Device and method for cleaning ammonia distillation system

A cleaning device and ammonia distillation technology, which is applied in the field of coking, can solve the problems of poor heat transfer effect, time-consuming and labor-intensive waste of resources, etc. in waste water heat exchangers and waste water coolers, so as to shorten the cleaning time, improve the working environment and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

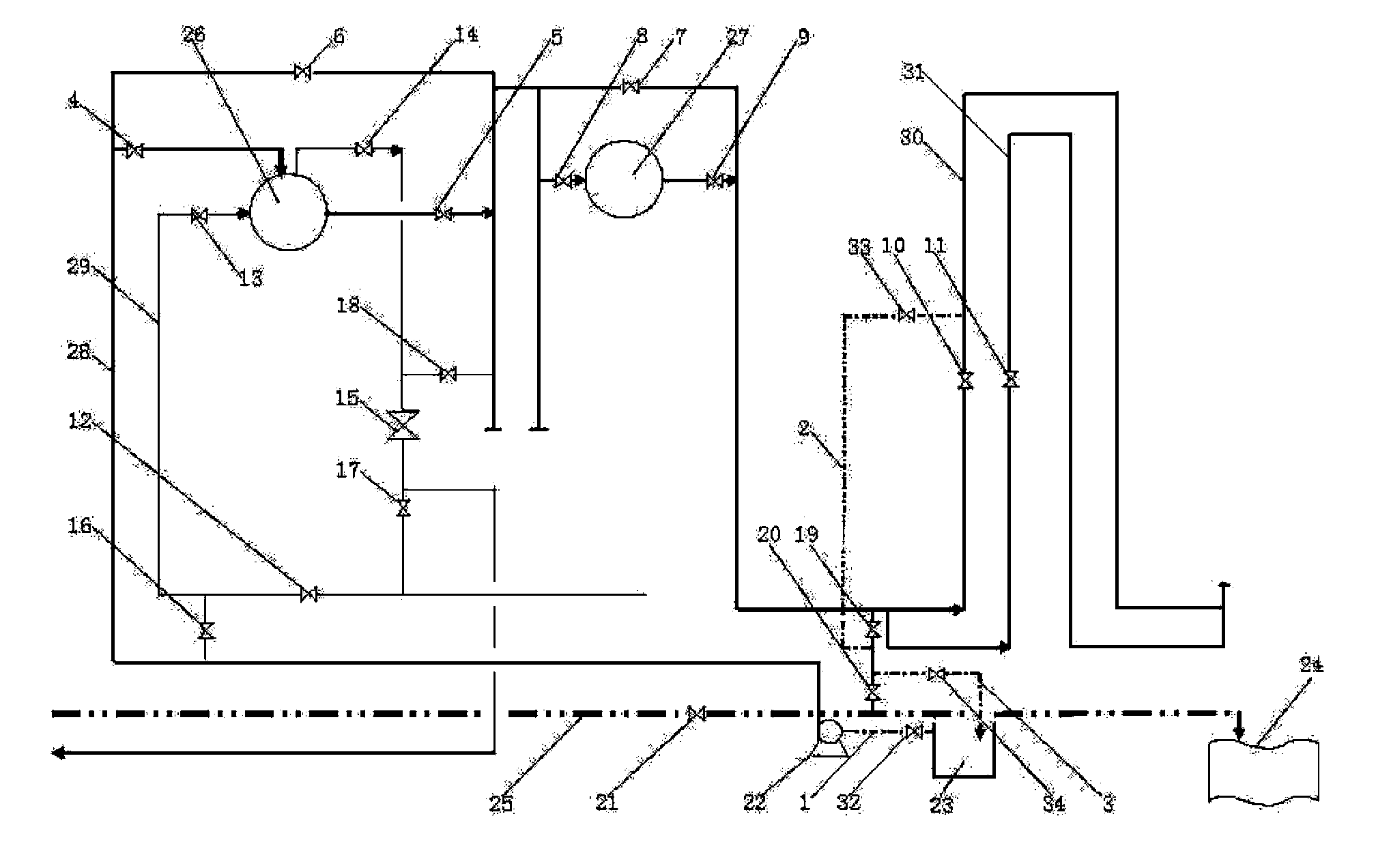

[0020] Depend on figure 1 It can be seen that the ammonia distillation system cleaning device of the present invention is based on the original waste water heat exchanger 26, the waste water cooler 27 and the waste water process pipeline 28 connected thereto, the remaining ammonia water process pipeline 29, the old waste water pipeline 30 and the new waste water pipeline 31, Between the centrifugal pump 22 of the waste water process pipeline 28 and the phenol cyanide auxiliary agent input tank 23, an auxiliary agent pipe 1 and valve nineteen 32 are added; One end of pipe 2 is connected between valve sixteen 19 and valve seventeen 20, and the other end is connected on the old waste water pipe 30 at the rear of valve seven 10; the old waste water pipe 30 between valve sixteen 19 and valve seventeen 20 Connect a return pipe 3 and valve 21 34 on the top, and the other end of the return pipe 3 communicates with the phenol cyanide additive delivery tank 23; connect the slag discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com