An automated droplet mixing chip with a single plane and a single electrode control method thereof

A single-plane, droplet technology, applied in mixers, chemical instruments and methods, dissolution, etc., can solve problems such as being unsuitable for portable instruments, unsuitable for portable instruments, and difficult to react reagents, and achieve high reliability and simple graphics. and structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

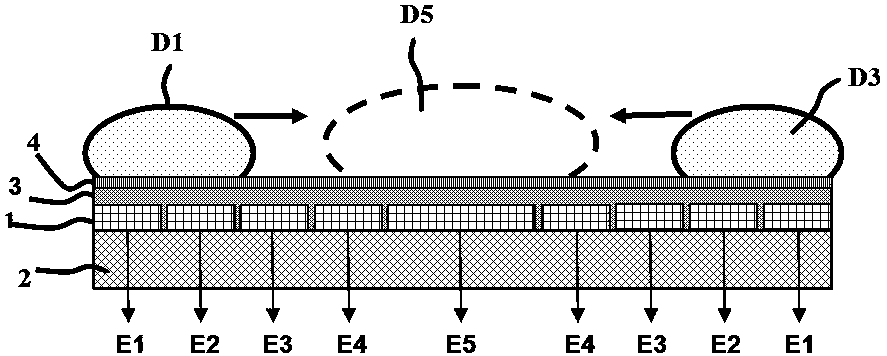

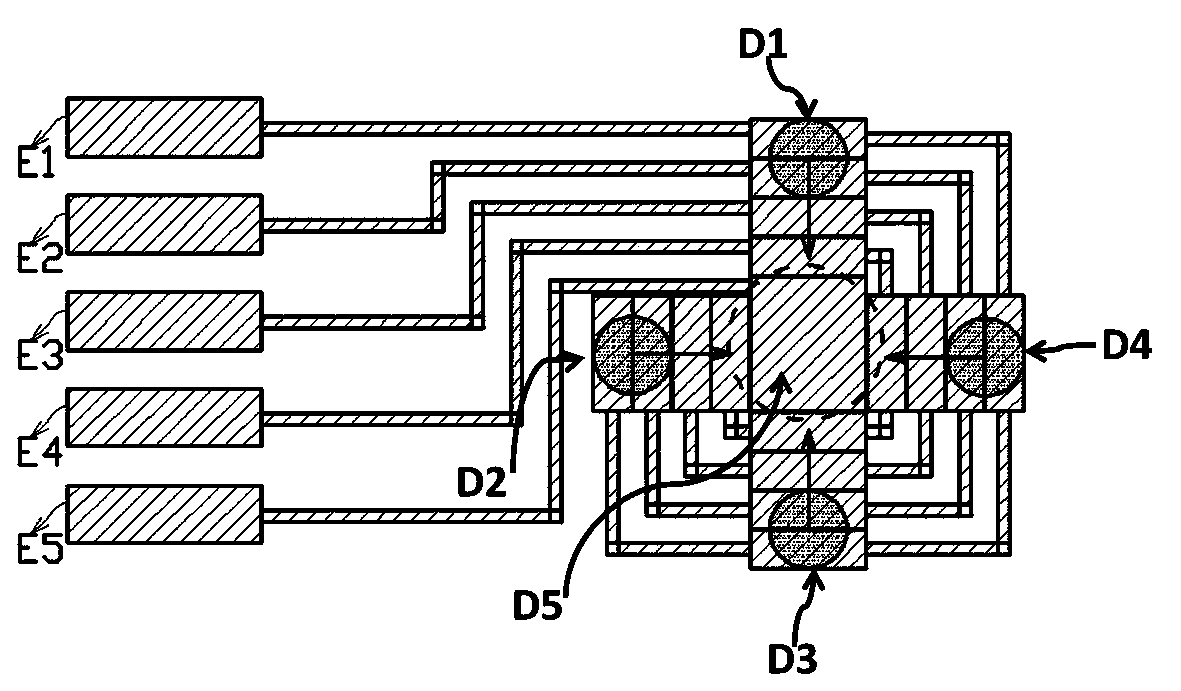

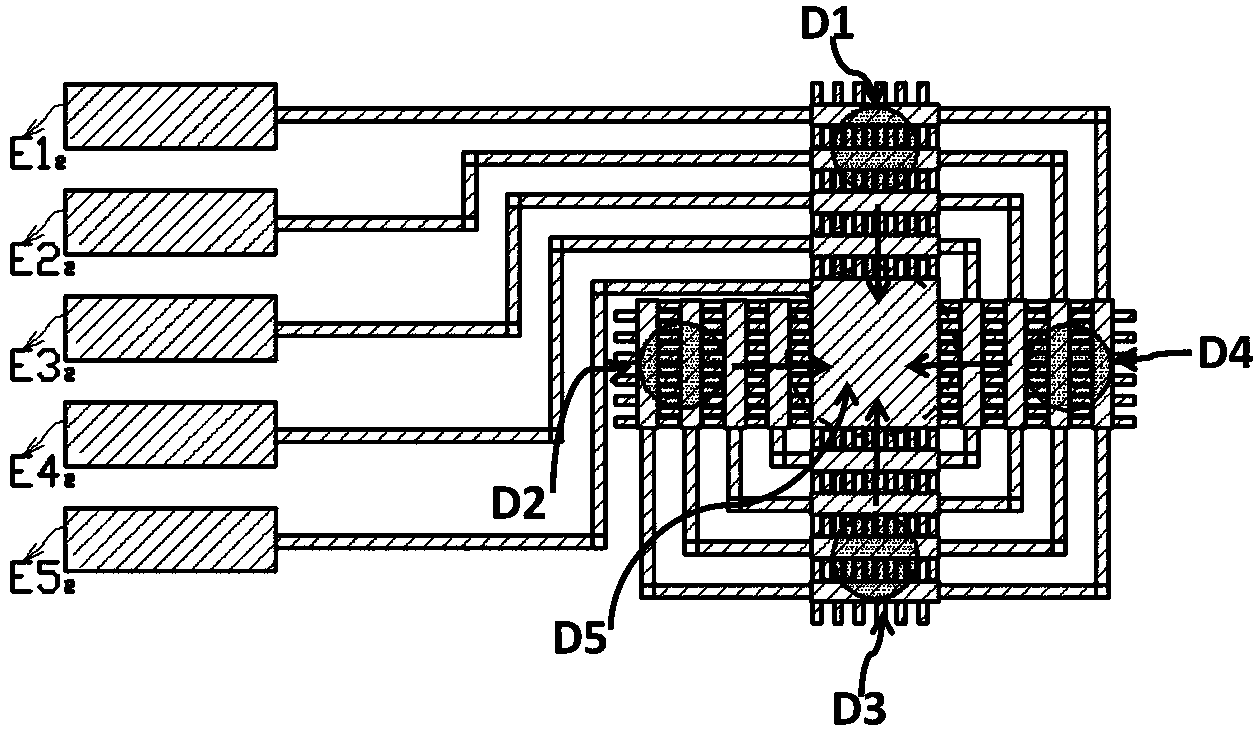

[0038] like figure 1As shown, it is a schematic cross-sectional view of the droplet mixing zone in Embodiment 1 of the present invention, and the cross-section direction passes through the center of the control electrodes radially distributed in the shape of a "cross" in the droplet mixing zone along the longitudinal direction. From the perspective of the cross-sectional structure, the chip structure of the present invention can be divided into insulating substrate 2 from bottom to top, and the above-mentioned insulating substrate 2 can generally use a silicon wafer or a glass substrate with an oxidized insulating layer on the surface; The control electrodes 1 are radially distributed, and each control electrode 1 is connected to each lead electrode E1-E5 in the signal input area through a circuit. The metal oxide of the above-mentioned control electrode 1 is covered with a layer of insulating dielectric layer 3 by deposition or spin-coating method, and the material of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com