High-precision flattening and shock absorbing mechanism for thin steel sheet

A thin steel, high-precision technology, used in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of plastic deformation of thin steel sheets, high probability of steel sheet vibration, and reduced system speed. Vibration, good vacuuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

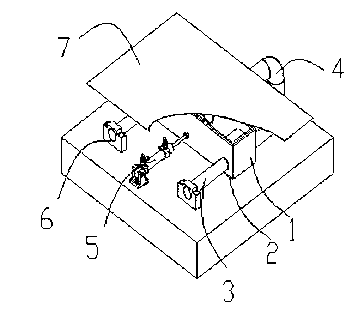

[0024] refer to figure 1 , a high-precision thin steel sheet Zhangping shock absorbing mechanism, including a support arranged under the thin steel sheet, the support adopts Zhangping support 1, Zhangping support 1 is in the shape of a long strip, Zhangping support 1 The top has grooves. One end of the Zhangping support 1 is connected to the horizontal movement mechanism 5, and the other end of the Zhangping support 1 is provided with a dust suction pipe 4, one end of the dust suction pipe 4 communicates with the groove, and the other end of the dust suction pipe 4 is connected to a vacuum cleaner. The grooves are elongated. In order to better absorb the thin steel sheet, make the thin steel sheet as flat as possible. When the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com