Testing site for whole scene parking calibration and constructing method thereof

An on-site, panoramic technology, applied in the direction of TV, electrical components, image communication, etc., can solve the problems of difficult layout and construction of the test site, difficult to relocate, etc., and achieve the effect of simplifying the layout and simplifying the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

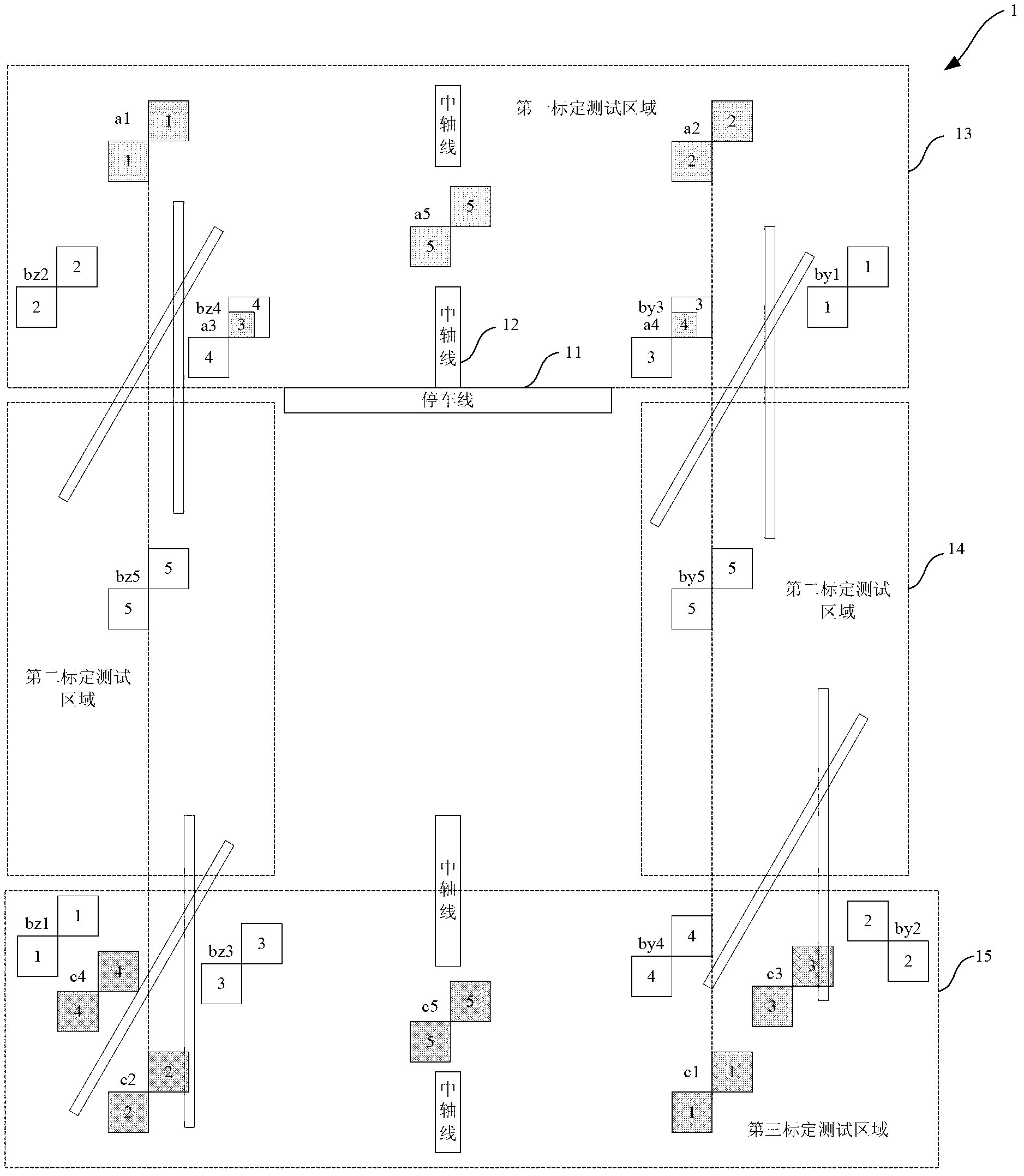

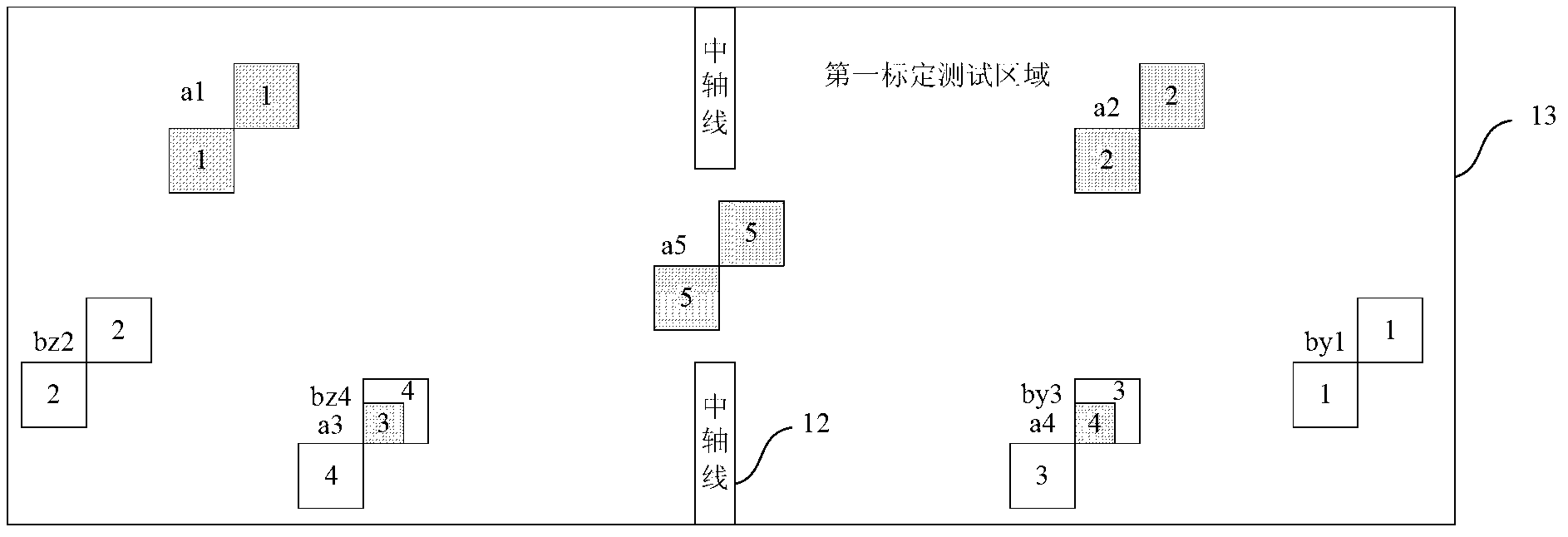

[0040] like figure 1 As shown, the present invention provides a test site for panoramic parking calibration. The test site 1 is used to provide a site for panorama correction for vehicles equipped with a panorama parking system. The test site 1 includes: a parking line 11 , a central axis 12 , a first calibration test area 13 , a second calibration test area 14 , and a third calibration test area 15 .

[0041] The parking line 11 is used to indicate the parking position of the front end of the vehicle. In this embodiment, the stop line 11 is located at the middle front of the test site 1 to remind the driver of the vehicle to stop the front of the vehicle above the line.

[0042] The central axis 12 is perpendicular to the parking line 11 and is used to demarcate the central axis of the vehicle. In this embodiment, the central axis 12 bisects the parking line 11 , which is used to prompt the driver of the vehicle to park the vehicle in the middle on the central axis 12 .

...

Embodiment 2

[0072] The present invention also provides a method for building a test site 1 for panoramic parking calibration.

[0073] The method of constructing the test site 1 is as follows:

[0074] Mark the parking line 11 used to indicate the parking position of the front end of the vehicle at the test site 1, and the central axis 12 perpendicular to the parking line 11 and used to mark the central axis of the vehicle;

[0075] In the first calibration test area 13 in front of the vehicle, the first calibration point a5 is arranged on the central axis 12 according to a preset value away from the parking line 11;

[0076] In the first calibration test area 13 in front of the vehicle, the first calibration points a1 and a2 symmetrical along the central axis 12 are arranged obliquely in front of the vehicle according to the preset distance from the parking line 11 and the central axis 12, wherein The preset distance d1 of the central axis 12 is greater than half of the stop line 11;

...

Embodiment 3

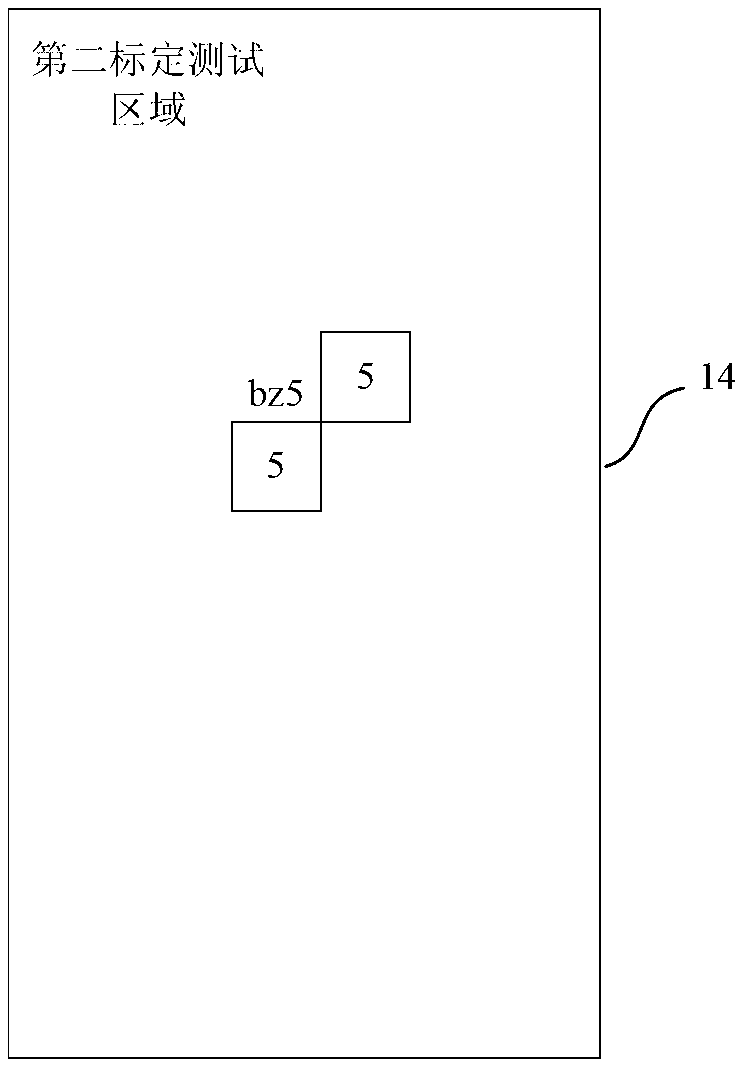

[0086] As a preferred option, such as Figure 2a , 2b , 2c, according to the above-mentioned respective first calibration points, second calibration points and third calibration points and the corresponding positional relationship between the parking line 11 and the central axis 12, the above-mentioned first calibration test area is made in advance 13. The patch of the second calibration test area 14 and the third calibration test area 15 . The first calibration test area 13 , the second calibration test area 14 , and the third calibration test area 15 can be made of polyvinyl chloride, polypropylene and other non-deformable plastic cloth or advertising cloth.

[0087] The method of constructing the test site 1 is as follows:

[0088] Mark the parking line 11 used to indicate the parking position of the front end of the vehicle at the test site 1, and the central axis 12 perpendicular to the parking line 11 and used to mark the central axis of the vehicle;

[0089] Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com