Vibration assisted well drilling simulation device

A simulation device and drilling technology, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of slow drilling speed and low efficiency, and achieve the effect of speeding up drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

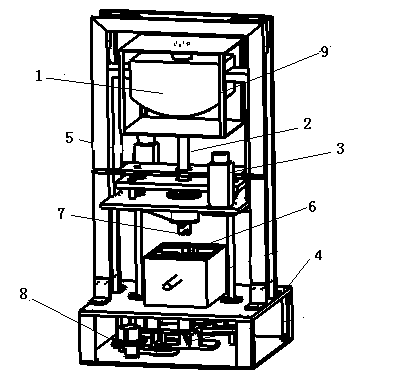

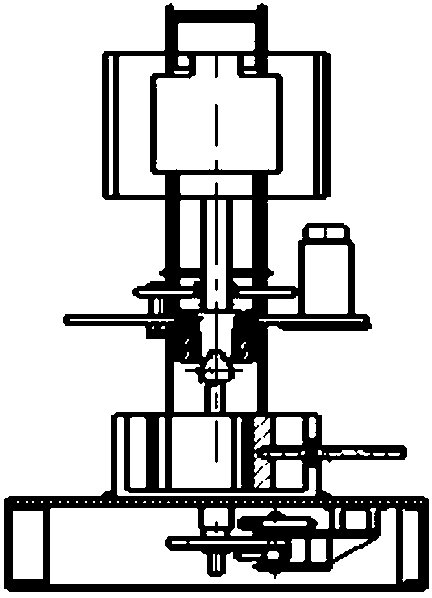

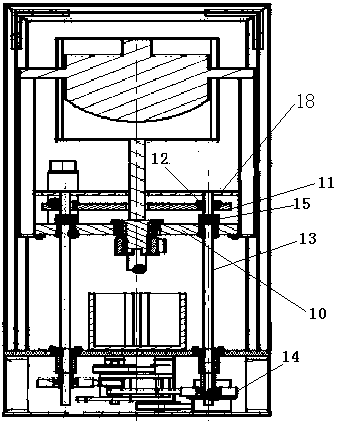

[0031] Such as figure 1 , 2 , 3, the vibration-assisted drilling simulation device includes a frame 4, a servo motor 8, a clamping device 6, two screw nut mechanisms, two jacks 16, a drill bit 17, a load plate 10, a load plate 11, and a rotating motor 3. Exciting table 1, square frame 9 and shock rod 2. Columns 5 are installed at both ends of the frame 4 .

[0032] A clamping device 6 is installed on the base plate of the frame 4, a servo motor 8 is installed at the bottom of the base plate, and gears are installed on the motor shaft of the servo motor 8. Lead screw nut mechanism is symmetrically arranged on both sides of clamping device 6, and the lower end of lead screw 13 passes through the frame bottom plate and is connected to the gear on the servo motor 8 motor shaft by the gear on the lead screw and the synchronous toothed belt 14, the lead screw The upper end of 14 passes through the bearing plate 10 and the loading plate 11 successively, and the nut 12 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com