Improved rubber support

A technology of rubber bearings and lead cores, applied to springs made of plastic materials, low internal friction springs, springs/shock absorbers, etc., can solve problems such as high rigidity, affecting the isolation effect of small earthquakes, and large damping. Achieve the effects of easy production, improving the force characteristics of rubber, and improving the performance of shock isolation and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

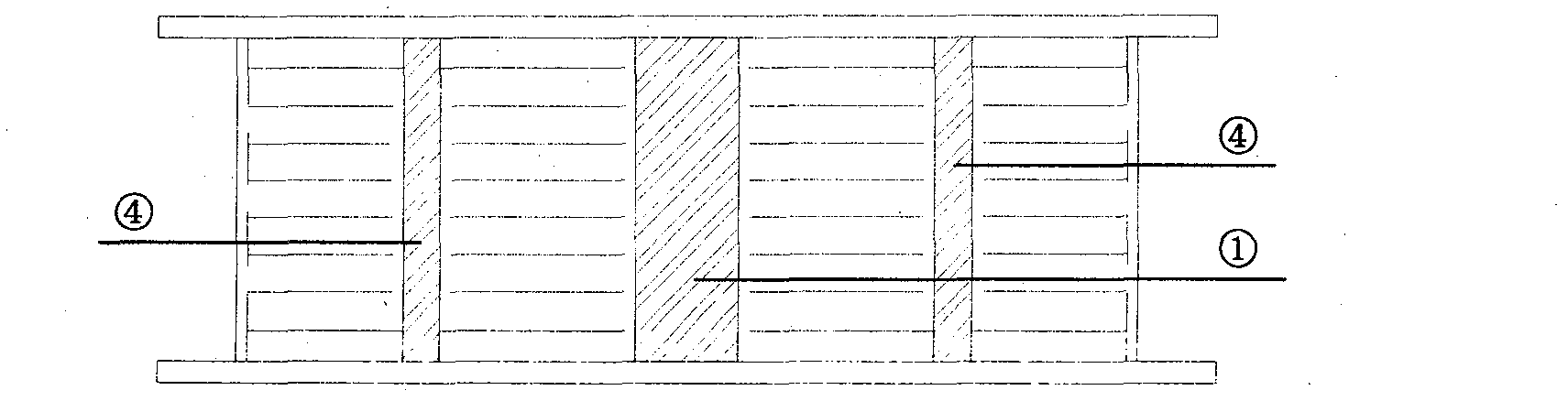

[0021] The steel plate and rubber layer of the support can be processed according to the conventional method. The vulcanization and fixing of the support can be carried out according to the conventional production method. The fixing during production can be fixed from one end or both ends, and the lead core can be pressed in from one end or both ends. .

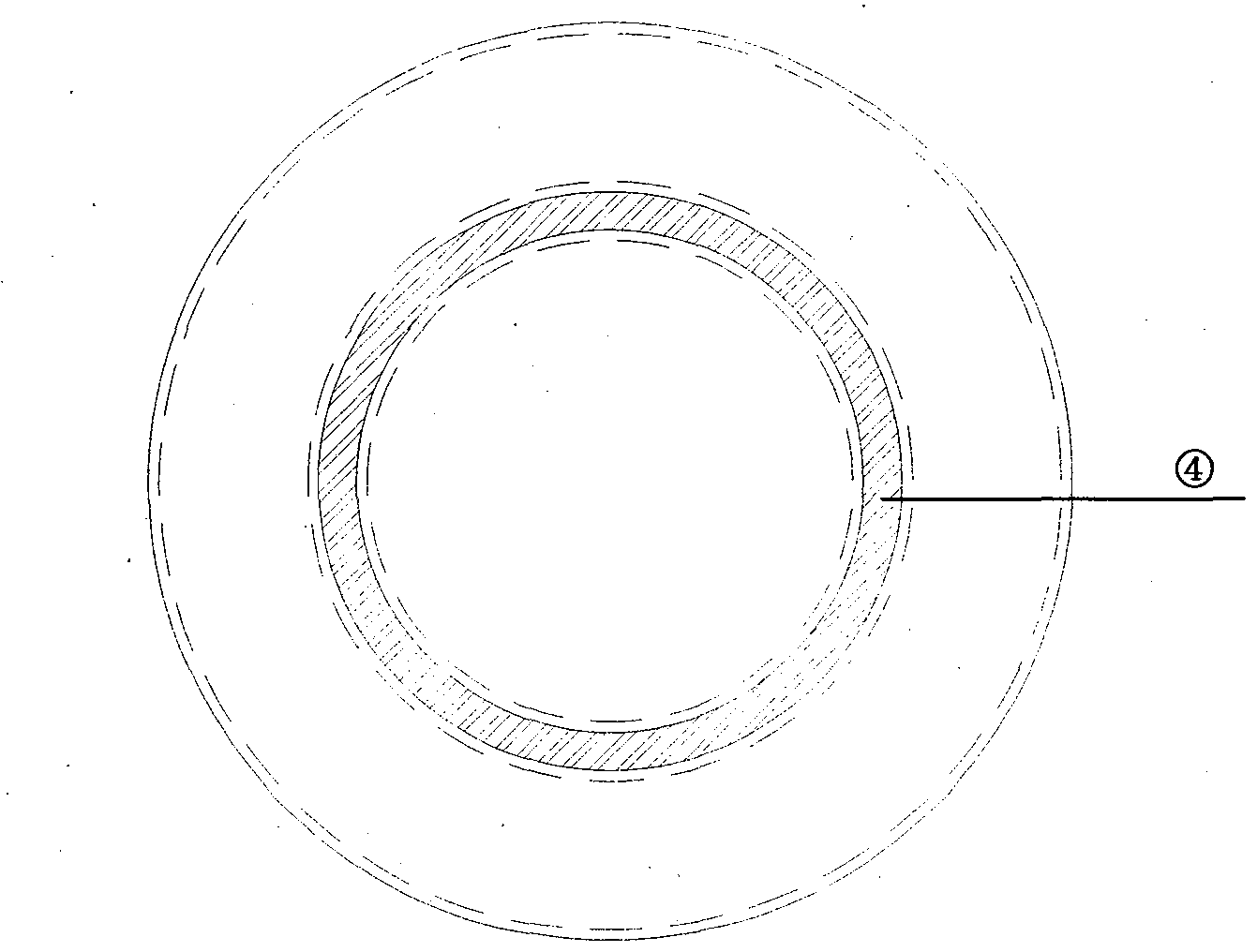

[0022] The ring-shaped lead-core rubber bearing can be processed and produced separately from the inner rubber bearing part and the outer rubber bearing part, then assembled, and then pressed into the lead core; it can also be processed and produced in one piece at the same time, and then pressed into the lead core.

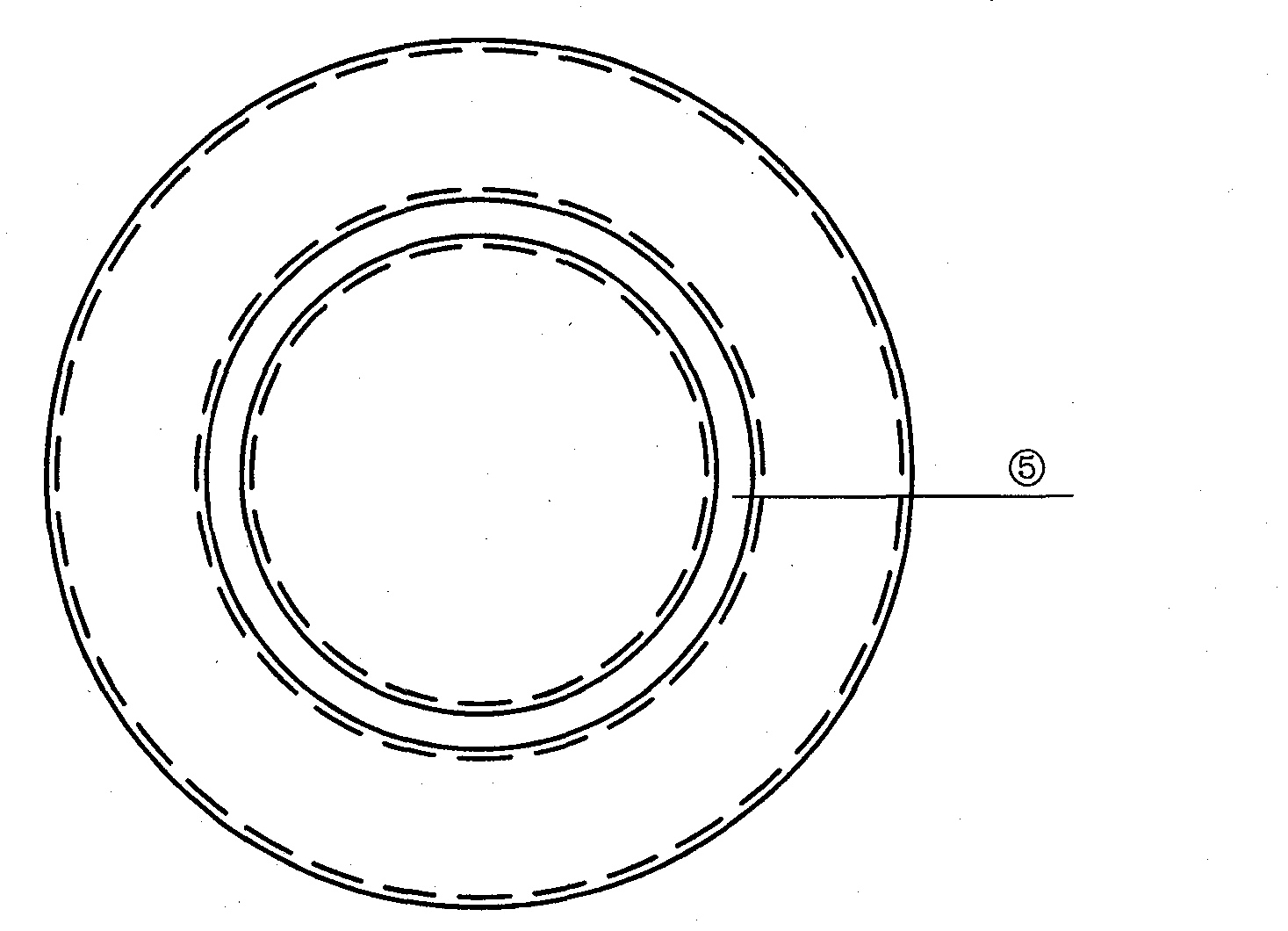

[0023] The lead-free ring center hole rubber bearing can be processed and produced separately from the inner rubber bearing part and the outer rubber bearing part, and then assembled; it can also be processed and produced at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com