Railway catenary comprehensive operation vehicle body

A catenary and work vehicle technology, applied in the direction of railway car body, railway car body parts, railway transportation, etc., can solve the problems of heavy weight and difficulty in adapting to high-speed running, etc., and achieve the effect of simple structure and easy processing and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

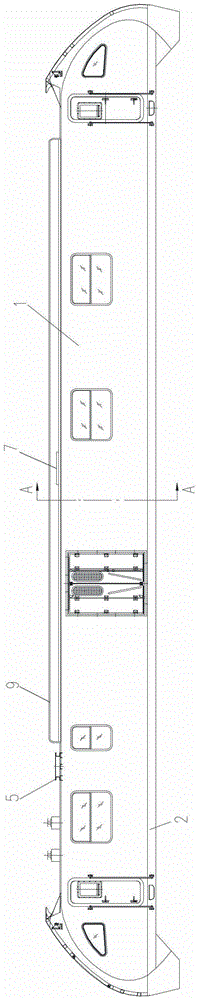

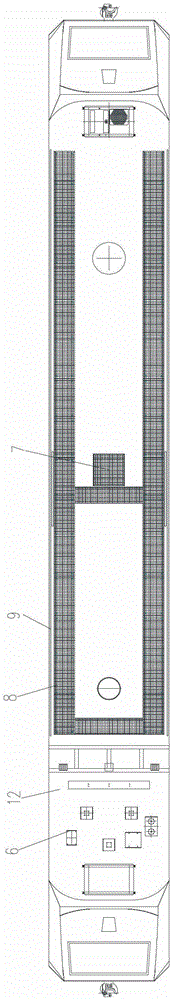

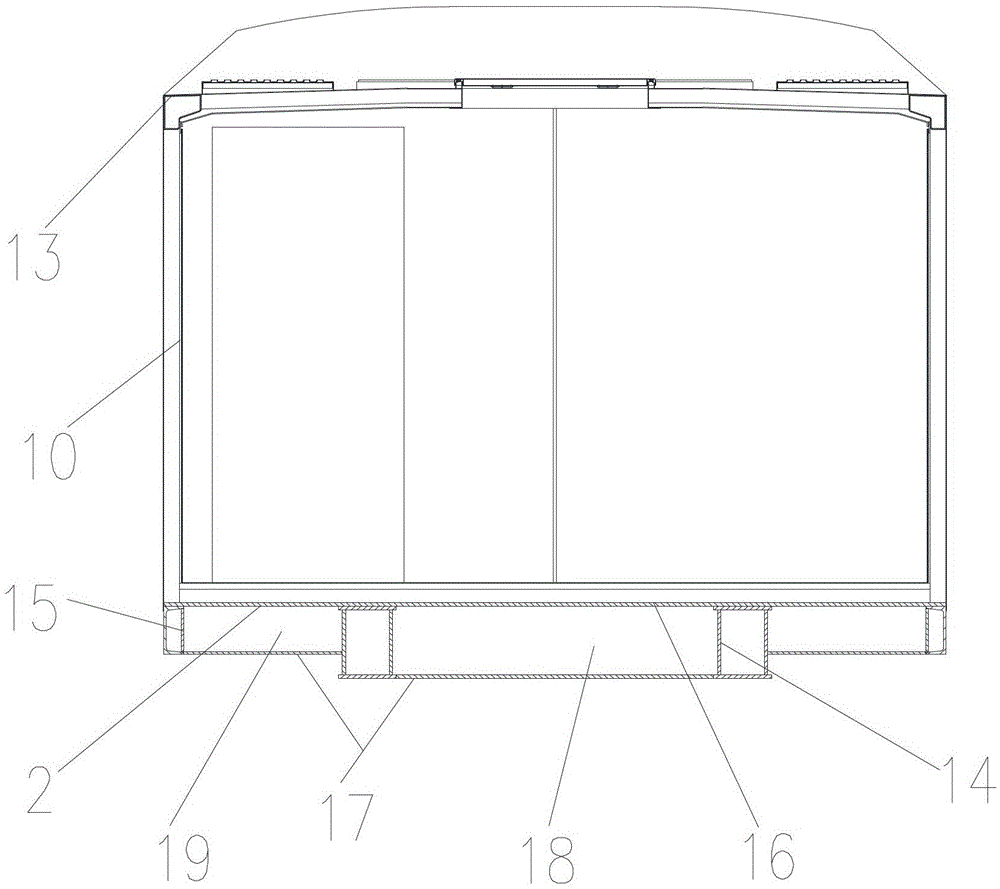

[0017] Attached below Figure 1-4 An embodiment of the present invention is described.

[0018] The body of the railway catenary operation vehicle includes a body 1 and an underframe 2, the body 1 is fixed on the upper end of the underframe 2, specifically, the body 1 includes a side wall 11 and a ceiling 12, and the side wall 11 is a hollow structure And its lower end is directly welded on the bottom frame 2, and the inner cavity of the upper end of the side wall 11 is provided with a plurality of upper string beams 13, and both ends of the ceiling 12 are fixed on the top string beams 13 to form an integral frame with the side wall 11 and the bottom frame 2. load bearing structure. The underframe 2 includes two hollow center beams 14 and two hollow side beams 15, and the upper ends of the two hollow center beams 14 and the two hollow side beams 15 are fixed with a cover plate I16, and are connected with the two hollow center beams 14 and the two hollow side beams 15. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com