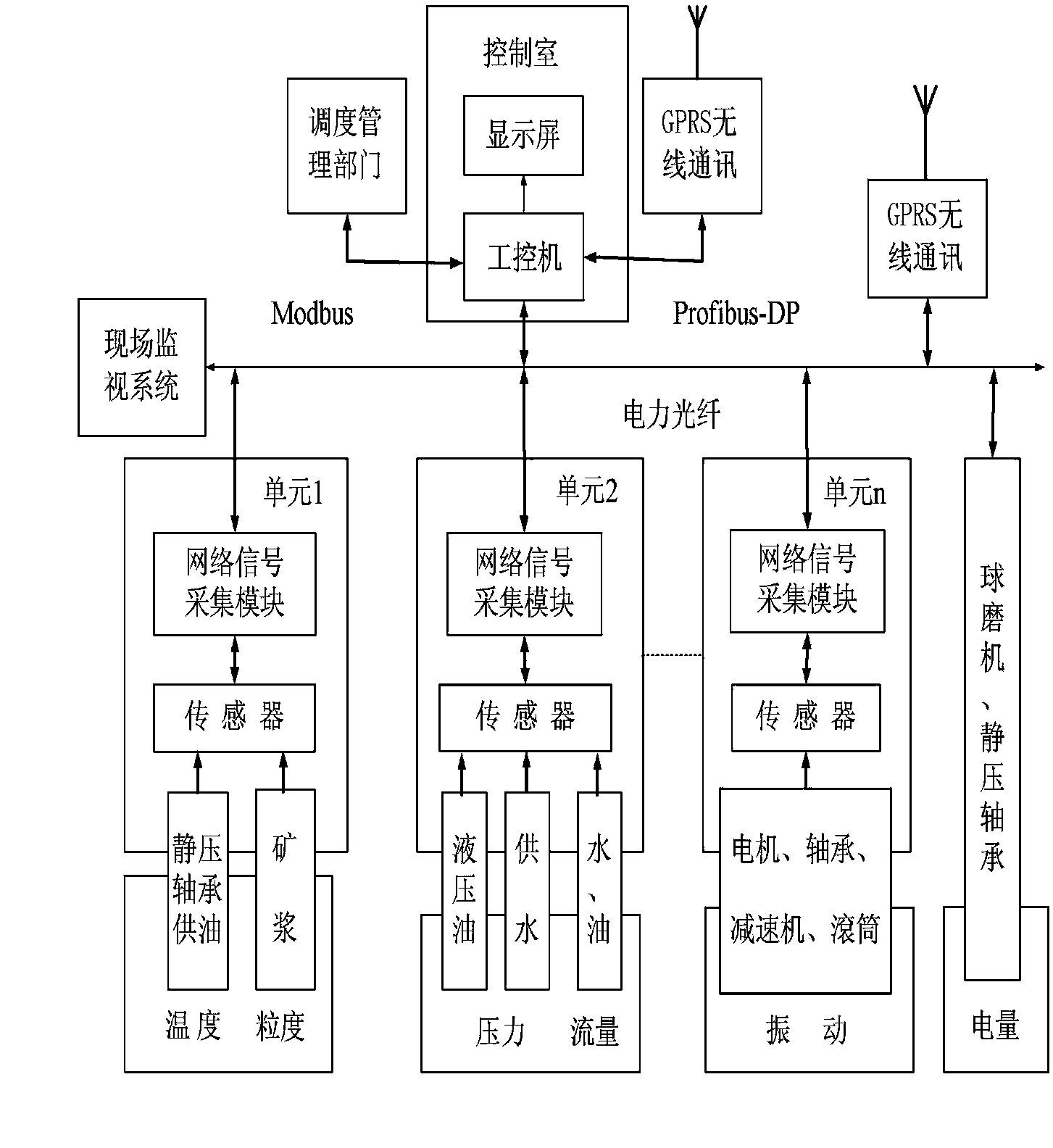

[0048] A large mining enterprise may have multiple mining subsidiaries, each of which has multiple ball mills, or a group of ball mills, and a ball mill system consists of two parts: a ball mill and a hydrostatic bearing. Such as figure 1 As shown, a ball mill group monitoring system based on a smart cloud computing platform of the present invention is characterized by including a monitoring center based on the smart cloud computing platform. The monitoring center is sequentially provided with a system management network and a system management and control network. System monitoring private network, a group of data collection and monitoring modules connected to the said system monitoring private network, such as figure 2 As shown, the data collection and monitoring module includes a data monitoring center, a data transmission device, a ball mill group monit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap