Silt-preventing function-based sediment overflow ballast tank

An overflow pressure and sediment prevention technology, which is applied in some cabins, ships, and hulls in the hull, can solve the problems of increased hull safety hazards and inconvenient removal, and achieves the goal of reducing work difficulty, maintaining consistency, and reducing safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment approach 64

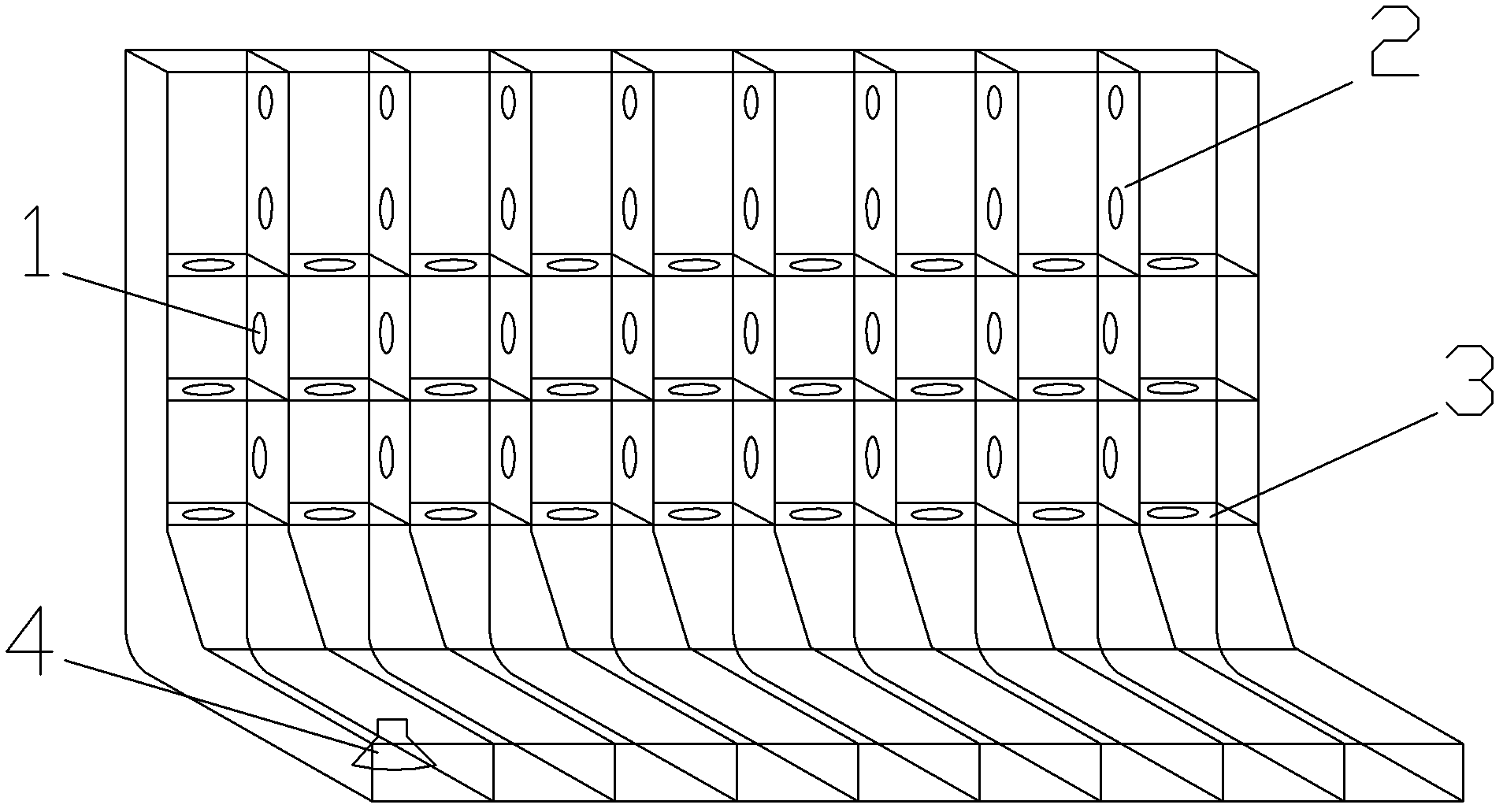

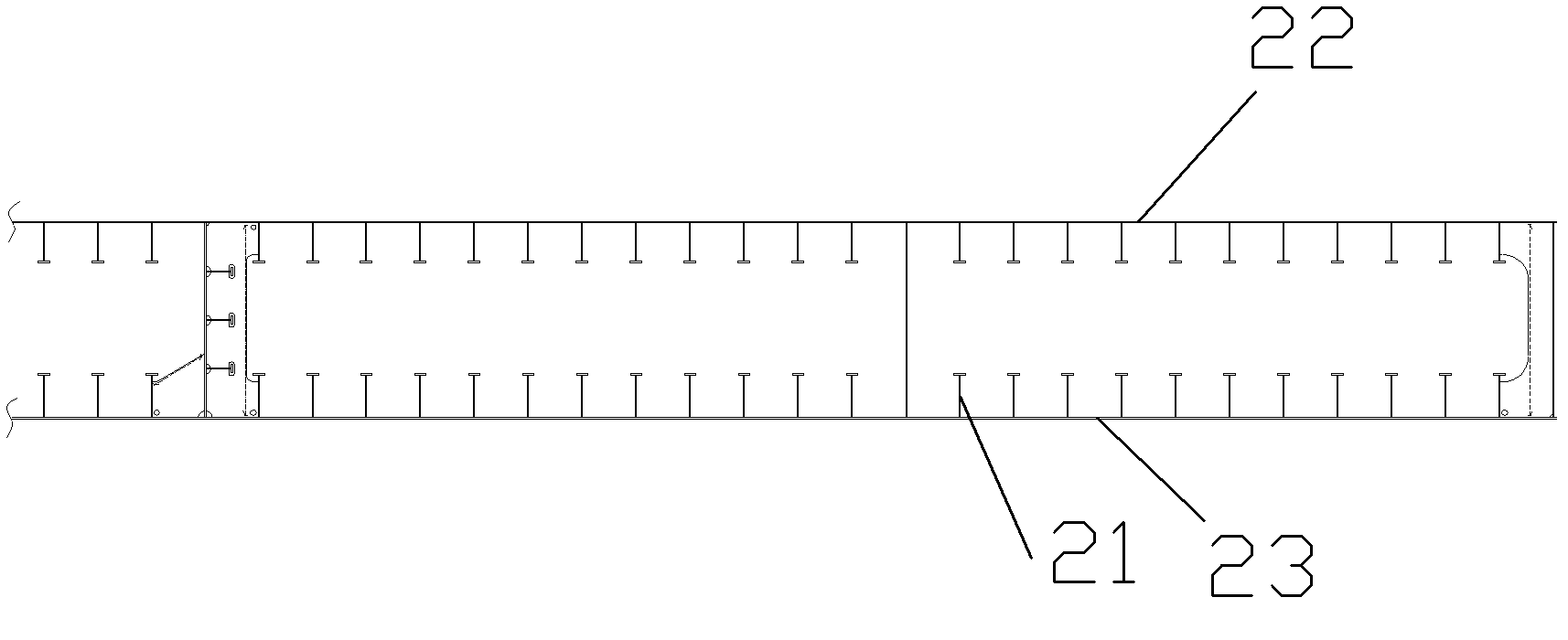

[0030]The present invention is based on experiments, and uses CFD fluid analysis software to carry out a large number of calculations, compare, analyze and demonstrate to obtain the above conclusions. Among them, there are 12 intermediate process schemes and 64 experimental schemes. The invention can deposit 30-40% of the silt in the side sedimentation tank, wherein the silt particles with larger particle diameters that can be deposited in a short time are mainly deposited. The large opening of each rib member 7 of the ballast tank is consistent with the height of the horizontal truss member. When the ballast water is exchanged next time, the ballast water flows along the horizontal truss member, and the side ballast tank can be cleaned automatically. It is easy to operate and saves manpower and material resources. More importantly, the ballast water after the overflow of the side settling tank mainly contains small-sized sediment particles that are not easy to settle in a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com