Reducing two-way throttling short tube

A two-way throttling and short tube technology, which is applied in the direction of fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve the problems of increasing material costs, achieve the effects of reducing welding joints, avoiding vibration and noise, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

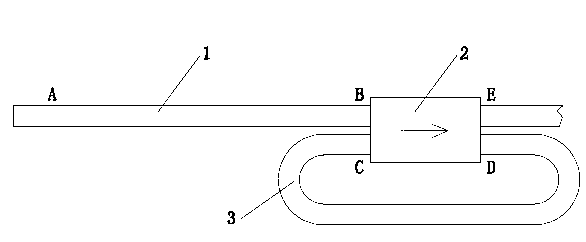

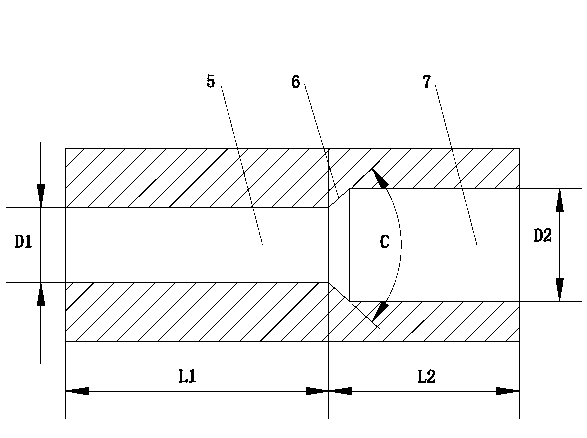

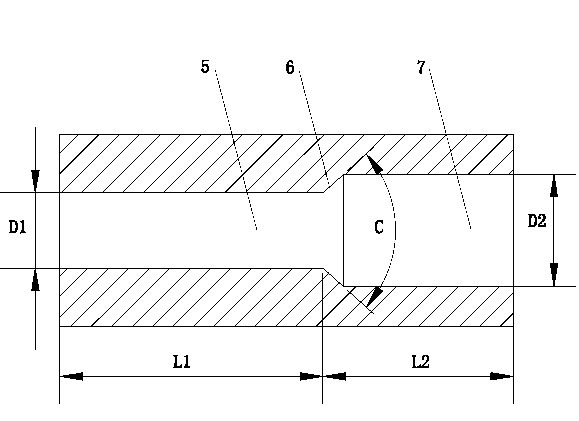

[0015] like figure 1 , 2 As shown, it is a variable-diameter two-way throttling short tube, including two or more short tubes with different diameters. The short tubes are arranged in sequence according to the inner diameter and connected in series to form a variable-diameter two-way throttle short tube. The adjacent short pipes can be connected by welding; the length of each short pipe is 2mm to 30mm, the inner pipe diameter D1 of the first section of pipe 5 at the beginning end is the smallest, and D1 is 0.4mm to 1.1mm, and the inner pipe of the adjacent second section of pipe 7 Diameter D2 is 1.1 to 2 times of D1, and the inner diameter D3 of the third section of pipe adjacent to the second section of pipe 7 is 1.1 to 2 times of D2, and so on. The inner diameter of the nth section of pipe is the nth - 1.1 to 2 times the inner diameter of the first section of pipe, the inner diameter of the nth section of pipe at the end is the largest, and n is a natural number. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com