Capsule production line

A production line and capsule technology, applied in the coating and other directions, can solve the problems of high air consumption, the rubber sheet is easily loosened from the rubber sheet slot, and the work efficiency, etc., to achieve energy saving, safe and reliable closing and opening, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

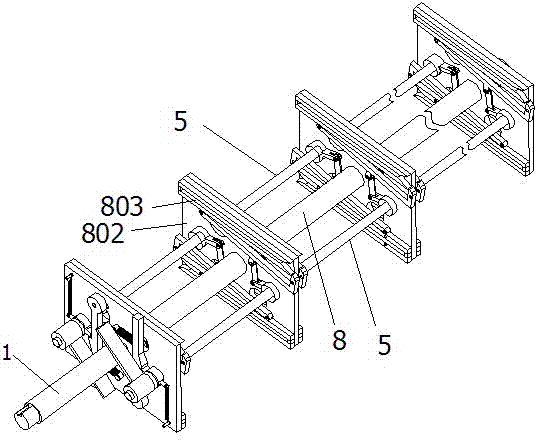

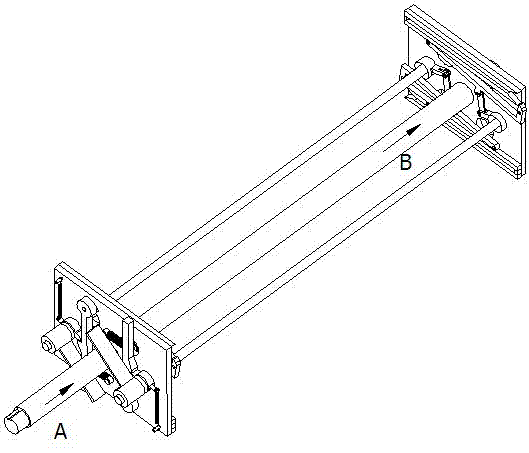

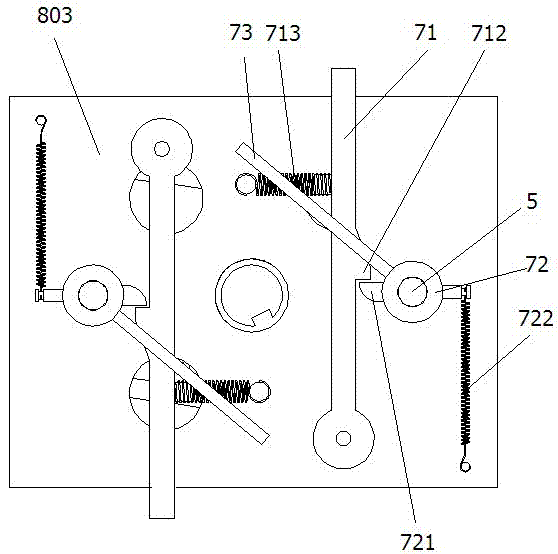

[0030] Such as Figure 1-Figure 5 As shown, a capsule production line of the present invention includes at least two rubber sheet support plates 803, each rubber sheet support plate body is fixedly connected in series by a connecting shaft 8, each support plate body is perpendicular to the connecting shaft 8, and is opposite to each other set up. The supporting plate bodies on both sides are fixedly connected with the rotating shaft rotating shaft 1 . On the surface of each support plate body opposite to the other support plate body, there is a rubber plate slot 802, one end of the rubber plate slot 802 is an open end 807, and the other end is a closed end 808, and the two sides of the rubber plate are provided by corresponding The opening end 807 of the rubber sheet slot 802 on the side is inserted into the rubber sheet slot, and the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com