Automatic electromagnetic partition-changing and positioning device of full-automatic cleaning device for tubular heater

A tubular heater, fully automatic cleaning technology, used in lighting and heating equipment, cleaning heat transfer devices, flushing, etc., can solve the problem of unreliable, large-diameter ring rails, complicated manufacturing and installation, increased mechanical structure and control Part of the complexity and other issues, to achieve the effect of good reliability, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

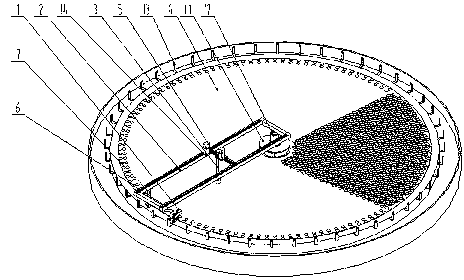

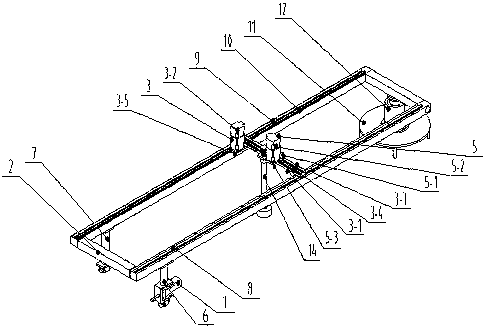

[0014] Referring to Fig. 1 and Fig. 2, the positioning block 13 is evenly welded on the circular plane at the edge of the heater 4, and the heating tube of the heater 4 is divided into several cleaning areas. The installation spacing of the positioning blocks 13 is smaller than the effective range of the y-axis sliding of the y-axis driving device 5 on the x-axis driving device 3 . Frame central positioning seat 11 is welded on the heating pipe center of heater 4. The frame 2 is made of square steel, and the lower part in the middle of one end of the frame 2 is equipped with a central rotating device 12 and connected to the center positioning seat 11 of the frame. The frame center positioning seat 11 rotates. The bottom of frame 2 other ends is equipped with caster 7 and positioning caster 6 and can rotate around the circular plane of heater 4 edges, and positioning device 1 is installed along the radial direction of heater 4 on the positioning caster 6. After dividing the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com