A three-channel balance ring

A balancing ring and three-channel technology, which is used in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of limited rectification ability, the size and shape of the runner, the limitation of the rectification ability, the influence of the rectification ability, etc., so as to improve the rectification ability. , The effect of improving the deviation correction ability and reducing the number of barrel hits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

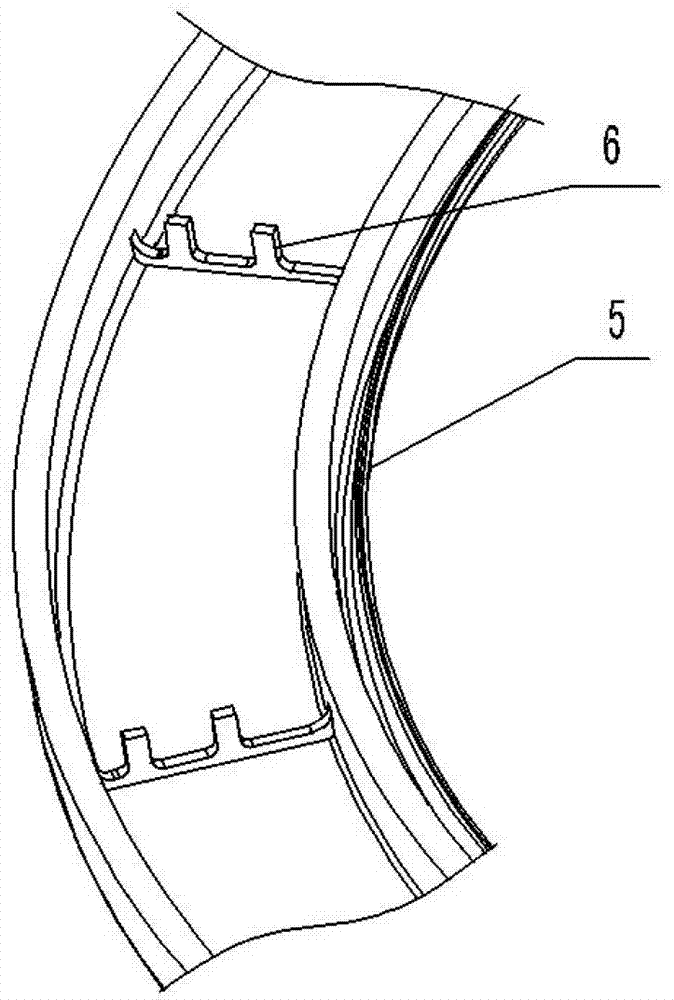

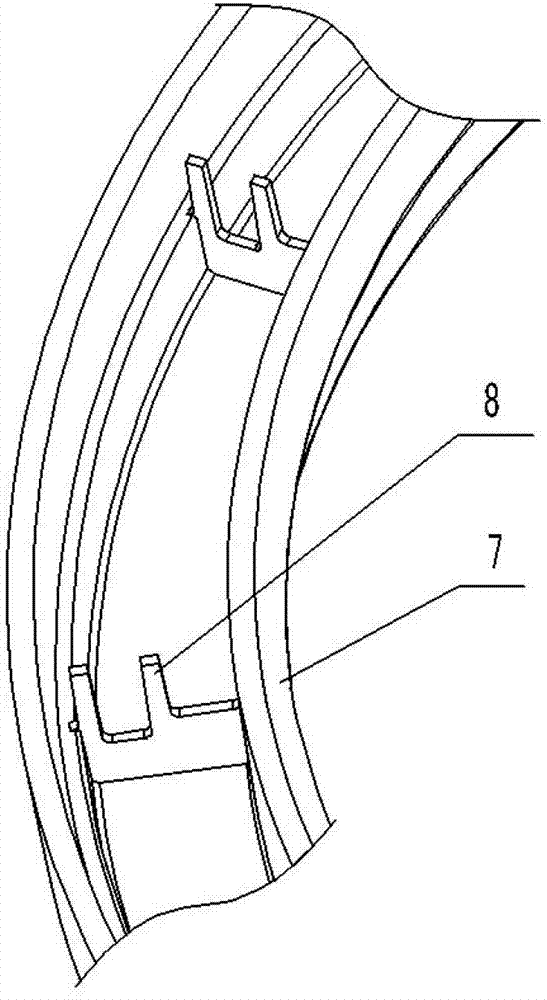

[0023] In specific implementation, such as figure 2 and image 3 As shown, the balance ring is divided into the lower half ring 7 of the upper half ring 5, and the partition is composed of upper ribs 6 and lower ribs 8 located at the same circumferential position in the upper half ring 5 and the lower half ring. Composed in pairs to form the gimbal 9.

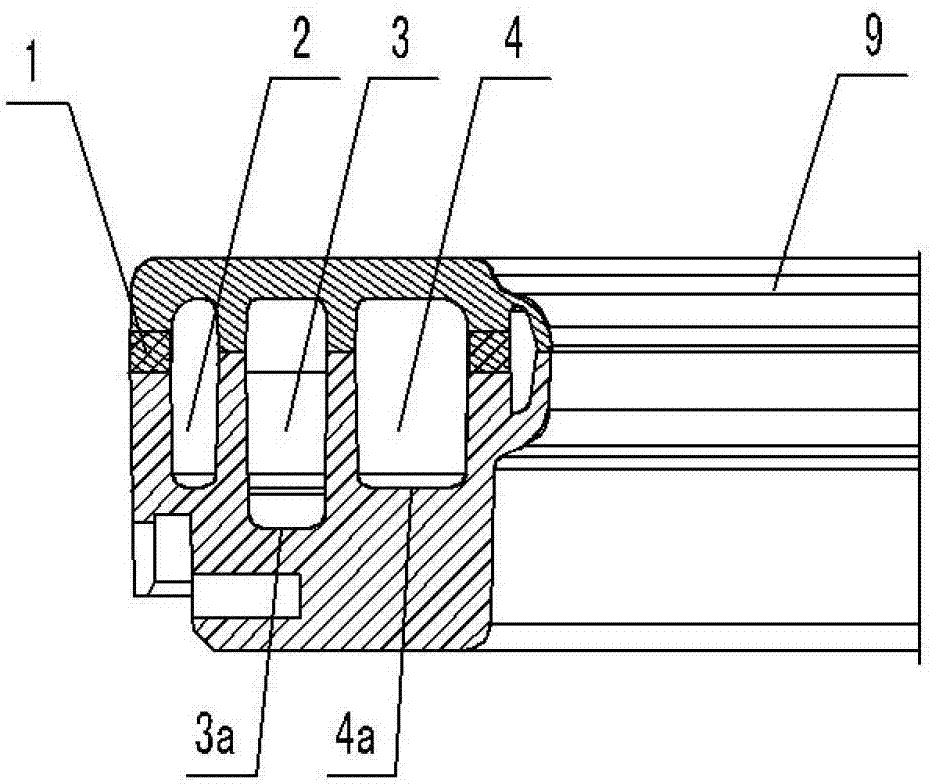

[0024] see figure 1 , the structural form of the three-channel gimbal in this embodiment is:

[0025] On the cross-section of the circular inner cavity of the balance ring, dividers are arranged at intervals along the circumference, and three flow passages independent of each other are set on the dividers, and the centers of the three flow holes are located in the ring. The different circumferential radius positions of the cavity are the high-speed flow channel 2 on the outer circumference, the low-speed flow channel 4 on the inner circumference, and the transition flow channel 3 between the high-speed flow channel 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com