A sharpening fixture for single-edged gun drill

A technology for gun drills and fixtures, which is applied to drilling tool accessories, parts of boring machines/drilling machines, drilling/drilling equipment, etc. It can solve the problems of easy bending and deformation of gun drills, and achieve easy operation, firm clamping, and not easy to bend deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure and specific operation of the present invention will be further described below in conjunction with the drawings and embodiments.

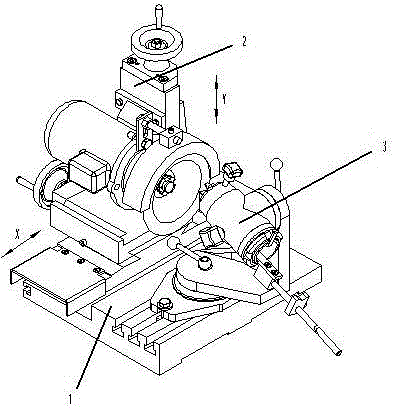

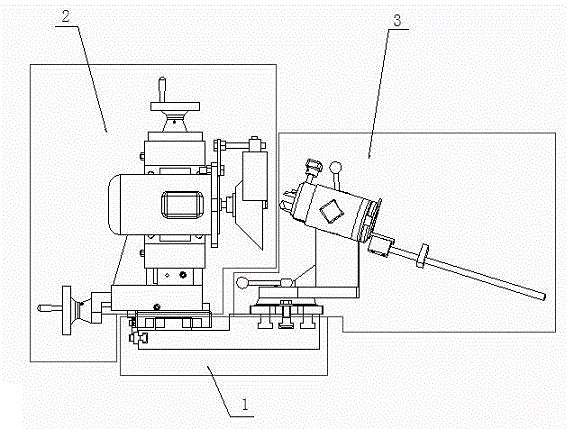

[0020] Such as figure 1 and figure 2 As shown, it shows the overall structure of the gun drill sharpening machine. The gun drill sharpening machine consists of three parts: a base part 1, a slide part 2, and a clamp part 3. The base part 1 is used to support and install the slide part 2 and clamp part 3. The slide table part 2 is equipped with the power devices required for sharpening such as motors and emery wheels. figure 1 The ability to move forward and backward in the X direction and move up and down in the Y direction is shown. The effect of fixture part 3 is to install and fix gun drill, and it has along Figure 4 The A-direction rotation and B-direction rotation capabilities are shown.

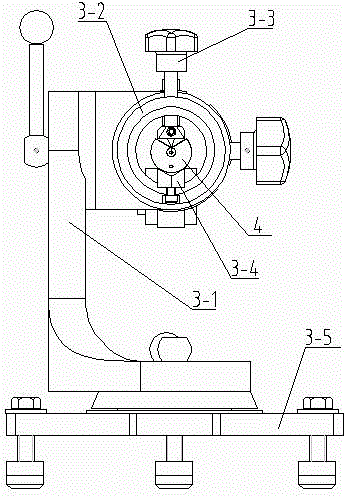

[0021] Such as image 3 As shown, it shows the structure of the clamp part 3, as can be seen from the figure, the clamp part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com