Control method for emptying air in underground filling riser by using cut-off valve

A control method and shut-off valve technology, which is applied to the control of emptying the air in the underground filling standpipe. The shut-off valve is used to empty the control field of the air in the underground filling standpipe, which can solve the problems of impact, gas blockage at the pipeline standpipe, etc. , to achieve the effect of accurate control and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

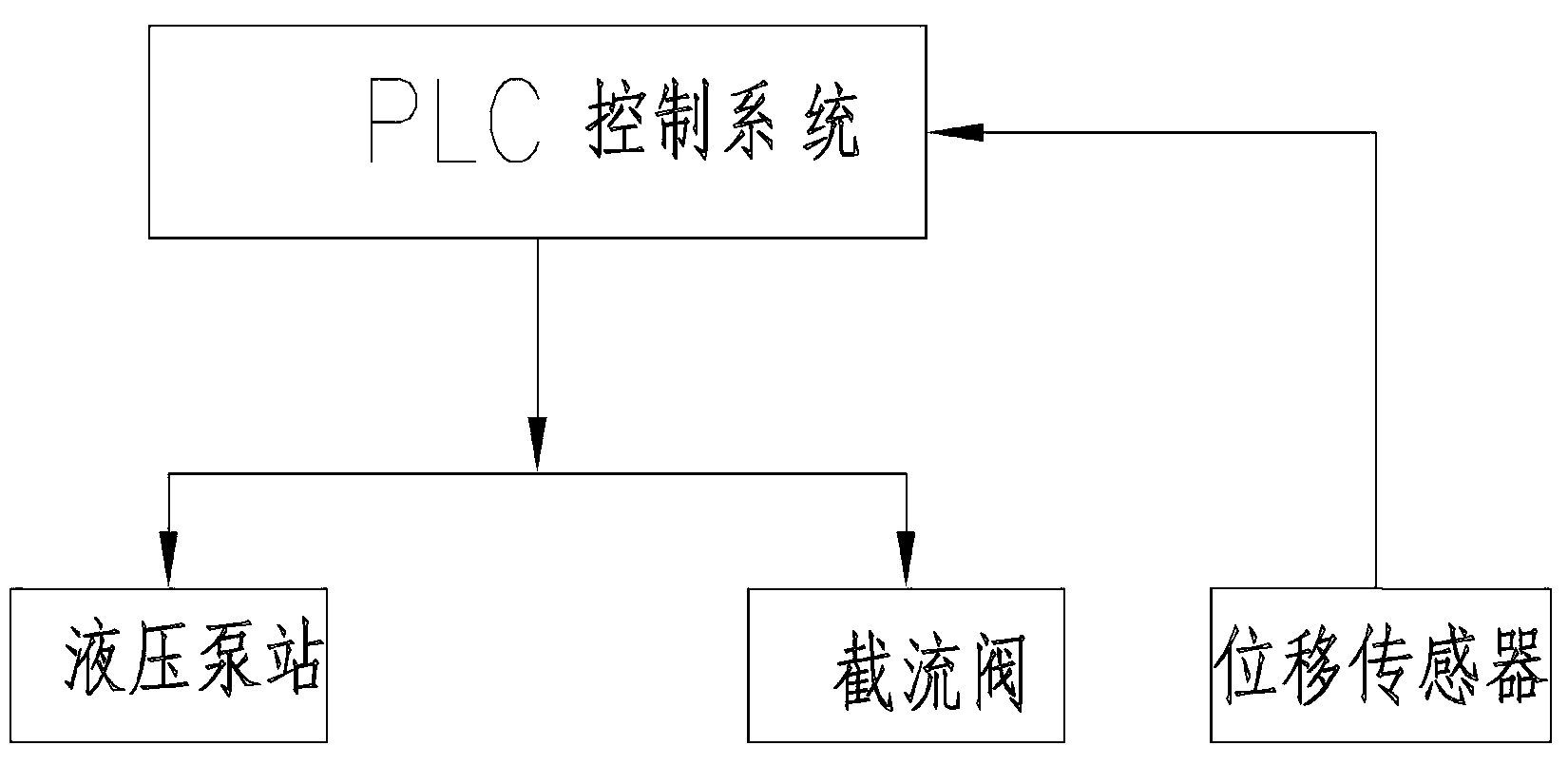

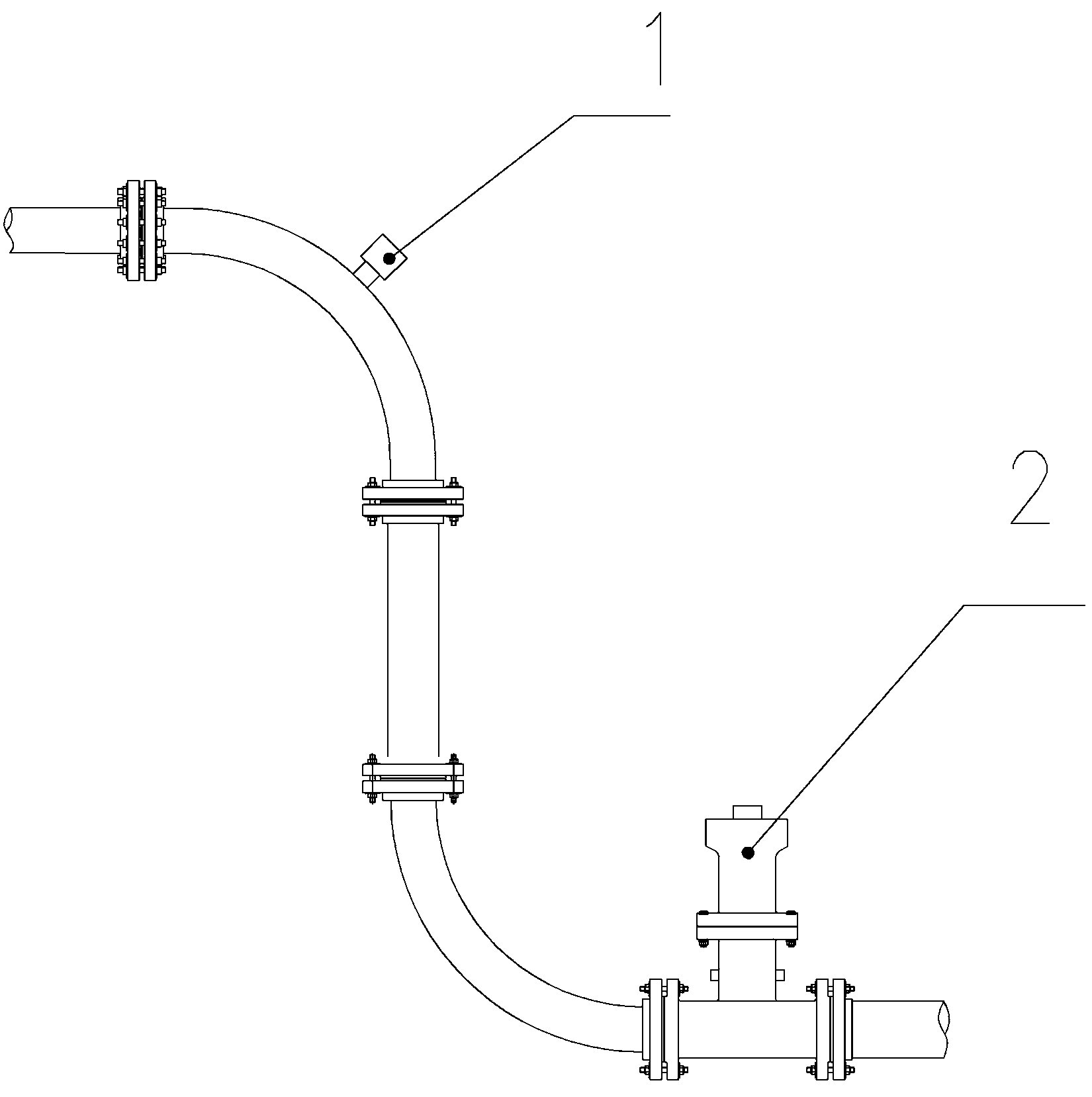

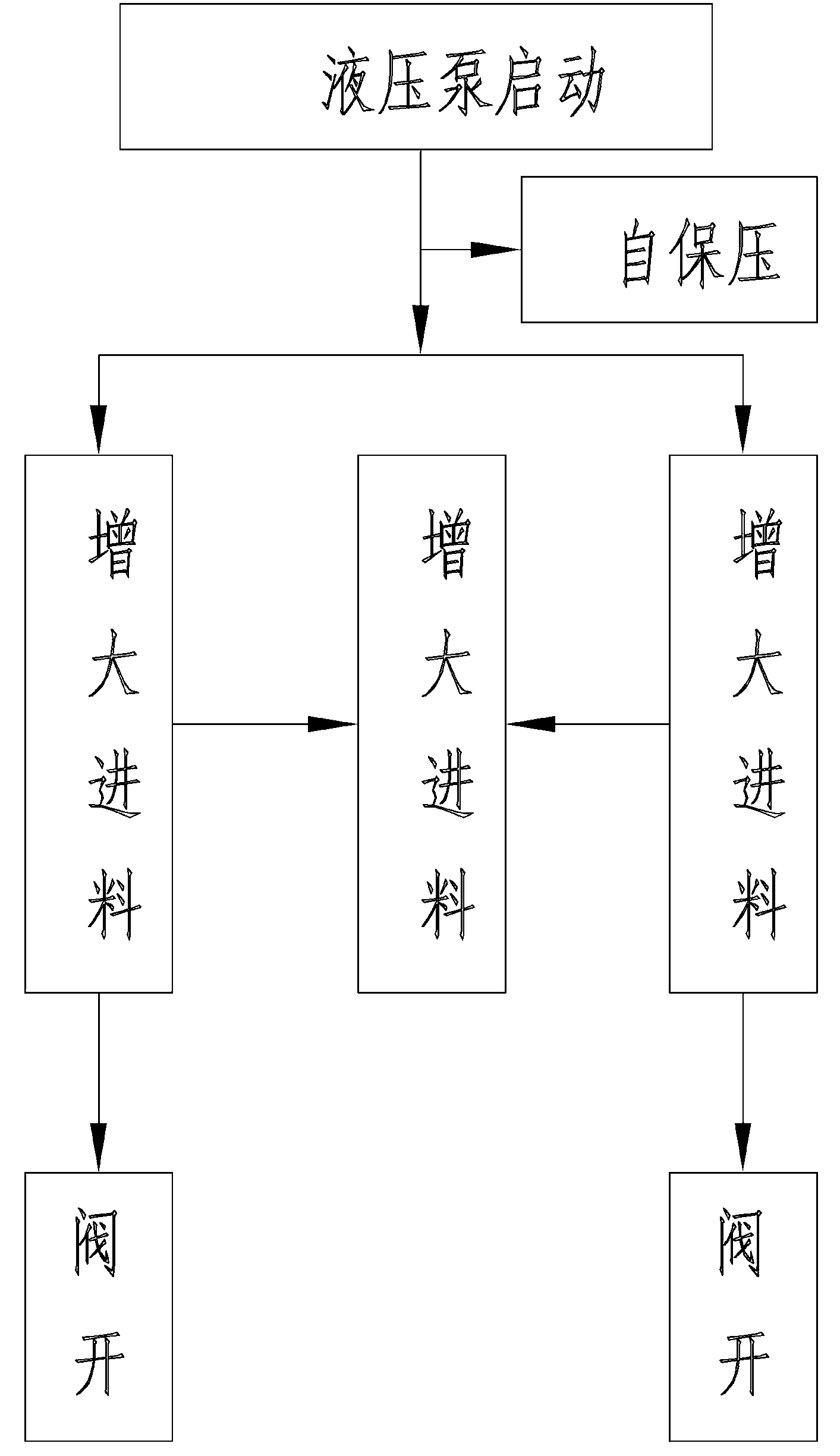

[0013] Such as Figure 1 ~ Figure 3 As shown, the control method of using the shut-off valve to empty the air in the underground filling standpipe includes a hydraulic pump station, a shut-off valve, a displacement sensor, and a PLC control system, wherein the PLC control system is connected to the hydraulic pump station and the shut-off valve through control cables. The hydraulic pump station is connected to the shut-off valve through the oil pipe, and the displacement sensor installed on the shut-off valve transmits the real-time value to the PLC control system through the PLC analog module, and the PLC control system controls the shut-off according to the real-time value transmitted by the displacement sensor The size of the valve opening is used to empty the air in the downhole filling standpipe.

[0014] The implementation steps are as follows.

[0015] Attached figure 1 Set up the control system, according to the attached figure 2 The indicated valve position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com