An electronic synchronization device for an automatic bar feeding machine

A technology of automatic feeding and synchronizing device, applied in metal processing equipment and other directions, can solve the problems of fracture, small clip and material, clip detachment from material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

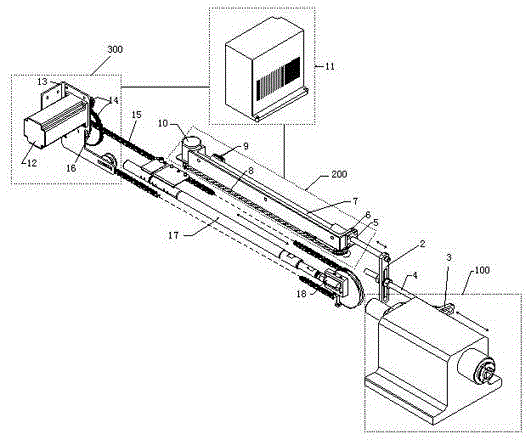

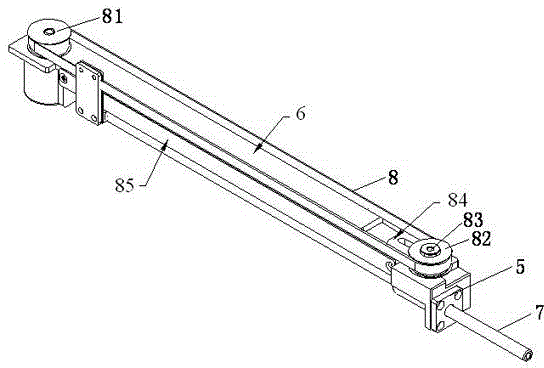

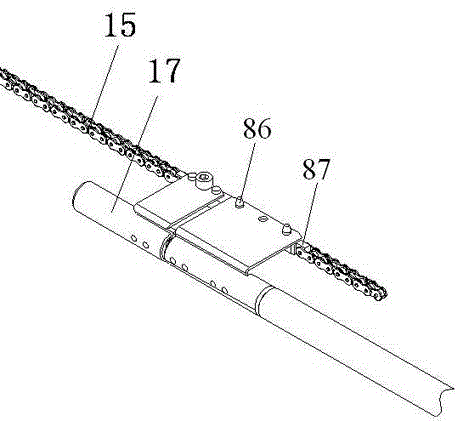

[0008] Such as figure 1 , figure 2 and image 3 As shown, an electronic synchronization device for an automatic bar feeder includes a lathe spindle body, a first synchronization device, and a second synchronization device. The lathe spindle body is connected to the first synchronization device, and the first synchronization device Servo connection with the second synchronous device through a servo amplifier; the first synchronous device includes a base, a linear bearing, a transmission shaft, a first pulley, a second pulley, and a and the timing belt on the periphery of the second pulley, a rotary encoder and a combination seat, the first pulley and the second pulley are installed on the base through the pulley mandrel respectively, and the linear bearing is installed on the end of the base, The transmission shaft is installed in the linear bearing, and also includes a clamping device, the lower part of the clamping device is fixedly connected with one end of the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com