Flexible printed circuit (FPC) steel piece producing machine

A technology for producing machines and steel sheets, which is applied in the field of machinery, can solve problems such as lower production efficiency, easy deformation, and long FPC steel sheets, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

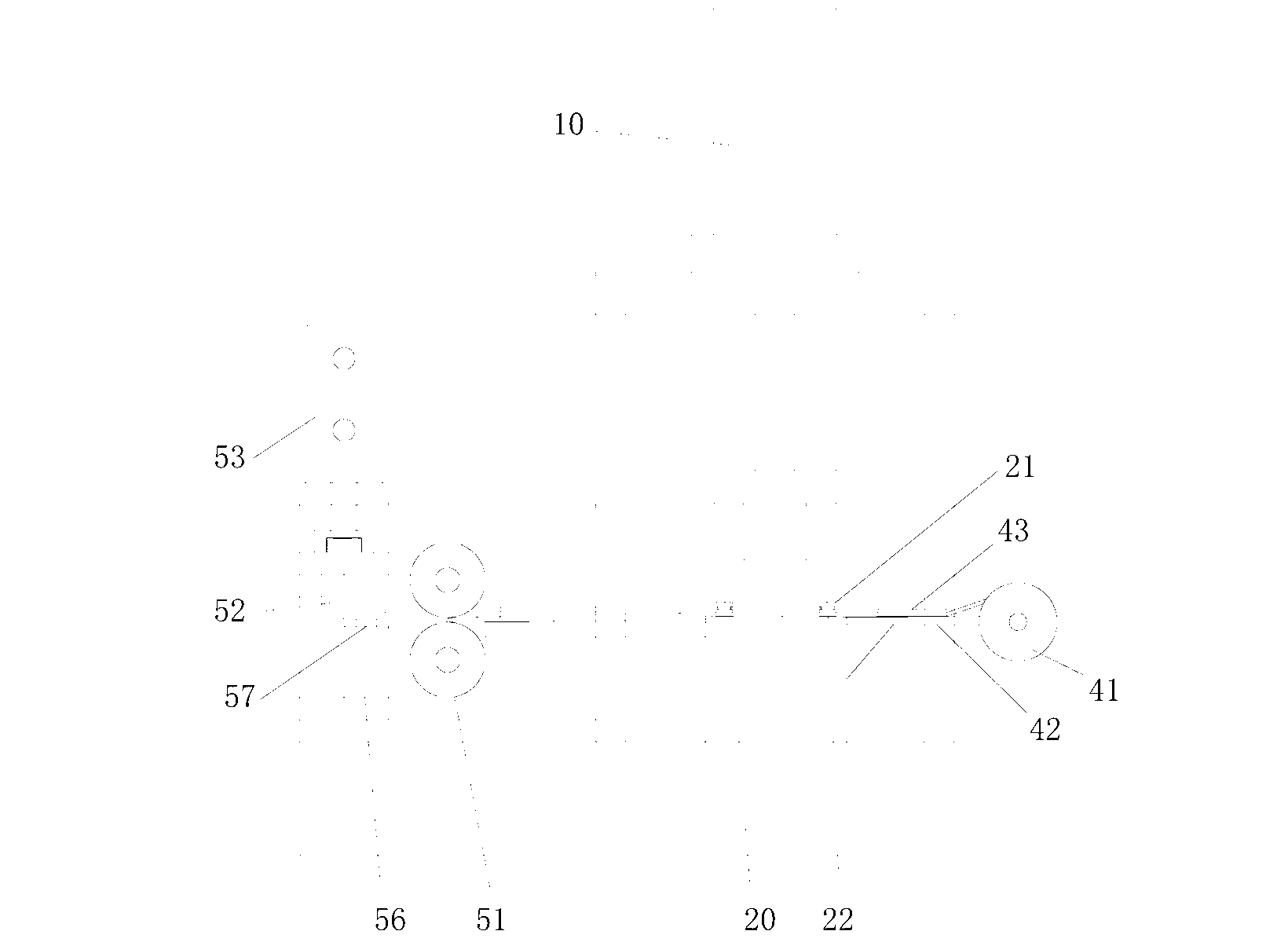

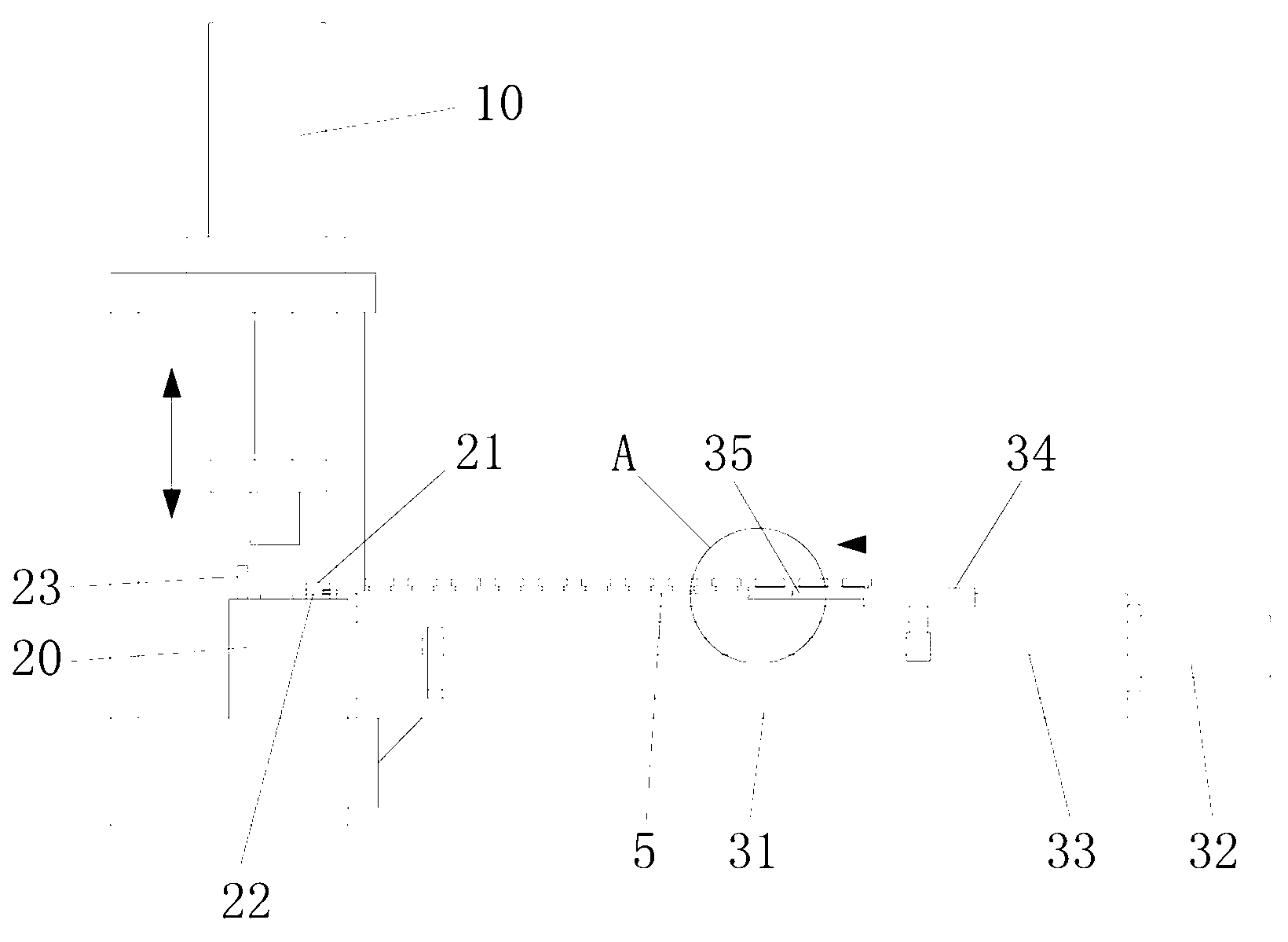

[0016] as attached figure 1 to attach image 3 A kind of FPC steel sheet production machine shown, comprises stamping machine 10 and is installed on the processing platform 20 on the stamping machine 10, one side of described processing platform 20 is provided with sheet material feeding device, and a vertical of described sheet material feeding device A film feeding device is provided on one side, and a film shearing device is provided on the side opposite to the film feeding device.

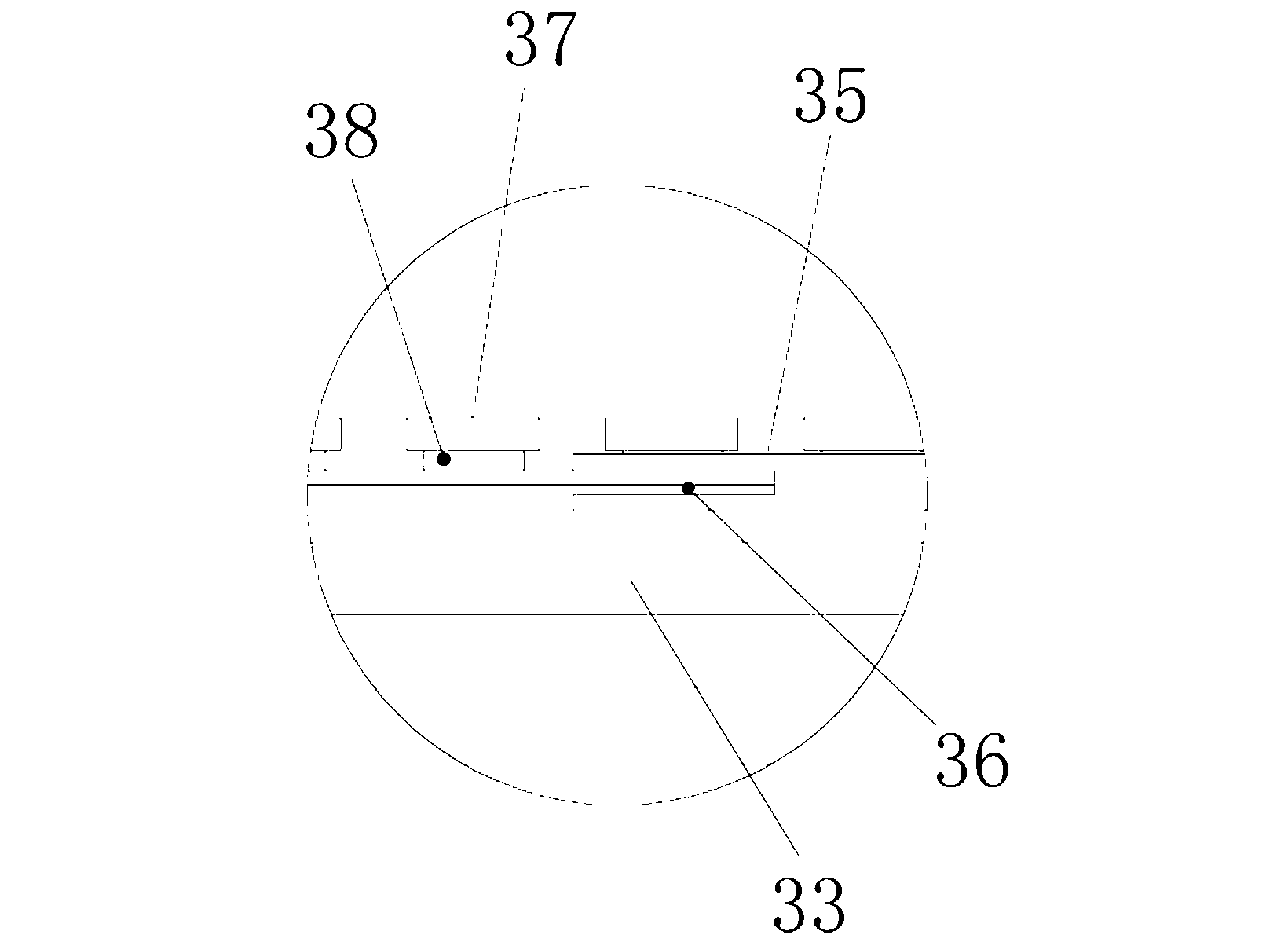

[0017] Wherein, the plate feeding device includes a slide rail 31, the end of the slide rail 31 is equipped with a servo motor 32, the inside of the slide rail 31 is installed with a screw rod 33 driven by the servo motor 32, and the top of the slide rail 31 is equipped with a The screw rod 33 drives the sliding block 34 that translates. Further, the front end of the slider 34 is installed with a push rod 35 for transferring the plate, and the front end of the push rod 35 is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com