Positioning device of welding fixture for rear main pipe

A welding tool and positioning device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of large product error, high defective rate, inaccurate and reliable positioning, etc., and achieve good reliability and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiments.

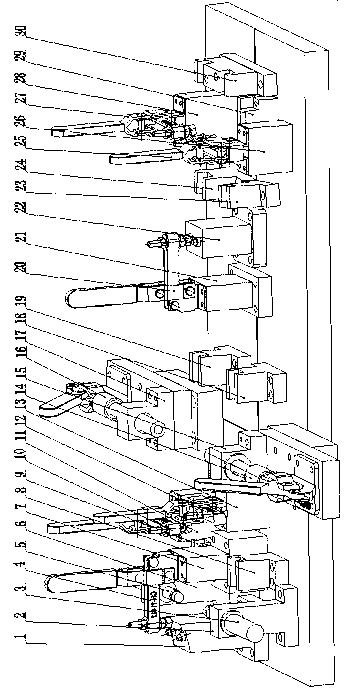

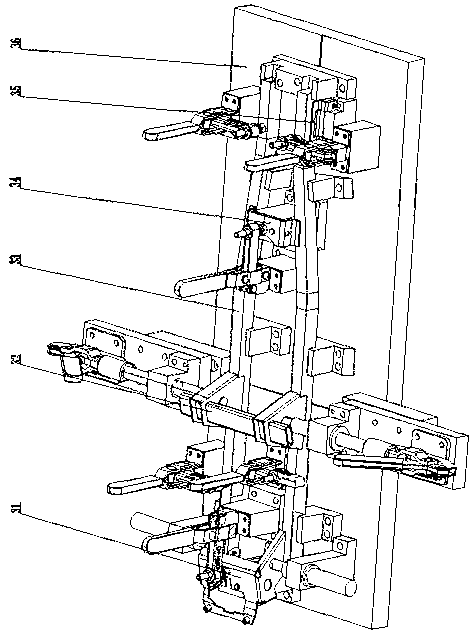

[0021] Such as figure 1 and figure 2 As shown, a rear main pipe welding tool positioning device includes a tooling assembly base plate 36, and seven rear main tube limiting seats ( The rear supervisor limit seat includes: the first rear supervisor limit seat 8, the second rear supervisor limit seat 9, the first middle limit seat 18, the second middle limit seat 19, the third rear supervisor limit seat 23 , the fourth rear supervisor limit seat 24, the front limit seat 30), and the first quick clamp fixing seat 11, the second quick clamp fixing seat 13, the third quick clamp fixing seat 11 are also installed on the bottom plate 36 of the tooling assembly. Clip holder 26 and the fourth quick clamp holder 28 four quick clamp holders, the first quick press clamp 10, the second quick press clamp 12, the third quick press clamp are installed successively on these fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com