Enamel powder removing device

An enamel powder, together technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of porcelain powder falling to the ground, affecting environmental cleaning, affecting the next process, etc., saving enamel powder and knocking powder cleanly , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

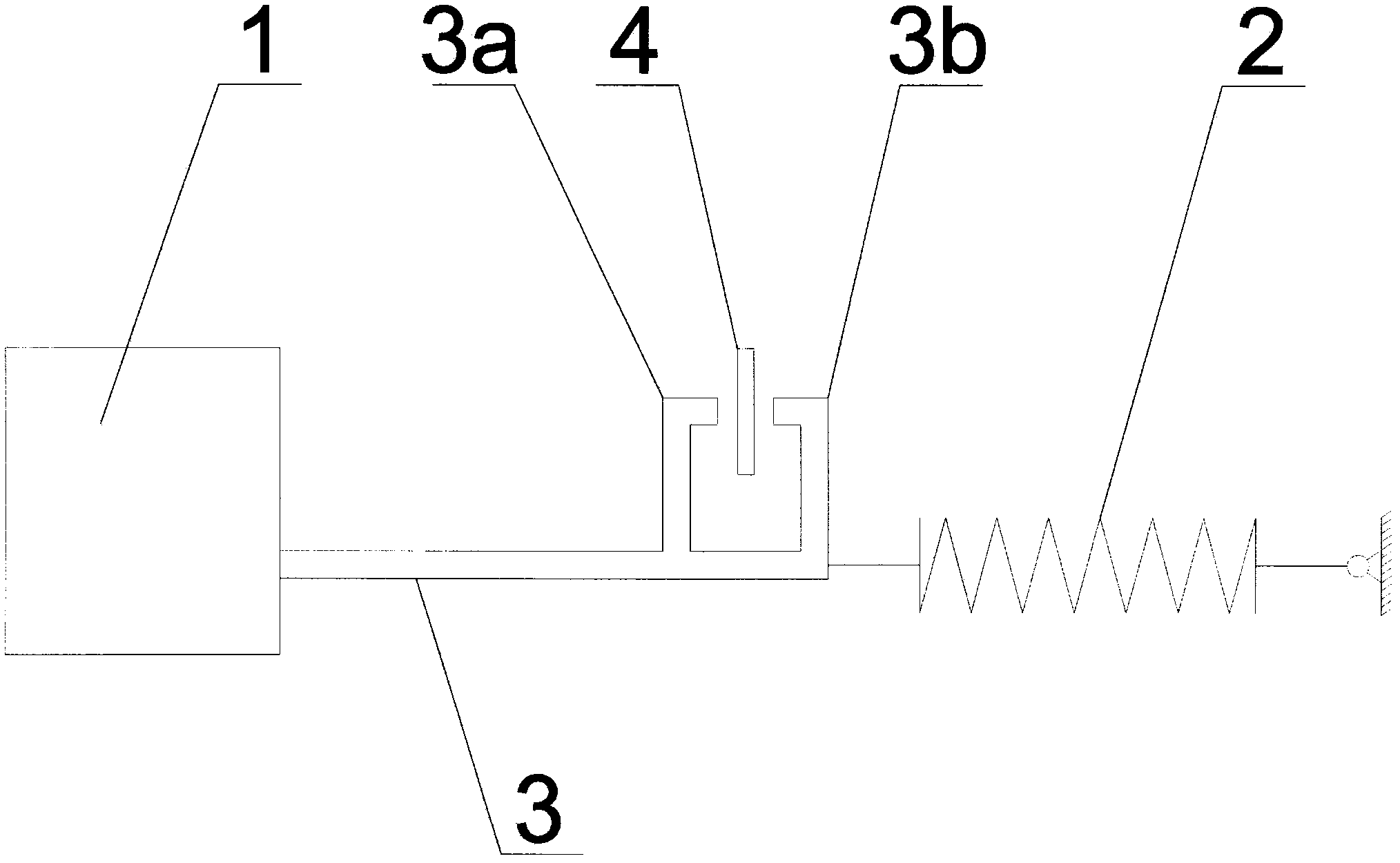

[0009] Such as figure 1 As shown, a kind of enamel powder removal device of the present invention is made up of electromagnet 1, return spring 2, knock bar 3, and one end of described knock bar 3 is fixedly connected with electromagnet 1, and the end of described knock bar 3 The other end is processed with facing knocking protrusions 3 a and 3 b at a certain distance, one end of the return spring 2 is fixed, and the other end is connected to one end of the knocking rod 3 .

[0010] When the electromagnet 1 is energized, the knock rod 3 is pulled, and the opposite knock protrusions 3a and 3b hit the workpiece support 4. When the electromagnet 1 is powered off, the knock rod 3 is pulled back by the return spring 2. When the electromagnet 1 is energized repeatedly , When the power is cut off, the knocking protrusions 3a and 3b will hit the workpiece support 4 continuously, and the enamel powder on the support 4 will be removed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap