A control device for shifting gears of a driving gearbox

A technology of control device and gear box, which is applied in the direction of transmission device control, belt/chain/gear, components with teeth, etc. Increase the contingency of shifting gears and other issues to achieve the effect of solving the difficulty of shifting gears, solving gear damage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

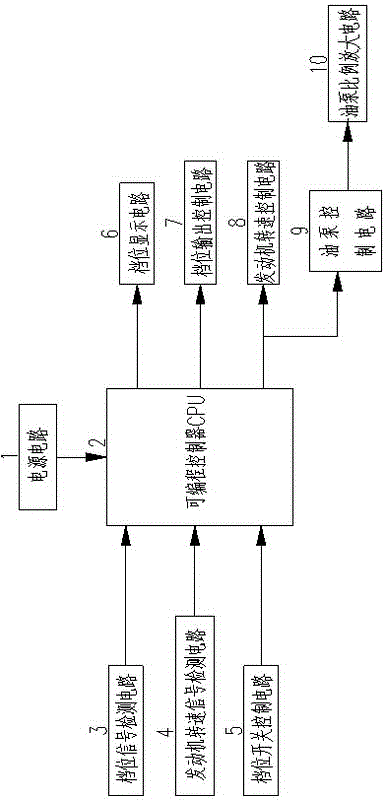

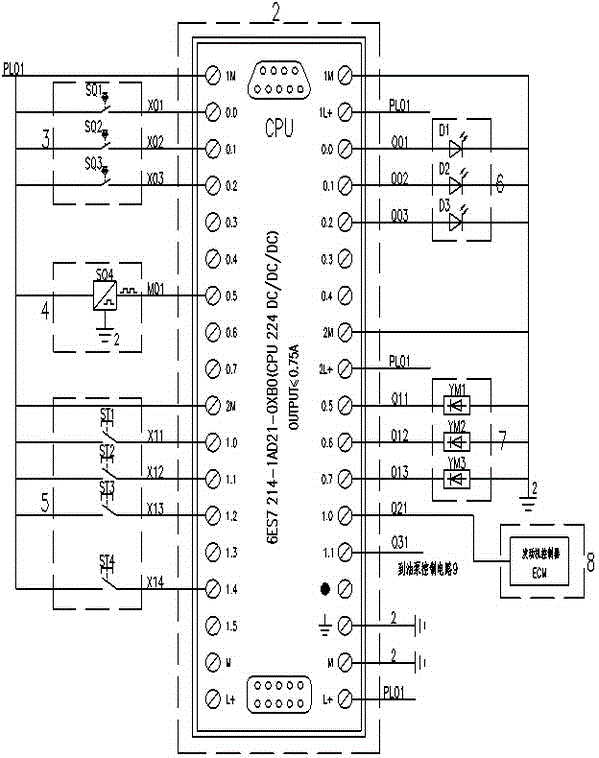

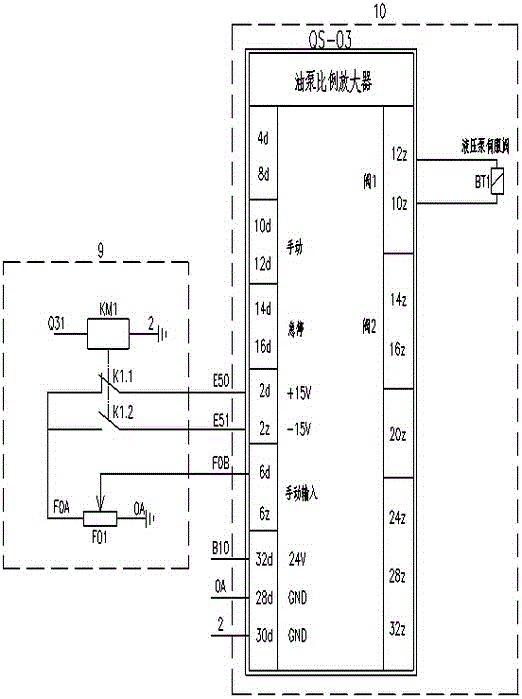

[0034] figure 1 Among them, the power supply circuit 1 is used for the programmable controller 2 and each control circuit to provide 24V DC working power. The input terminals of the programmable controller 2 are respectively connected with the output terminals of the gear position signal detection circuit 3, the engine speed signal detection circuit 4 and the gear position control signal circuit 5, and the output terminals are respectively connected with the gear position control output circuit 7 and the oil pump proportional amplifier circuit 10 And the input end of the gear display circuit 6 is connected.

[0035] The output end of the gear position signal detection circuit 3 is connected to the input end of the programmable controller 2. After the programmable controller 2 detects the gear position signal of the gear box, it is displayed by the gear position display circuit 6 connected thereto.

[0036] The programmable controller 2 samples and calculates the engine speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com