Hollow harmonic speed reduction device with deep-groove ball bearing

A technology of deep groove ball bearings and harmonic deceleration, applied to components with teeth, transmission boxes, etc., can solve problems such as high requirements for parts installation, inconvenient equipment adjustment and maintenance, complicated and cumbersome assembly of harmonic reducers, etc., to achieve Save installation time, facilitate inspection and maintenance, and ensure firmness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

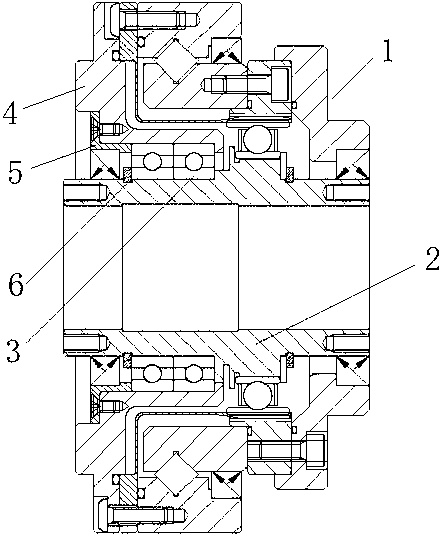

[0012] attached figure 1 It is a hollow harmonic deceleration device with deep groove ball bearings according to the present invention, which includes a harmonic decelerator 1, a hollow input shaft 2, and a deep groove ball bearing 3; the hollow input shaft 2 is arranged on the harmonic deceleration In the device 1; the harmonic reducer 1 is provided with a bearing fixing assembly; the deep groove ball bearing 3 is arranged between the hollow input shaft 2 and the bearing fixing assembly; the bearing fixing assembly includes a bearing seat 4 and a bearing pressure plate 5. The bearing seat 4 and the bearing pressure plate 5 respectively fix the two ends of the deep groove ball bearing 3 ; on the outer circumference of the hollow input shaft 2 , a stop ring 6 is provided near the deep groove ball bearing 3 .

[0013] Due to the application of the above-mentioned technical solution, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com