Spodumene roasting transformation method

A spodumene and roasting technology, which is applied in the direction of aluminum silicate, silicate, energy input, etc., can solve the problems of low production capacity and waste of resources, and achieve the effects of increasing production, reducing costs, and increasing application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Pretreat domestic spodumene raw ore, that is, dry it in a hammer dryer to a water content of 3%, and then grind it until the spodumene fineness is below 100 mesh; among them, domestic spodumene The chemical composition of Shiyuan ore is: Li 2 O 5.0, Fe 2 o 3 2.4, K 2 O 0.21, Na 2 O 0.57, Al 2 o 3 22.7, SiO2 2 64.0, CaO 1.2, MnO 0.2 and water 13.0.

[0022] (2) Then place it in the cyclone preheating system for suspension preheating, the steps of suspension preheating are:

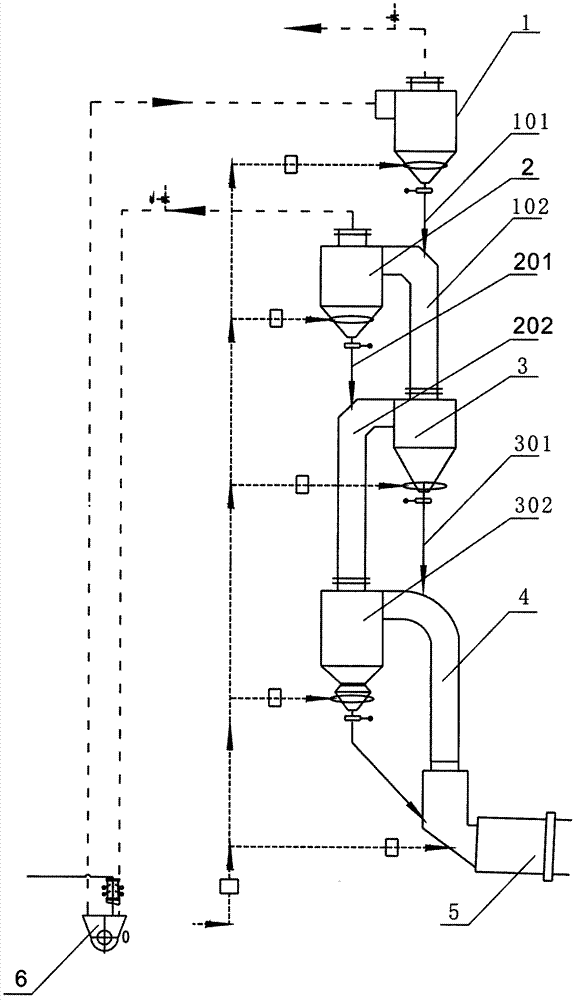

[0023] i. The pretreated spodumene is transported from the hammer dryer 6 to the primary cyclone 1, and after being collected by the primary cyclone 1, it is transported by the primary material pipeline 101 to the primary hot air pipeline 102 for suspension pretreatment heat, and then the material is brought to the secondary cyclone 2 by the hot blast in the hot blast duct;

[0024] Ⅱ. The secondary cyclone 2 collects the material and transports it from the secondary material pipeline...

Embodiment 2

[0029] (1) Pretreat the Australian lithium concentrate, that is, dry it in the hammer dryer 6 to a water content of 1%, and then grind it until the spodumene fineness is below 100 mesh; wherein, its chemical composition For: Li 2 O 6.0, Fe 2 o 3 0.50,K 2 O 0.30, Na 2 O 0.25, Al 2 o 3 22.0, SiO 2 68.0, CaO 0.25, MnO 0.10, TiO 2 0.10,P 2 o 5 0.20 and water 6.0.

[0030] (2) Then place it in the cyclone preheating system for suspension preheating, the steps of suspension preheating are:

[0031] i. The pretreated spodumene is transported from the hammer dryer 6 to the primary cyclone 1, and after being collected by the primary cyclone 1, it is transported by the primary material pipeline 101 to the primary hot air pipeline 102 for suspension pretreatment heat, and then the material is brought to the secondary cyclone 2 by the hot blast in the hot blast duct;

[0032] Ⅱ. The secondary cyclone 2 collects the material and transports it from the secondary material pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com