In-place measuring device and measuring method for separated electricity jumpiness of main shaft rotation error

A technology of rotary error and measuring device, which is applied in the direction of measuring device, electric device, optical device, etc., can solve the problems of long measurement period, cumbersome operation of transposition method, difficult installation and adjustment, etc., and achieve efficient on-site measurement, high Flexible and versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

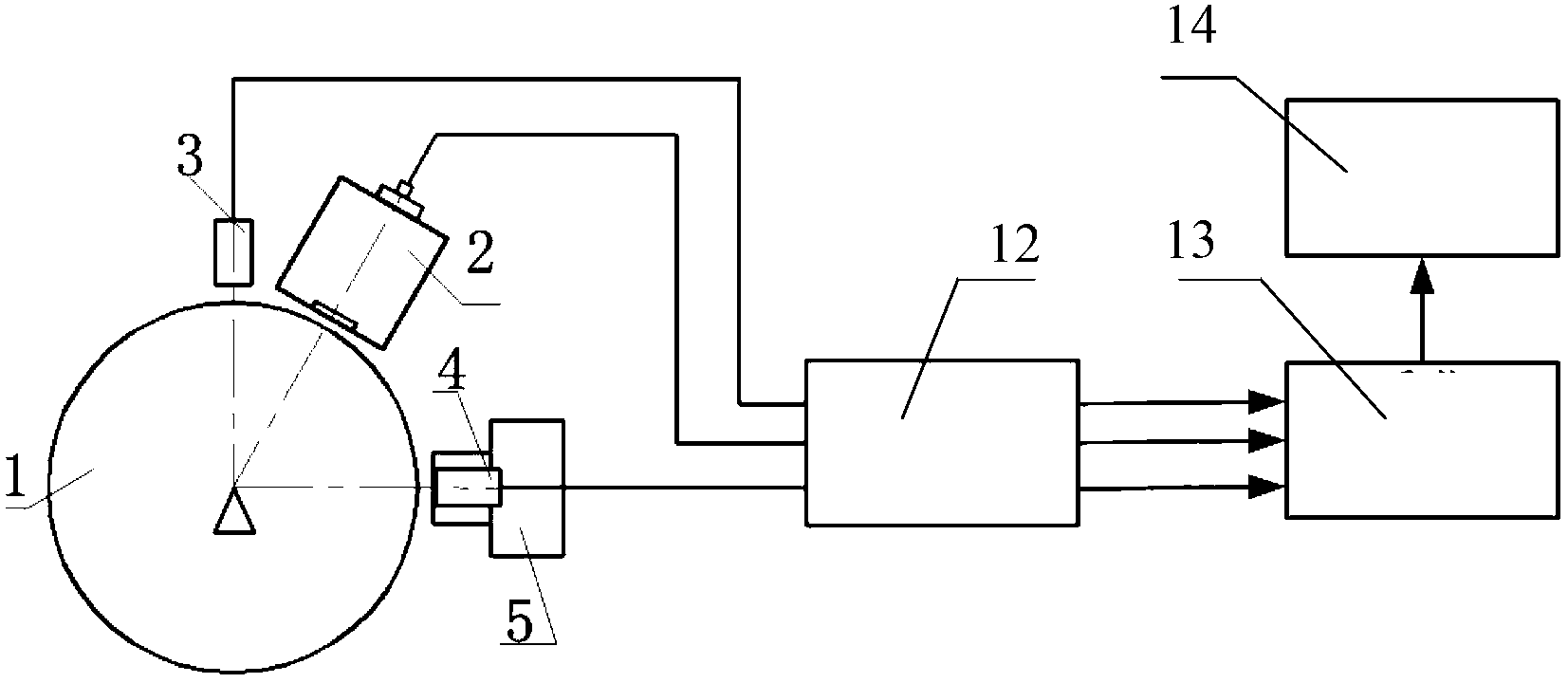

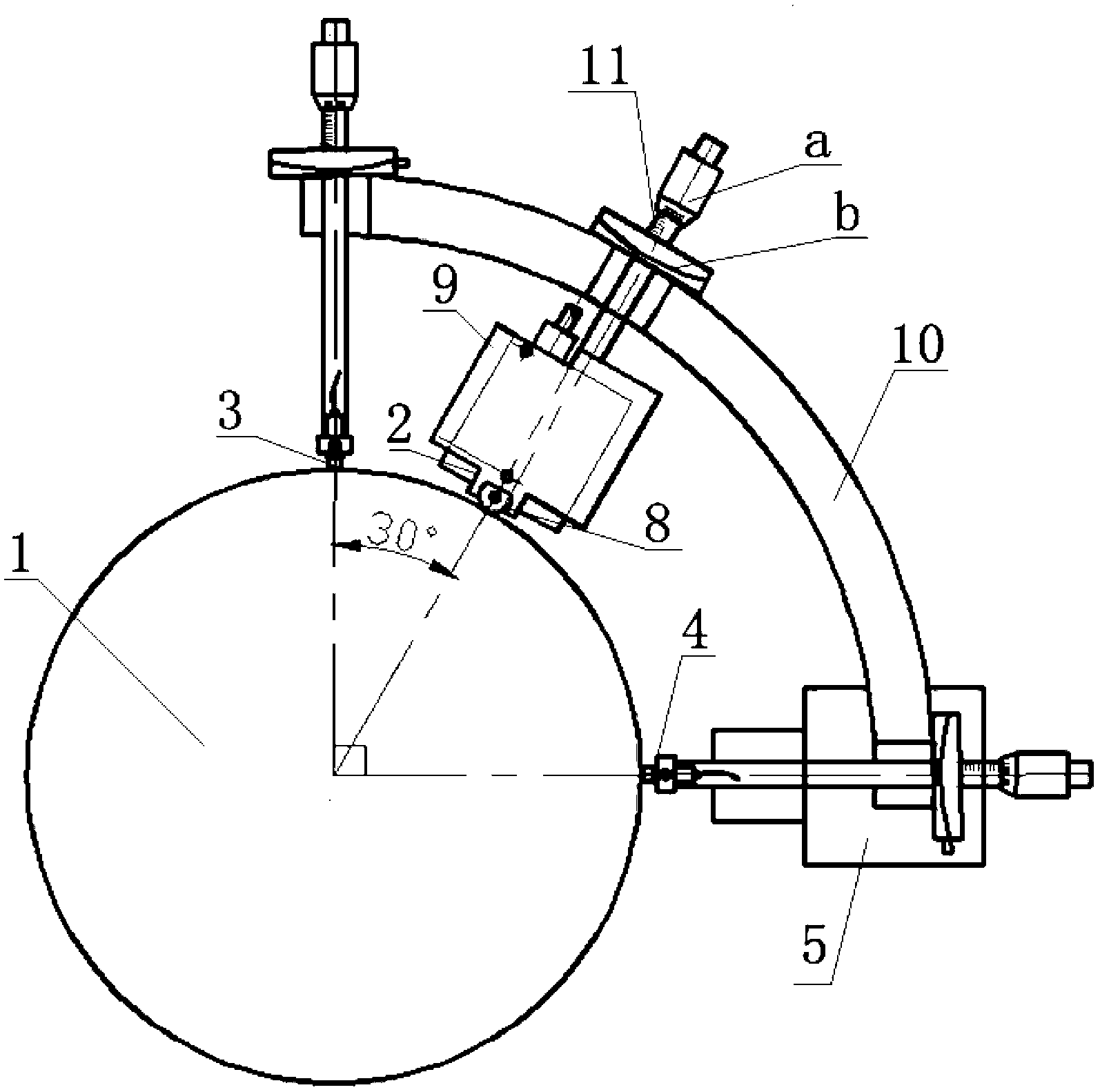

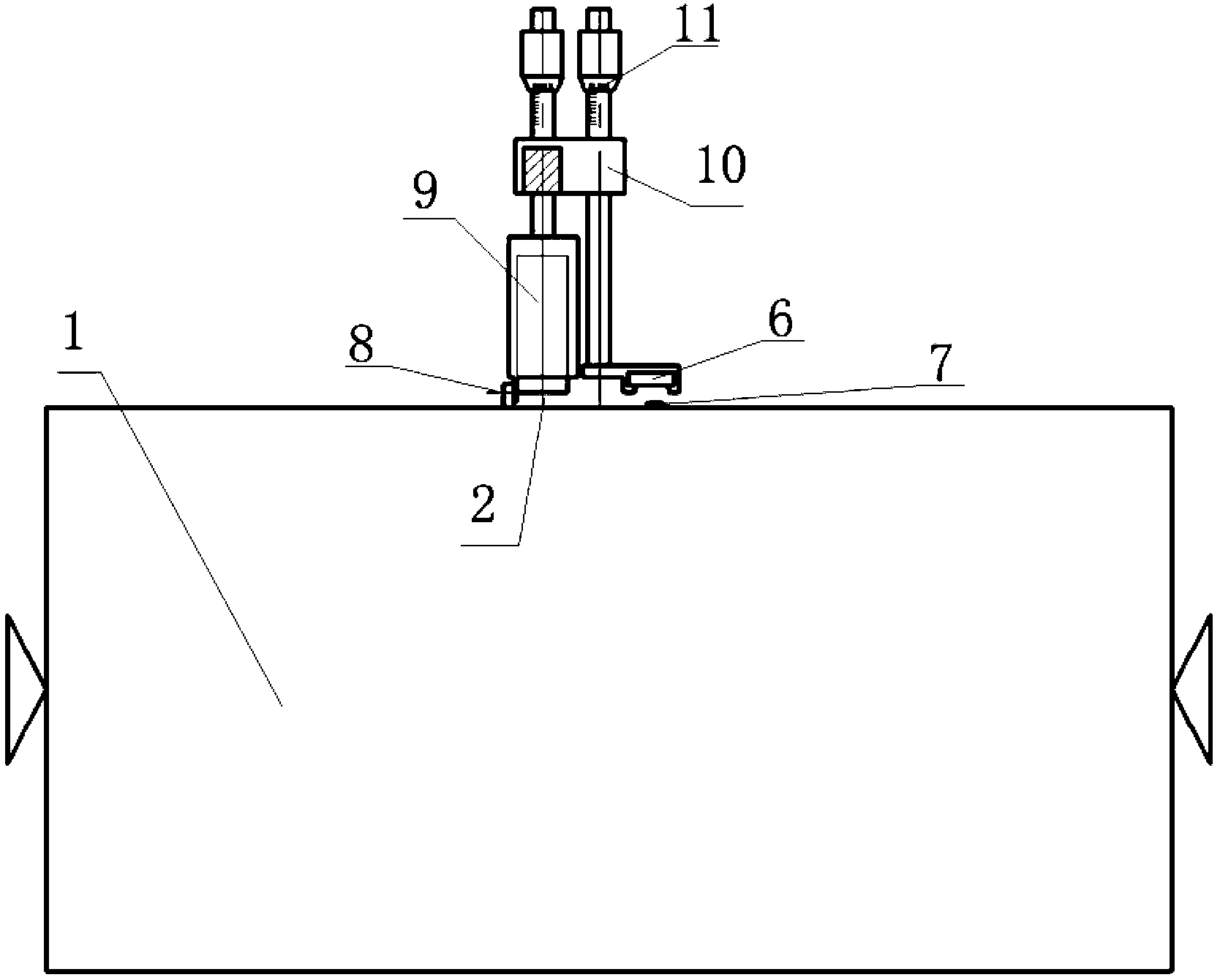

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the electrical runout in-situ measurement device for separating the rotation error of the main shaft described in this embodiment mainly includes a laser displacement sensor 2, a first eddy current sensor 3, a second eddy current sensor 4 and an angle sensor 5. The outer side of the body 1 is provided with a laser displacement sensor 2, a first eddy current sensor 3 and a second eddy current sensor 4, the laser displacement sensor 2 is arranged in the middle position of the first eddy current sensor 3 and the second eddy current sensor 4, the first eddy current sensor The sensor 3, the second eddy current sensor 4 and the laser displacement sensor 2 are arranged on the same circumference, and the circumference where the first eddy current sensor 3, the second eddy current sensor 4 and the laser displacement sensor 2 are located is coaxial with the measured rotating body 1 , the angle sensor 5 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com