Bilateral driving type annular guide rail chip transmission device

An annular guide rail, bilateral drive technology, used in transportation, packaging, conveyors, etc., can solve the problem of not meeting the material transmission requirements of integrated circuit packaging production lines, increasing the resistance of transmission, mechanical vibration, and easy formation of sliders and guide rails. Including angle and other issues, to achieve the effect of strengthening stability, reducing mechanical vibration and transmission resistance, reducing transmission resistance and mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

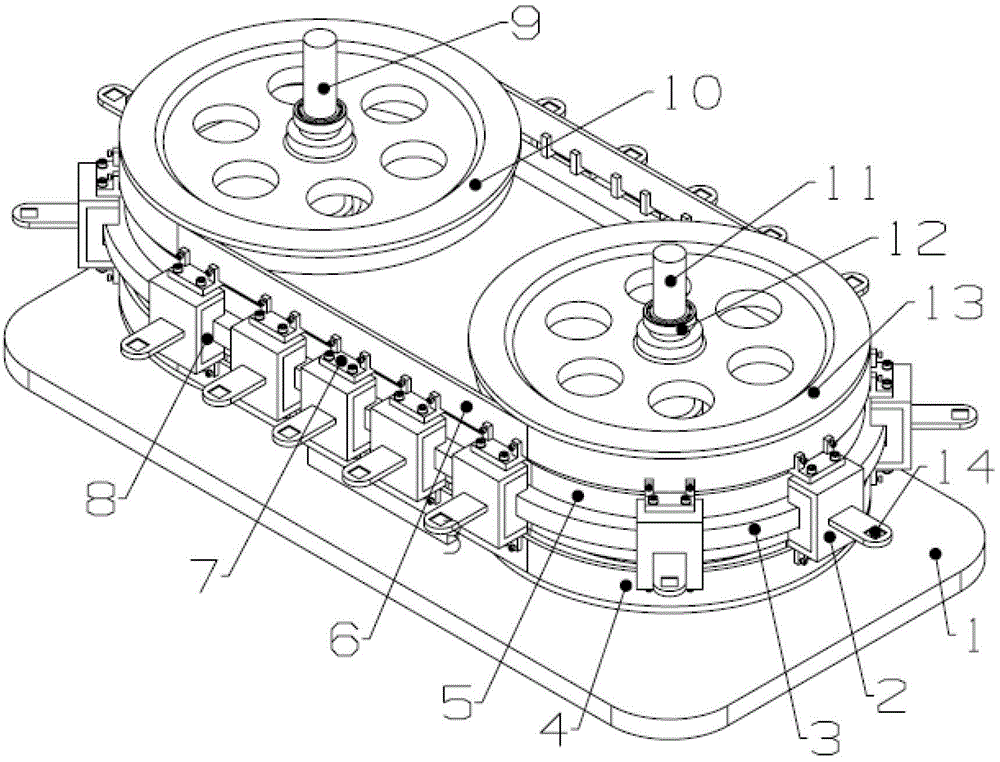

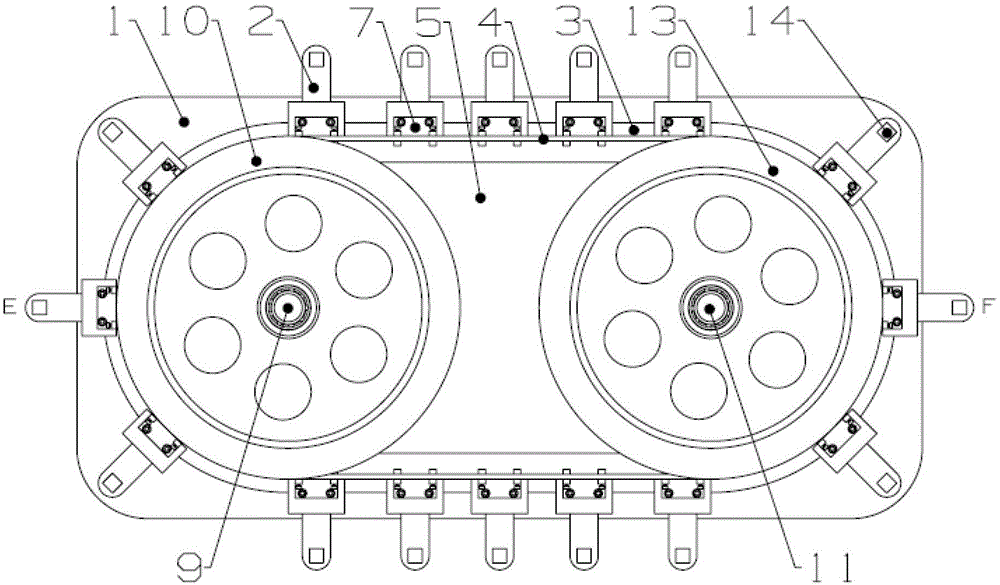

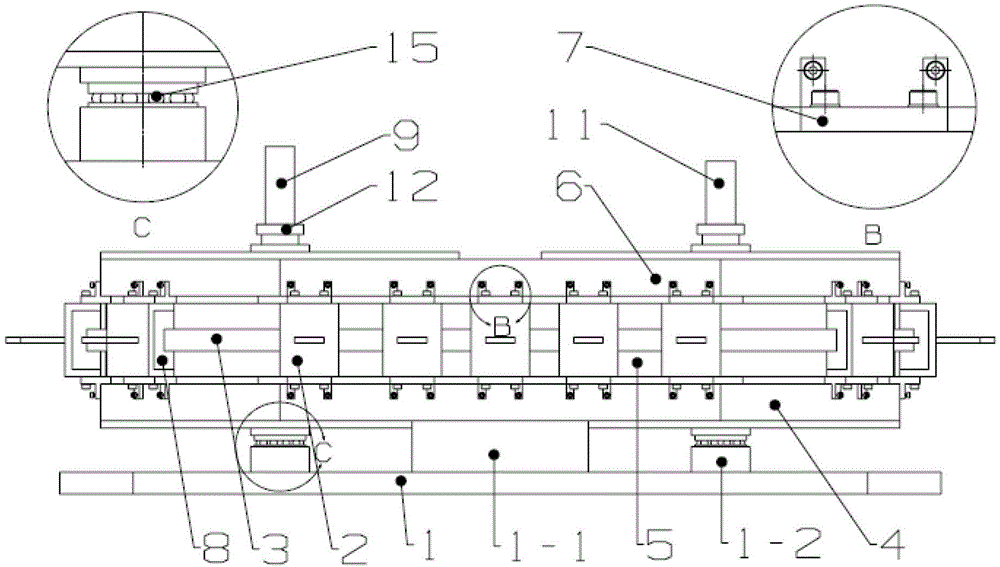

[0027] like Figure 1~4 As shown, the double-sided drive ring guide rail chip transfer device of the present invention includes a base 1, and a synchronous transmission mechanism, a ring guide rail sliding mechanism and a loading mechanism arranged on the base 1, wherein:

[0028] The base 1 has a support frame 1-1 and two bosses 1-2, and the two bosses 1-2 are located on both sides of the support frame 1-1 and symmetrical to the center of the support frame 1-1.

[0029] The synchronous transmission mechanism includes a driving shaft 11 and a driven shaft 9, and the lower ends of the driving shaft 11 and the driven shaft 9 are respectively installed on two bosses 1-2 on the base 1 using one-way thrust ball bearings 15, The upper driving synchronous pulley 13 and the lower driving synchronous pulley 17 are fixed coaxially on the driving shaft 11 from top to bottom, and the upper driven synchronous pulley 10 is coaxially fixed on the driven shaft 9 from top to bottom. and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com