Multi-die MEMS package

A controller and device layer technology, applied in the direction of measuring devices, decorative arts, microstructure devices, etc., can solve the problems of expensive, cost-increased, not completely standardized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 12

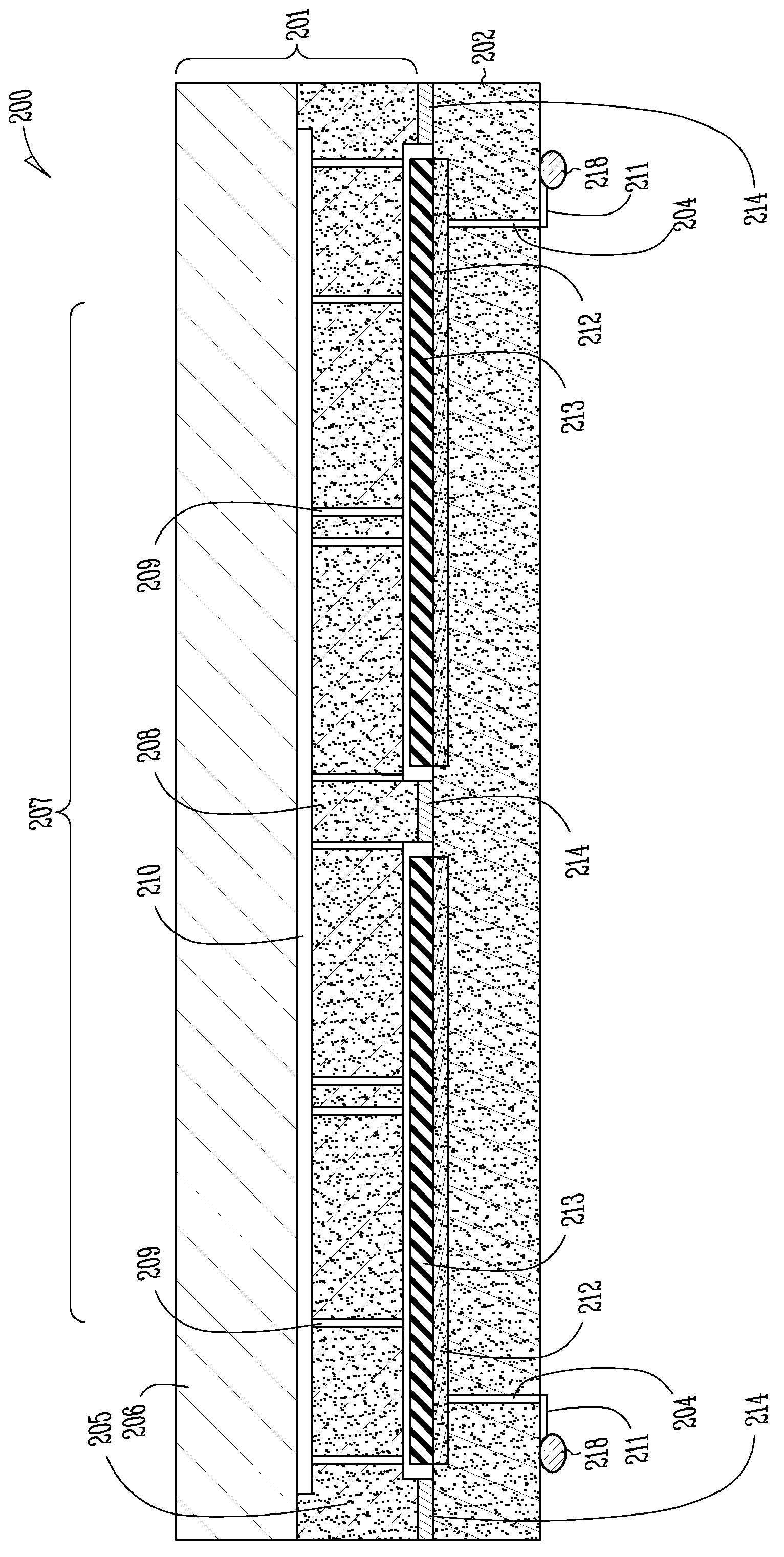

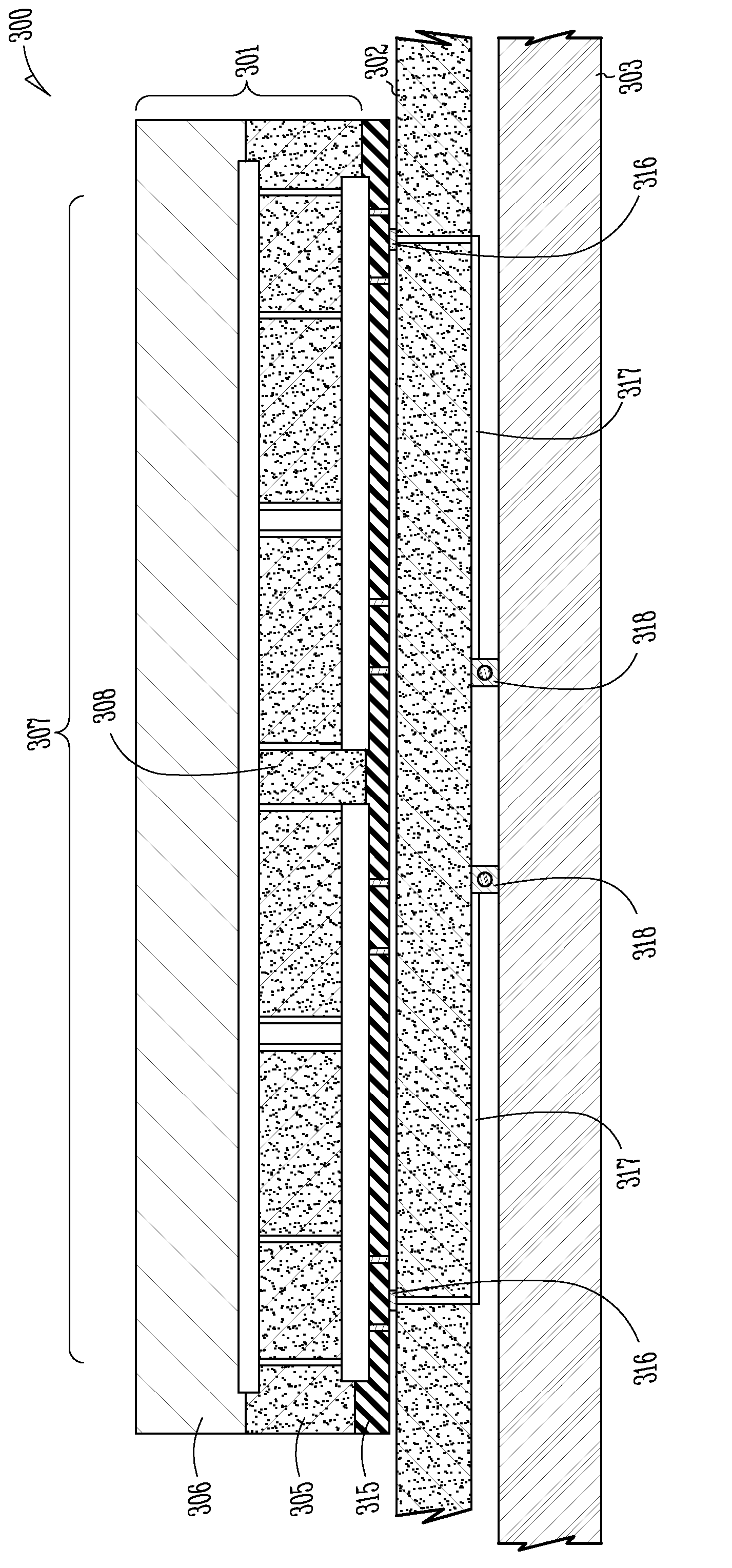

[0029] In Example 12, an apparatus can include a microelectromechanical system (MEMS) integrated circuit (IC) and a controller IC. The MEMS IC may include: a device layer having a plurality of gaps forming a plurality of movable portions and a single anchor configured to support the plurality of movable portions; and A protective layer coupled to the device layer and configured to maintain a vacuum around the plurality of movable portions and restrict out-of-plane movement of the plurality of movable portions. The controller IC has a first side coupled to the MEMS IC, and the controller IC may include a through silicon via extending through the controller IC from the first side to the the second side of the controller IC. The through-silicon vias may be configured to electrically couple contacts on the first side of the controller IC with contacts on the second side of the controller IC.

[0030] In Example 13, the MEMS IC of any one or more of Examples 1-12 optionally inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com