Thin steel sheet automatic loading and unloading device

An automatic loading and unloading, thin steel sheet technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of unsatisfactory laser processing technology, low production efficiency, and uneven thin steel sheet, and achieve long-term work stability Reliable, increase efficiency, eliminate large wave deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

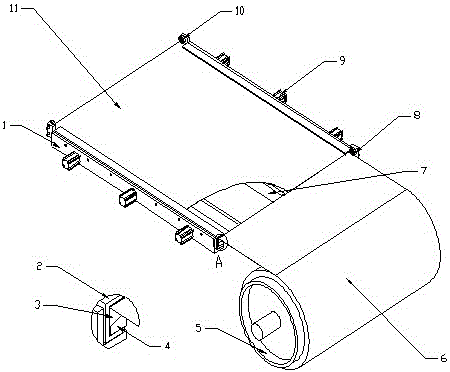

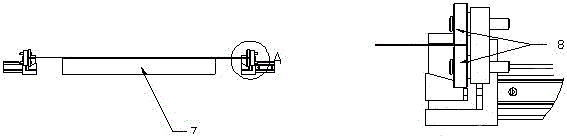

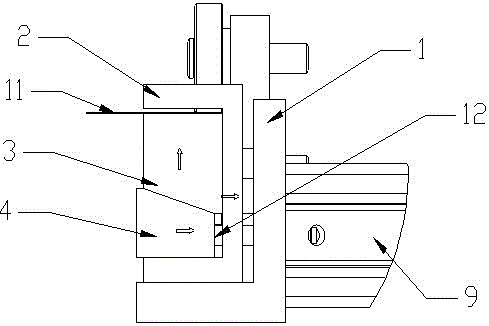

[0023] Such as Figure 1-3 As shown, a thin steel sheet automatic loading and unloading device includes left and right grippers, the structures of the left and right grippers are the same, and the grippers include a T-shaped base 1, a U-shaped clamping frame 2, an upper top pressing bar 3, Wedge-shaped tension bar 4, cylinder 9 and connecting rod 12; U-shaped clamping frame 2 is arranged on T-shaped base 1, U-shaped clamping frame 2 can move to the right, and upper The top compression strip 3 and the wedge-shaped tension strip 4, the upper top compression strip 3 and the upper end of the U-shaped clamping frame 2 form a slot for accommodating the thin steel sheet 11, and the right end of the T-shaped base 1 is provided with a cylinder 9, Connecting rod 12 connects cylinder 9 and wedge-shaped tension bar 4. The right end of the T-shaped base 1 is provided with three cylinders 9, and the cylinders 9 are evenly distributed on the right end of the T-shaped base 1. Two feeding ro...

Embodiment 2

[0027] An automatic loading and unloading device for thin steel sheets, including left and right grippers, which have the same structure, and the grippers include T-shaped base 1, U-shaped clamping frame 2, upper top pressing bar 3, wedge-shaped tensioning Bar 4, cylinder 9 and connecting rod 12; a U-shaped clamping frame 2 is arranged on the T-shaped base 1, and the U-shaped clamping frame 2 can move to the right; Bar 3 and wedge-shaped tension bar 4, the top pressing bar 3 and the upper end of the U-shaped clamping frame 2 form a slot for accommodating the thin steel sheet 11, and the right end of the T-shaped base 1 is provided with a cylinder 9 and a connecting rod 12 Connect cylinder 9 and wedge tension bar 4. The right end of the T-shaped base 1 is provided with four cylinders 9, and the cylinders 9 are evenly distributed on the right end of the T-shaped base 1. Two feeding rollers 8 are arranged at the front end of the holder for driving the thin steel sheet 11 into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com