Regenerative cycle and utilization method for papermaking deep-treatment wastewater

A technology for advanced treatment and wastewater, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. The effect of cleaning and regeneration cost, reducing waste water discharge and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

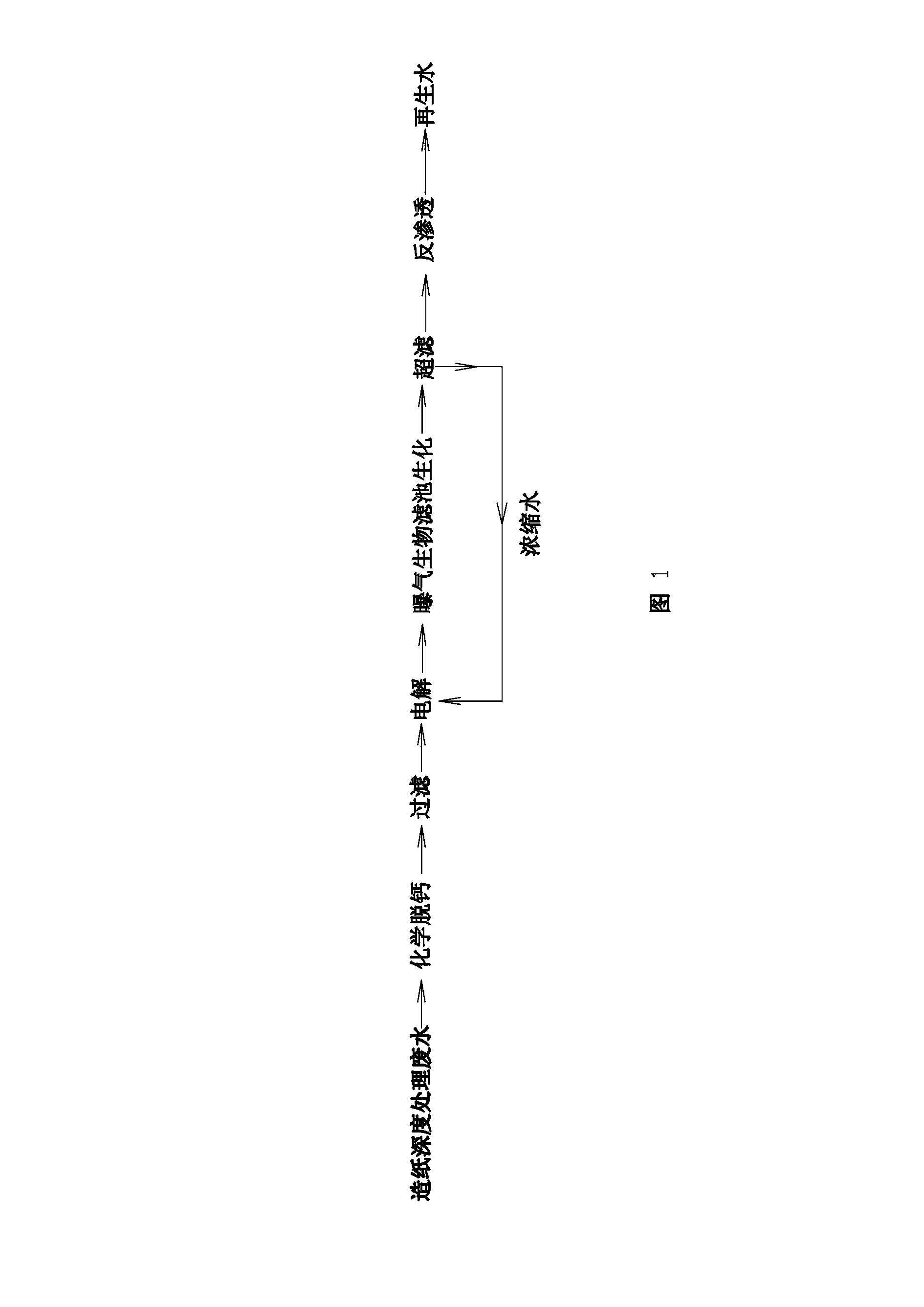

Image

Examples

Embodiment 1

[0043] 500 tons / day papermaking advanced treatment wastewater recycling method.

[0044] The water quality index of the papermaking advanced treatment wastewater was determined as shown in Table 1.

[0045] Table 1 Water quality index of advanced papermaking treatment wastewater

[0046] serial number project unit measured value serial number project unit measured value 1 COD Cr mg / L 150 4 Chroma 60 2 SS mg / L 140 5 Ca mg / L 200 3 Conductivity μS / cm 1800 6 hardness mmol / L 4

[0047] (1) Chemical decalcification

[0048] The papermaking advanced treatment wastewater flows into the coagulation tank through the pipeline. In the coagulation tank, an appropriate amount of saturated lime solution is added under stirring to adjust the pH value to 8.5, and then 600mg / L of Na is added. 2 CO 3 , and then add 10 mg / L FeSO 4 , then add Na 2 CO 3 Inversely adjust the pH value to 8, and finally add 2mg / L polyphen...

Embodiment 2

[0065] Recycling and recycling method of 6000 tons / day advanced papermaking wastewater treatment.

[0066] The water quality index of the described papermaking advanced treatment wastewater was determined as shown in Table 3.

[0067] Table 3 Water quality indicators of advanced papermaking wastewater treatment

[0068] serial number project unit measured value serial number project unit measured value 1 COD Cr mg / L 90 4 Chroma 150 2 SS mg / L 60 5 Ca mg / L 160 3 Conductivity μS / cm 1200 6 hardness mmol / L 2

[0069] (1) Chemical decalcification

[0070] The papermaking advanced treatment wastewater flows into the coagulation tank through the pipeline. In the coagulation tank, an appropriate amount of saturated lime solution is added under stirring to adjust the pH value to 9.5, and then 300mg / L of Na is added. 2 CO 3 , then add 5mg / L FeSO 4 , then add Na 2 CO 3 Inversely adjust the pH value to 9, and ...

Embodiment 3

[0087] 20,000 tons / day papermaking advanced treatment wastewater recycling method.

[0088] The water quality index of the described papermaking advanced treatment wastewater was determined as shown in Table 5.

[0089] Table 5 Water quality indicators of advanced papermaking wastewater treatment

[0090] serial number project unit measured value serial number project unit measured value 1 COD Cr mg / L 120 4 Chroma 80 2 SS mg / L 120 5 Ca mg / L 200 3 Conductivity μS / cm 1500 6 hardness mmol / L 1.2

[0091] (1) Chemical decalcification

[0092]The papermaking advanced treatment wastewater flows into the coagulation tank through the pipeline. In the coagulation tank, an appropriate amount of saturated lime solution is first added to adjust the pH to 9 through the dosing device under stirring, and then 500 mg / L of Na is added. 2 CO 3 , then add 8 mg / L FeSO 4 , then add Na 2 CO 3 Inversely adjust the pH val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Chroma | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap