Top packer for sand control

A packer and sand control technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of casing inner wall bite damage, setting, small hanging load, etc., and achieve simple assembly procedures , On-site operation is simple, the effect of strong suspension ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

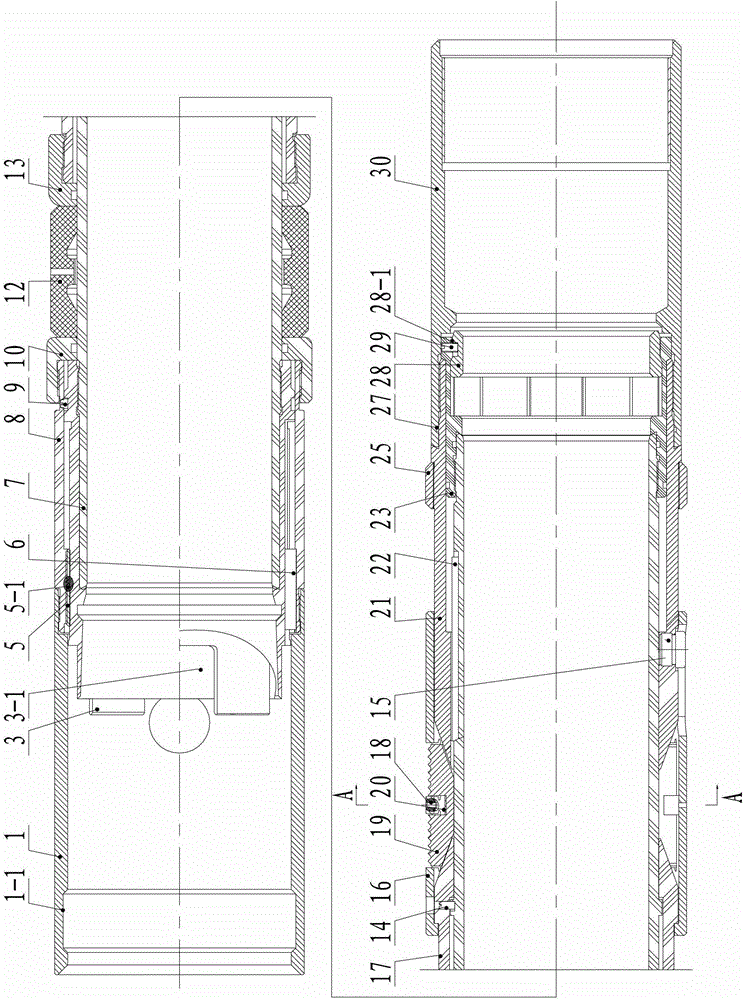

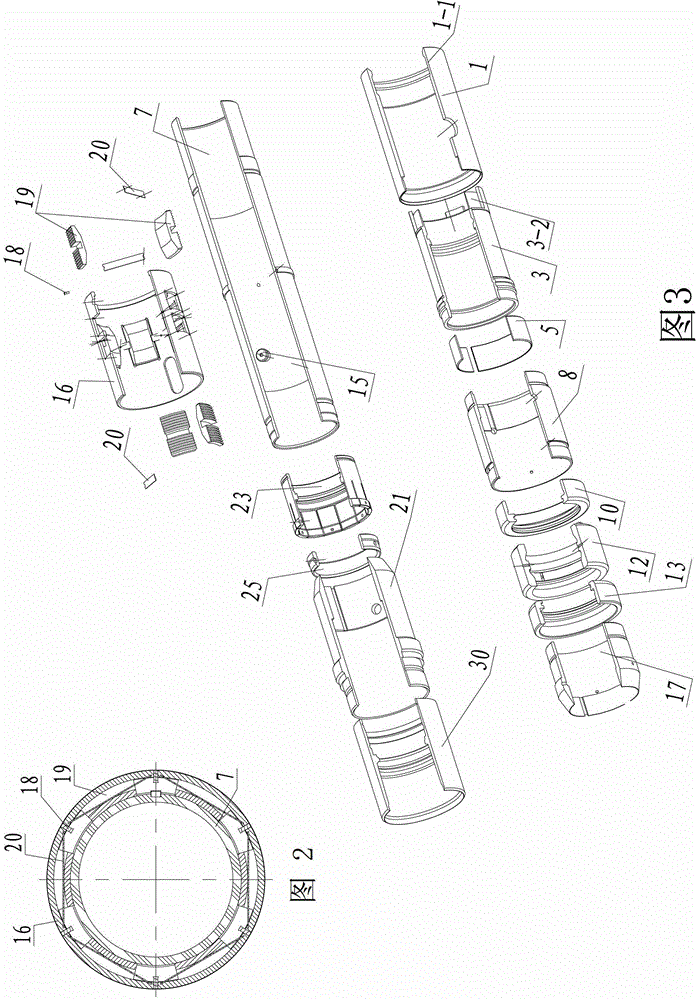

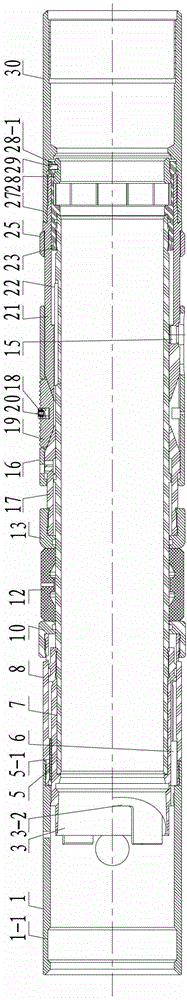

[0034] see Figure 1 to Figure 3 , a top packer for sand control, including an upper joint 3 and a lower joint 30, a central pipe 7 is arranged below the slit through the slit in the middle of the upper joint in the upper joint, and also includes a setting mechanism, a locking mechanism, an anchor Fixing mechanism, sealing mechanism and unsealing mechanism.

[0035] The setting mechanism includes a pressure sleeve 1 sleeved on the outside of the upper joint and a first shear pin 9 radially provided on the outside of the bottom of the upper joint for blocking the downward movement of the connecting sleeve.

[0036] The locking mechanism includes a connecting sleeve 8 which is threadedly connected with the pressure sleeve below the pressure sleeve, and a lock ring 5 connected with the upper joint with a sawtooth thread 5-1 is arranged in the space between the outer side of the upper joint and the inner side of the pressure sleeve.

[0037] The sealing mechanism is located under...

Embodiment 2

[0046] see Figures 6 to 8 , this embodiment is mostly the same as Embodiment 1, the only difference is that each slip 19 includes two outward protrusions, the protrusions are provided with slip teeth, and the slip sleeve is provided with a number of accommodating clips at intervals. A hole through which the protruding part of the shoe passes outwards and whose shape and size match the tangential section of the protruding part of the slip. The two protruding parts of each slip protrude or retract from the adjacent hole. The middle of the two protruding parts It is a groove extending in the axial direction. There is a spring piece inside the groove. The spring piece is bow-shaped. in the slot. On the top of the slips in the slip sleeve, an open ring 31 is also fixed by rivets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com