Self-waterproof system of building external wall structure and construction method of self-waterproof system

A technology for building exterior walls and construction methods, which is applied to building components, building structures, buildings, etc., can solve problems such as leakage of exterior walls, improve waterproof capabilities, avoid leakage of exterior walls, and avoid common quality problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Formwork design is carried out according to the concrete member form, load size, construction equipment and other contents in the drawing design, and the construction process is prepared. The formwork material selected should be accurate in shape and size, with tight joints and sufficient strength and rigidity to improve the accuracy of component forming dimensions and prevent honeycomb phenomenon from formwork leakage.

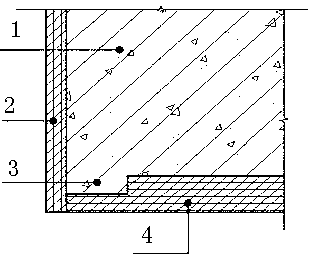

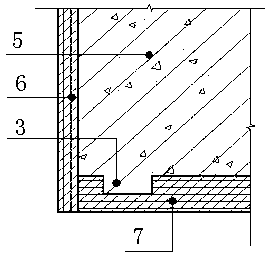

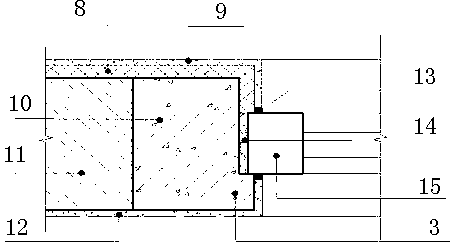

[0026] (2), such as figure 1 As shown, the outer side and bottom of the wall and beam concrete structure 1 are respectively provided with wall and beam outer formwork 2 and 4, and wall and beam bottom formwork. Such as figure 2 As shown, the column outer formwork 6 and column side formwork 7 are respectively provided on the outside of the column concrete structure 5 . Set up a water-blocking sill groove on the edge of the wall and beam bottom formwork 4 on the outer wall, and set a water-blocking sill groove at a distance of 8mm from the edge o...

Embodiment 2

[0034] (1) Formwork design is carried out according to the concrete member form, load size, construction equipment and other contents in the drawing design, and the construction process is compiled. The formwork material selected should be accurate in shape and size, with tight joints and sufficient strength and rigidity to improve the accuracy of component forming dimensions and prevent honeycomb phenomenon from formwork leakage.

[0035] (2), such as figure 1 As shown, the outer side and bottom of the wall and beam concrete structure 1 are respectively provided with wall and beam outer formwork 2 and 4, and wall and beam bottom formwork. Such as figure 2 As shown, the column outer formwork 6 and column side formwork 7 are respectively provided on the outside of the column concrete structure 5 . Set up a water-blocking sill groove on the edge of the wall and beam bottom formwork 4 on the outer wall, and set a water-blocking sill groove at a distance of 10mm from the edge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com