A kind of manufacturing method of palladium-plated silver-plated double-coated bonding copper wire

A technology for bonding copper wire and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] (2) After the copper core is roughly drawn to obtain a copper wire with a diameter of about 3-4 mm, the copper wire is annealed at about 450-500 degrees Celsius, and the annealing time is about 20-60 minutes , water cooling after annealing;

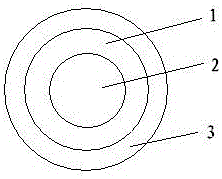

[0016] (3) electroplating pure palladium conductive layer: electroplating 3.3~4.2wt% pure palladium on the surface of the copper core after annealing to form a pure palladium conductive layer, the purity of the pure palladium is greater than 99.99%;

[0017] (4) The first fine drawing: the copper wire plated with pure palladium conductive layer after step (3) is finely drawn into a palladium-coated copper wire with a diameter of about 1-2mm;

[0018] (5) The first thermal annealing: perform thermal annealing on the palladium-coated copper wire that has completed step (4), wherein the thermal annealing temperature is about 450-500 degrees Celsius, and the time is about 20-60 minutes;

[0019] (6) electroplating pure silver conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com