Omnibearing multi-angle rotating-type anchor rod drill wagon

A bolter, multi-angle technology, applied in earthwork drilling, bolt installation, drilling equipment, etc., can solve the problems of reducing construction efficiency, and achieve the goal of improving construction efficiency, providing drilling accuracy and efficiency, and precise positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

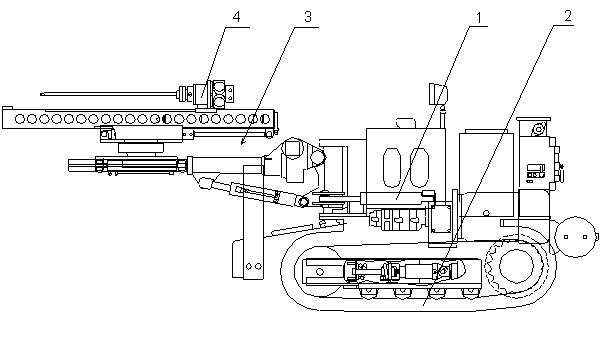

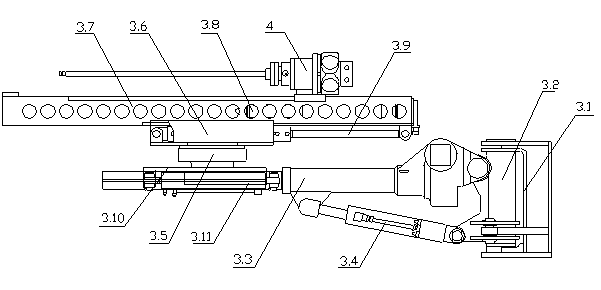

[0020] see figure 1 with figure 2 , the present invention relates to an all-round multi-angle rotary rock bolter, the drill car includes a body 1 arranged on a crawler mechanism 2, and a power head 4 is connected to the body 1 through a rotating support mechanism 3 , the power head 4 is used to provide driving power for the drill rod or anchor rod, the rotating support mechanism 3 includes a connecting frame 3.1 connected to the body 1, a rotary shaft 3.2 is vertically installed on the connecting frame 3.1, and a drill The right end of the arm 3.3 is hinged on the rotary shaft 3.2, one end of a pitch cylinder 3.4 is hinged on the middle part of the drilling arm 3.3, and the other end is hinged on the rotary shaft 3.2, and a rotary reducer is installed on the left half of the drilling arm 3.3 3.5 (specifically, the drill arm 3.3 is a hollow structure, and a worm driven by a motor is installed in the middle cavity, and the worm is matched with the worm gear of the rotary reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com