Movable engineering machine and counter weight mechanism

A kind of construction machinery and mobile technology, which is applied in the direction of cranes, infrastructure engineering, counterweight, etc., can solve the problem of high cost of transition operation, achieve the effect of reducing the cost of transition operation, ensuring reliability and stability, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0033] In this document, the liquid may be a liquid with an appropriate density; based on the cost of the liquid and the convenience of acquisition, the liquid is preferably water.

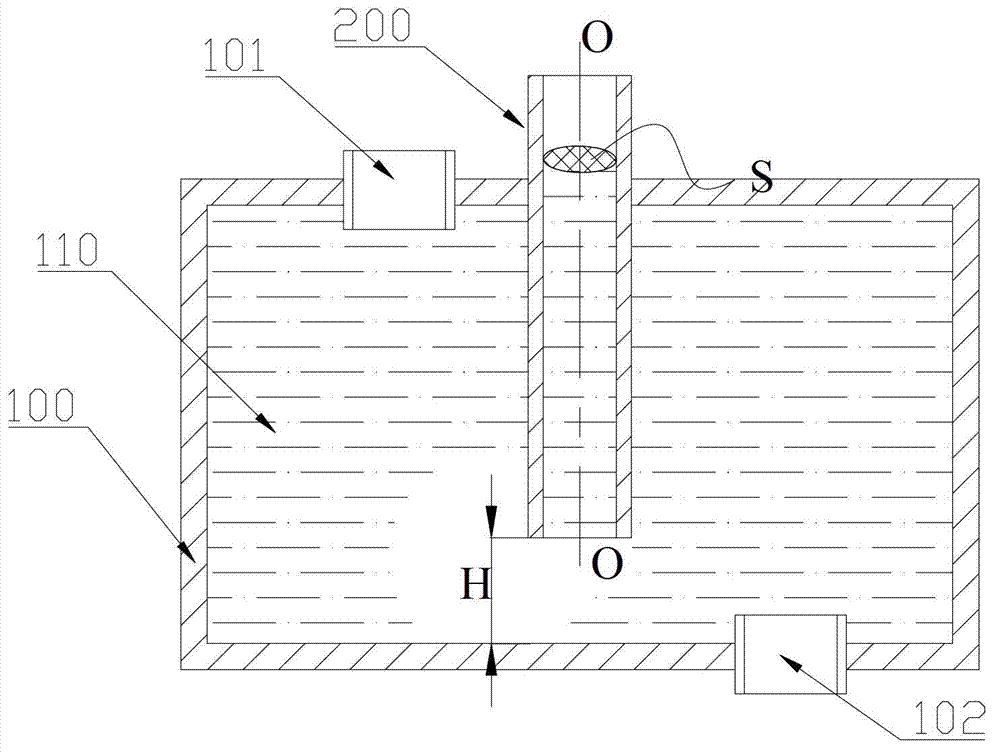

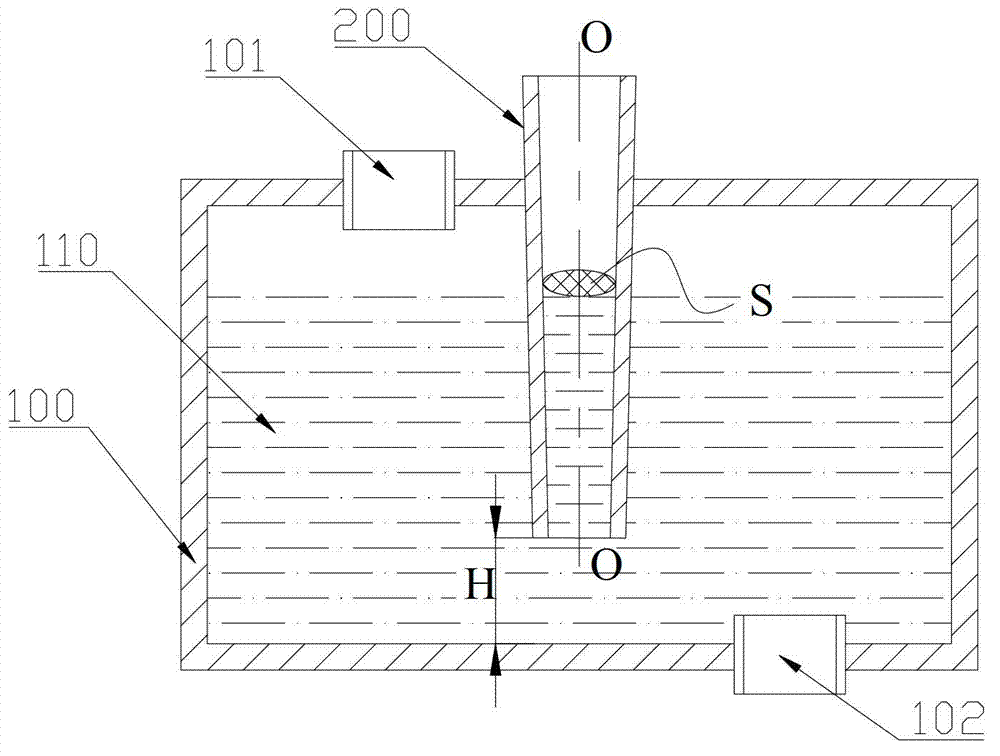

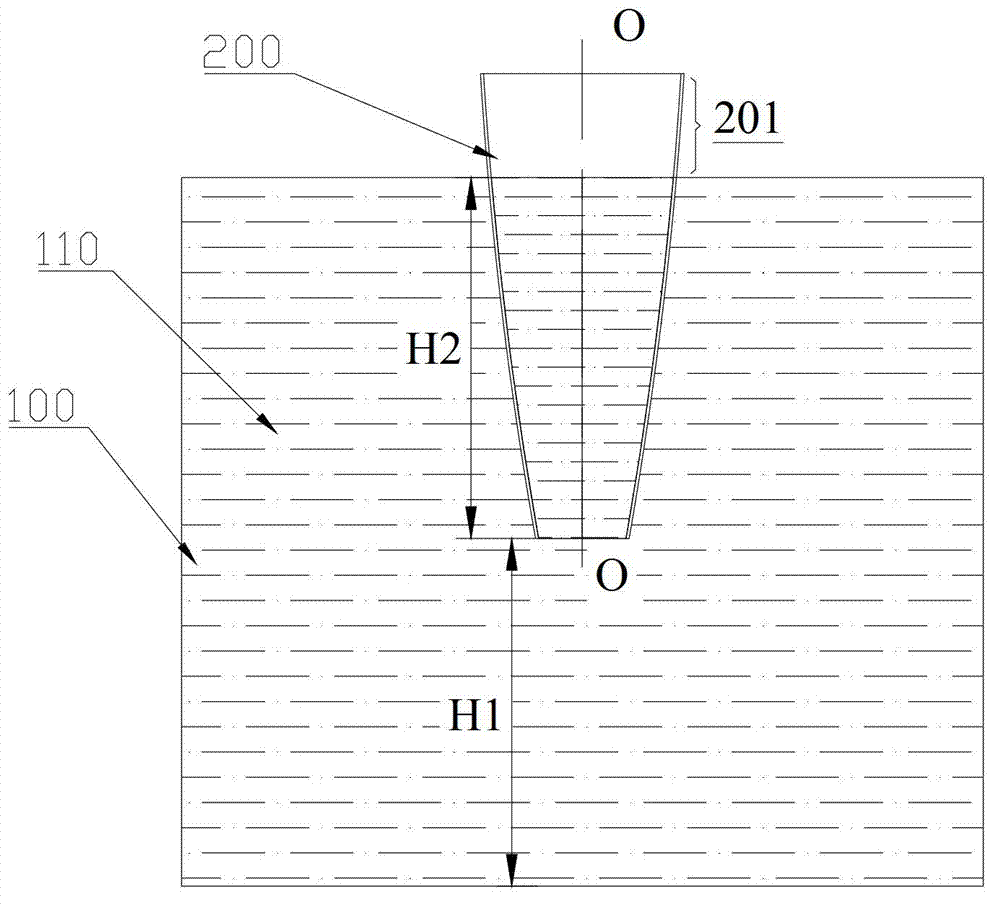

[0034] Please refer to figure 1 , figure 1 It is a schematic diagram of the principle structure of the counterweight mechanism provided by the first embodiment of the present invention. The counterweight mechanism provided by this embodiment is used for mobile engineering machinery. The counterweight mechanism includes a box body 100 and a draft tube 200 fixed relatively to the box body 100 .

[0035] The tank 100 forms a liquid cavity 110 for containing liquid. The volume and shape of the liquid chamber 110 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com