Assembling method of plastic-wood house easy to assemble and disassemble

An assembly method and plastic-wood technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of labor-intensive, non-professionals, inconvenient transportation, etc., to achieve tight house structure and solve connection difficulties. , the effect of easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below by specific examples.

[0021] All parts of the easy-to-assemble and disassemble plastic-wood house are pre-processed, and the assembly and disassembly are completed by screws or connectors. The installation steps of the embodiment are as follows:

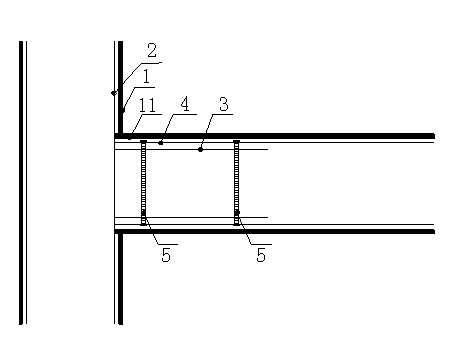

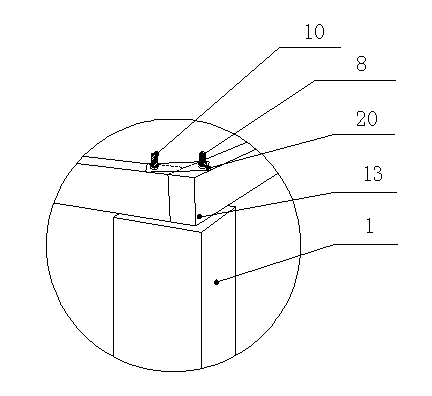

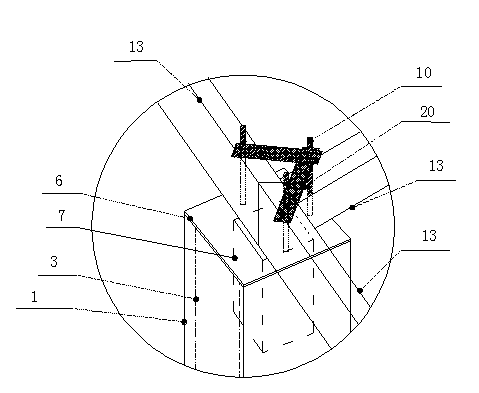

[0022] 1. Column 1 is connected with foundation beam 11 and waist frame 12, as attached figure 1 Shown:

[0023] ①In the column 1, the corresponding parts of the foundation beam 11 and the waist frame 12 are to be milled. Then weld the steel pipe on the orifice column lined steel pipe 2 as the implant pipe 3, and the size of the implant pipe 3 is to be able to be inserted into the foundation beam lined steel pipe 4 or the waist frame lined steel pipe; The inlet pipe 3 is inserted into the base beam lined steel pipe 4 or the waist frame lined steel pipe; ③ the foundation beam 11, the waist frame 12, and the implant pipe 3 are respectively drilled, and the foundation bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com